Adjustments, Warning, Positive 0° bevel stop – Ryobi P500 User Manual

Page 21: Checking positive 0° bevel stop, Adjusting positive 0° bevel stop, Adjusting the laser

20

21

1

2

45

0

0

15

22

30

45

50

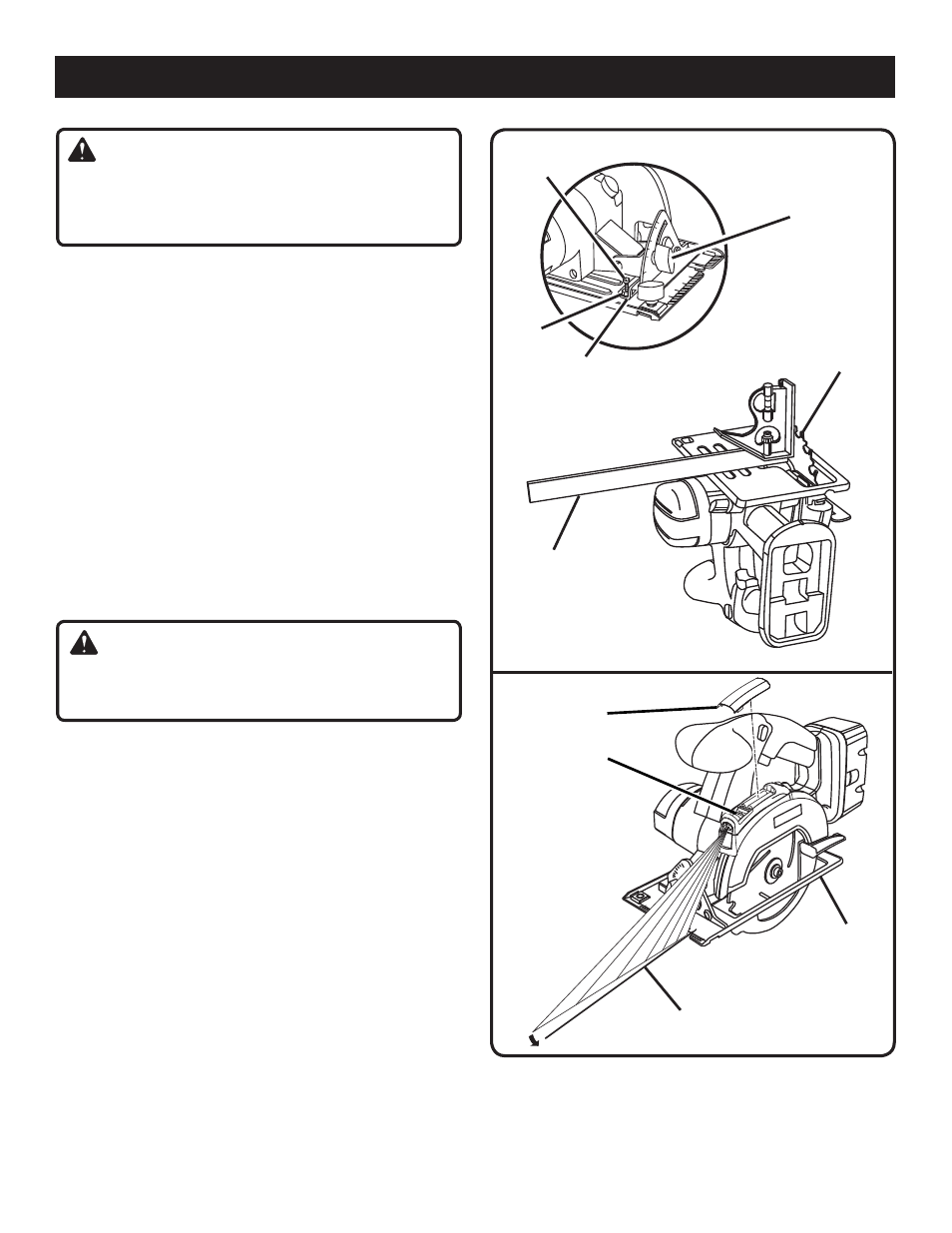

Fig. 24

BEVEL

ADJUSTMENT

KNOB

BLADE

CARPENTER'S

SQUARE

ADJUSTMENT

SCREW

HEX NUT

POSITIVE 0°

BEVEL STOP

ADJUSTMENTS

WARNING:

Before performing any adjustment, make sure the bat-

tery pack is removed from tool and the switch is in the

OFF position. Failure to heed this warning could result in

serious personal injury.

POSITIVE 0° BEVEL STOP

See Figure 24.

The saw has a positive 0° bevel stop that has been factory

adjusted to assure 0° angle of the saw blade when making

90° cuts.

CHECKING POSITIVE 0° BEVEL STOP

n

Place the saw in an upside down position on a work-

bench.

n

Check the squareness of the saw blade to the base of

the saw using a carpenter’s square.

ADJUSTING POSITIVE 0° BEVEL STOP

n

Loosen bevel adjustment knob.

n

Turn setscrew with hex key and adjust base until it is

square with the saw blade.

n

Tighten bevel adjustment knob securely.

WARNING:

Attempting a bevel cut without having the bevel ad-

justment knob securely tightened can result in serious

injury.

ADJUSTING THE LASER

See Figure 25.

�NOTE: Draw a pencil line on a scrap workpiece parallel to

the long edge of the base as a straight line guide to aid in

the adjusting process.

n

Make sure the laser is turned off.

n

Remove the laser cover by lifting it off its base.

�n Turn the laser on.

�n Loosen the screw inside the laser.

�n Rest the front of the base on a scrap workpiece.

n

Adjust the laser beam with the mark on the scrap

workpiece by loosening the screw to the laser aperture

and slowly moving the laser guide left or right.

n

Since blade thicknesses vary, always make a trial cut in

scrap workpiece to ensure an accurate cut.

�n Once alignment is achieved, tighten the screw.

�n Replace the laser cover.

n

Check for proper alignment.

�n Repeat as necessary until the laser is aligned.

LASER

COVER

SCREW

Fig. 25

PENCIL

LINE

LONG EDGE

OF BASE