Maintenance – RedMax PSZ2450S User Manual

Page 14

Maintenance, replacement, or repair of the emission control device and systems may be performed by any

non-road engine repair establishment or individual.

US-14

PSZ2450S

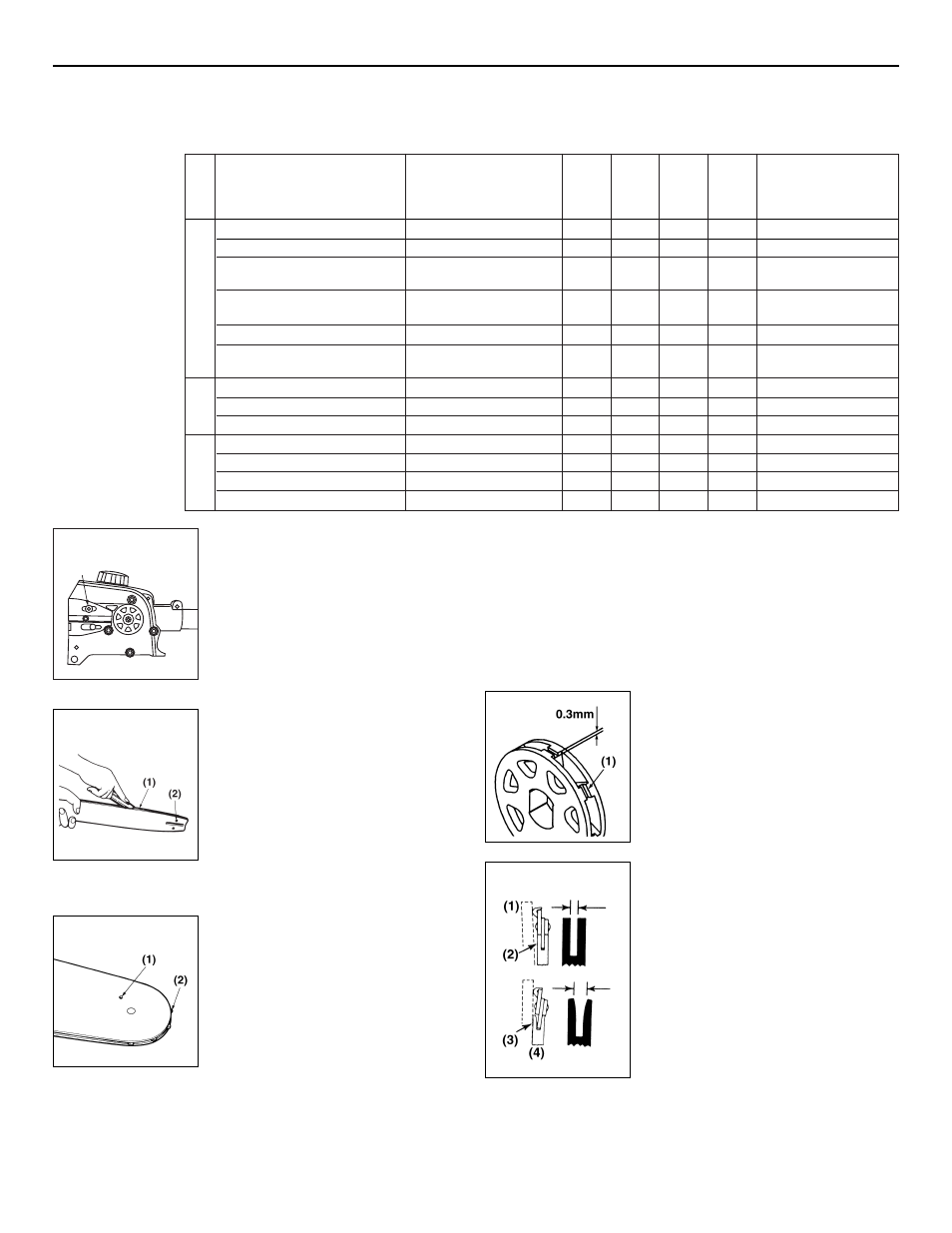

■ OILING PORT

Dismount the guide bar and check the

oiling port for clogging. (MA1)

(1) Oiling port

■ GUIDE BAR

Remove sawdust in the bar groove and

the oiling port. (MA2)

(1) Groove

(2) Oiling port

(Type: Sprocket nose)

Grease the nose sprocket from the

feeding port on the tip of the bar. (MA3)

(1) Grease port

(2) Sprocket

■ OTHERS

Check for fuel leakage and loose

fastenings or damage to major parts,

especially housing joints and guide bar

mounting. If any defects are found, make

sure to have them repaired before

operating again.

■ SPROCKET

Check for extensive wear, and replace it

when the teeth are worn over 0.3mm.

(MA4)

(1) Sprocket

■ GUIDE BAR

The bar rail should always be a square.

Check for wear of the bar rail. Apply a

ruler to the bar and the outside of a cutter.

If a gap is observed between them, the

rail is normal. Otherwise, the bar rail is

worn. Such a bar needs to be corrected or

replaced.(MA5)

(1) Ruler

(2) Gap

(3) No gap

(4) Chain tilts

9. Maintenance

Every

Every

Every

25

50

100

System/compornent

Procedure

Before

hours

hours

hours

note

use

after

after

after

fuel leaks, fuel spillage

wipe out

✔

fuel tank, air filter, fuel filter

inspect/clean

✔

✔

replace, if necessary

see

■ADJUSTING

replace carburetor

idle adjusting screw

✔

IDLING SPEED (p.13)

if necessary

clean and readjust

GAP: .025in(0.6~0.7 mm)

spark plug

✔

electrode gap

replace, if necessary

cylinder fins, intake air cooling vent

clean

✔

muffler, spark arrester,

clean,

✔

cylinder exhaust port

remove piled up carbon

throttle lever, ignition switch

check operation

✔

gear case

grease

✔

screws/nuts/bolts

tighten/replace

✔

✔

not adjusting screws

oiling port

clean

✔

guide bar

clean

✔

sprocket

inspect/replace

✔

saw chain

inspect/replace

✔

ENGINE

SHAFT

CUTTING UNIT

■ MAINTENANCE CHART

(1)

MA1

MA2

MA3

MA4

MA5