Operation, Warning – Ryobi HD1830 User Manual

Page 17

Page 17

OPERATION

WARNING:

Always wear safety goggles or safety glasses with side

shields when operating tool. Failure to do so could result

in dust, shavings, or loose particles being thrown into

your eyes, resulting in possible serious injury.

DRILLING

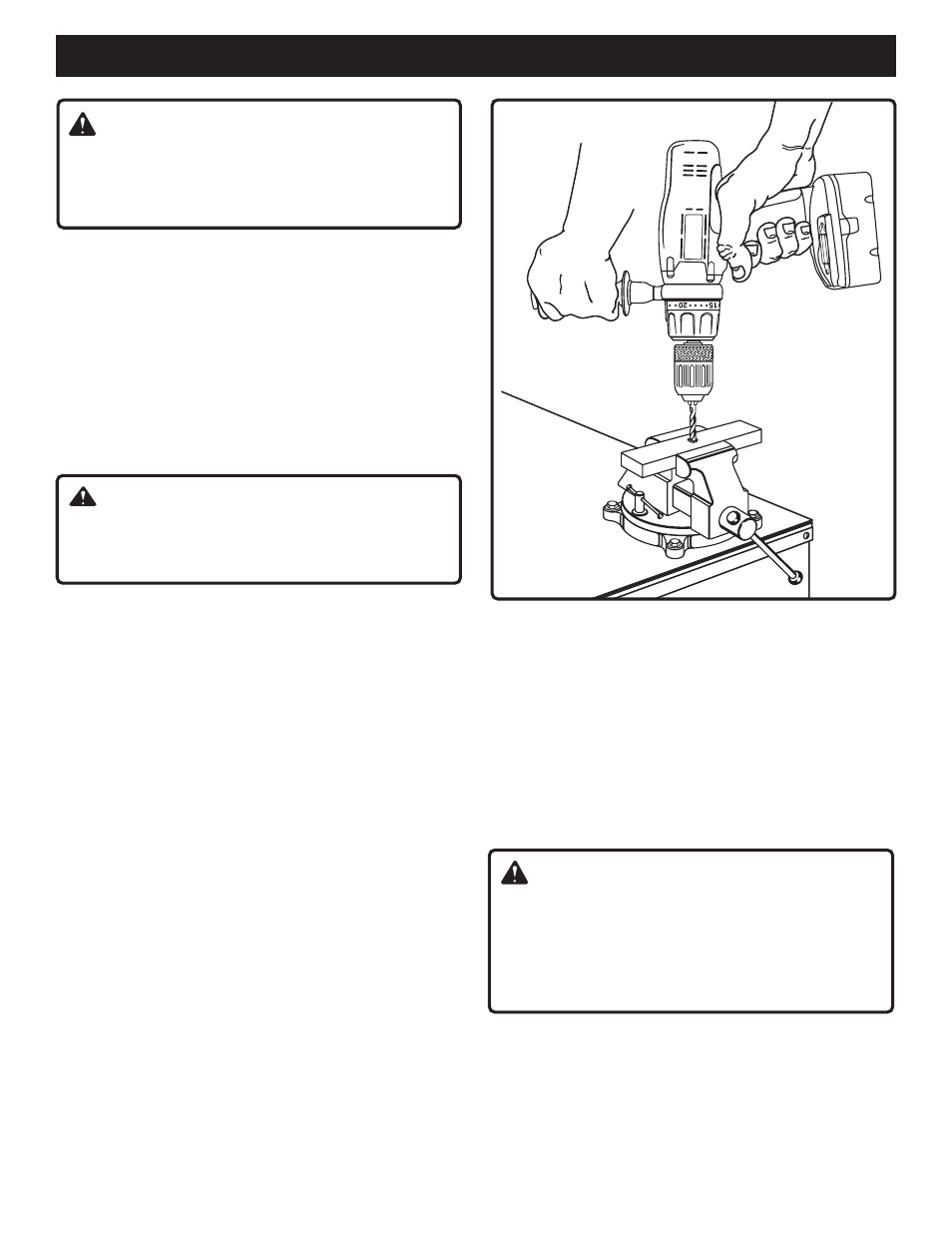

See Figure 15.

The material to be drilled should be secured in a vise or with

clamps to keep it from turning as the drill bit rotates.

Hold tool firmly and place the bit at the point to be drilled.

Depress the switch trigger to start tool.

Move the drill bit into the workpiece, applying only enough

pressure to keep the bit cutting. Do not force or apply side

pressure to elongate a hole.

We recommend that you select normal drill mode when

drilling with twist drills, hole saws, etc., in soft material.

WARNING:

Do not force tool. Forcing tool can result in jamming and

loss of balance or footing, which could result in personal

injury.

When drilling hard, smooth surfaces, use a center punch to

mark the desired hole location. This will prevent the drill bit

from slipping off center as the hole is started. However, the

lower speed feature allows starting holes without center

punching if desired. To accomplish this, simply operate your

drill at lower speed until the hole is started.

For drilling in wood, begin drilling at LO (1) speed, gradu-

ally increasing to full power. Occasionally clear chips from

the bit to prevent overheating. Low speed bits should be

used when drilling larger holes.

When drilling metals other than brass and cast iron, use a

light oil on the drill bit to keep it from overheating. The oil will

prolong the life of the bit and increase the drilling action.

Begin drilling at LO (1) speed, gradually increasing to higher

speeds. When drilling larger holes in steel, it may be helpful

to first drill a smaller pilot hole.

We recommend that you use carbide-tipped bits and select

hammer mode when drilling in hard materials such as brick,

tile, concrete, etc.

This tool is packed with two double-ended screwdriver bits.

For driving screws, select the desired speed and torque

settings using the speed selector and torque adjustment

ring. Insert the screwdriver bits as you would a drill bit, as

shown in figure 6. You may need to drive a few practice

screws in the type of material you will be working with.

For using the hammer drill feature, rotate the torque

adjustment ring, as shown in figure 4, so that the hammer

symbol is aligned with the arrow. Using the auxiliary handle

will provide better control and prevent forcing the tool.

■ Hold the drill at a right angle as shown in figure 15. Do not

force or apply side pressure to elongate the hole.

■ If the hammer speed decreases while drilling deep holes,

it may be necessary to lift up partially on the tool to clear

debris from the hole.

■ If there is excessive dust while using the hammer feature,

do not add water to the hole. This can cause clogging and

binding of the bit.

■

If the bit jams in workpiece or if the drill stalls, release

switch trigger immediately. Remove the bit from the

workpiece and determine the reason for jamming.

WARNING:

Be prepared for binding or bit breakthrough. When these

situations occur, the drill has a tendency to grab and kick

opposite to the direction of rotation, and could cause loss

of control when breaking through material. If you are not

prepared, this loss of control can result in possible serious

injury.

Maximum Recommended Capacities

SPEED 1 SPEED 2 SPEED 3

Bits, Metal Drilling

1/2"

1/4"

1/4"

Wood, Flat Boring

1-1/2"

5/8"

3/8"

Bits, Masonry Drilling

-

1/4"

1/4"

Fig. 15