Т³гж 15 – Reliable MSK-8900M User Manual

Page 16

34

34

Stritch

0~0.5mm

0~0.5mm

<-3>

1.8mm

<-5>

2.2mm

<-3>

1.8mm

<-5>

2.2mm

0.05mm

0.05mm

b

b

35

35

Most

Least

More

less

33

33

Timing fast Starelarcl Timing slow

A

A

B

B

<-3>

<-3>

<-5>

<-5>

For example: MSK-8900M

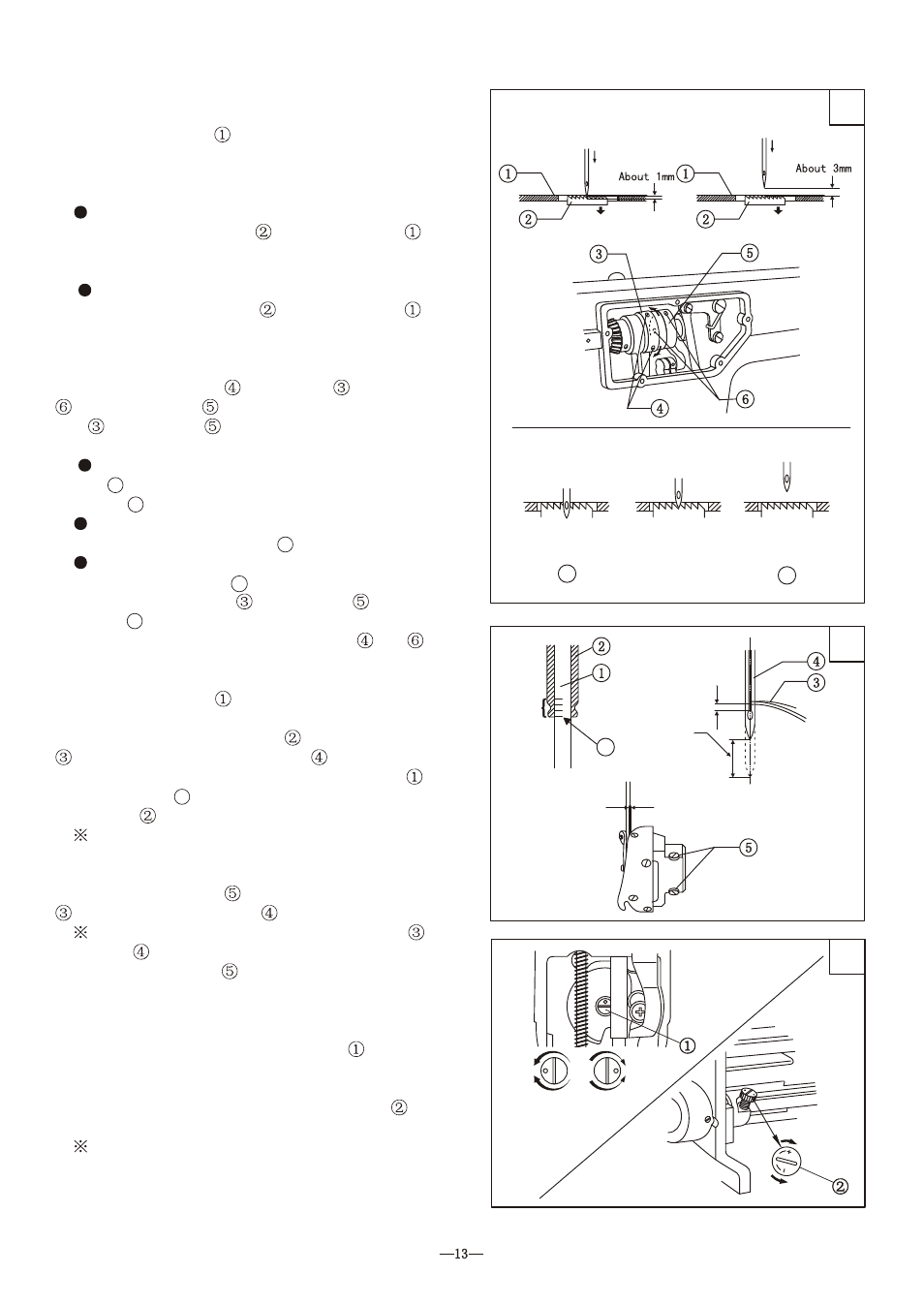

7. Adjust the position between needle bar and feed

dog (Fig.33)

When the feed dog

moves down to the position

which is same with the surface of needle plate from its

highest position,the standard position of needle should

be as follows:

For light and medium weight materials

The surface of feed dog

and needle plate

should be same and the pinpoint of needle is 1mm

lower than the needle plate

For heavy weight materials

The surface of feed dog

and needle plate

shousd be same and there is a clearance of 3mm

between the pinpoint and needle plate

(1) Uninstall the back cover;

(2) Loosen the screw

on the cam

and screw

on the feed cam

, slightly turn and adjust the

cam

and feed cam

( these two cams are connect

-ed by pin and should turn alternative side)

If the timing of needle is fast, turn as shown in

the Fig.

A

; if the timing of needle is slow, turn as shown

in the Fig.

B

For avoiding materials misplacing, please make

the timing of needle slowly (Fig.

B

)

For avoiding stitch puckering, please make the

timing of needle fast (Fig.

A

)

Notice: If turn the cam

and feed cam

overlar

-ge as Fig.

A

Shown , it will make needle broken

(3) After adjustment, tighten the screw

and

8. Adjust the position between needle and hook

(Fig.34)

Lift the needle bar

from its lowest position ,

while the lowest mark on the needle bar aligns with

the bottom of needle bar bushing

, the tip of hook

should aim at the center of needle

.

(1) Turn the hand wheel and lift the needle bar

to make the mark b align with the bottom of needle

bar bushing

When the needle is lifted 1.8mm (for MSK-8900M)

or 2.2mm (for MSK-8900H), the clearance between the

hole of needle and the tip of hook should be 0~0.5mm

(2) Loosen the screw

and make the tip of hoodk

aim at the center of needle

.

the lateral clearance between the tip of hook

and needle

. should be 0.05mm

(3) tighten the screw

9. Adjust the oil amount of upper shaft and hook

(Fig.35)

(1) Upper shaft

Uninstall the face plate, turn the screw

to adjust

the oil amount of upper shaft

(2) Hook

Lay down the machine head, turn the screw

to

adjust the oil amount of hook.

After adjustment, let the machine be run for 2~3

mim. and confirm the oil amount again