Electric chain saw, Assembly instructions, Saw chain tension adjustment – Remington Power Tools EL-3 User Manual

Page 4

4

101755

®

ELECTRIC CHAIN SAW

ASSEMBLY

INSTRUCTIONS

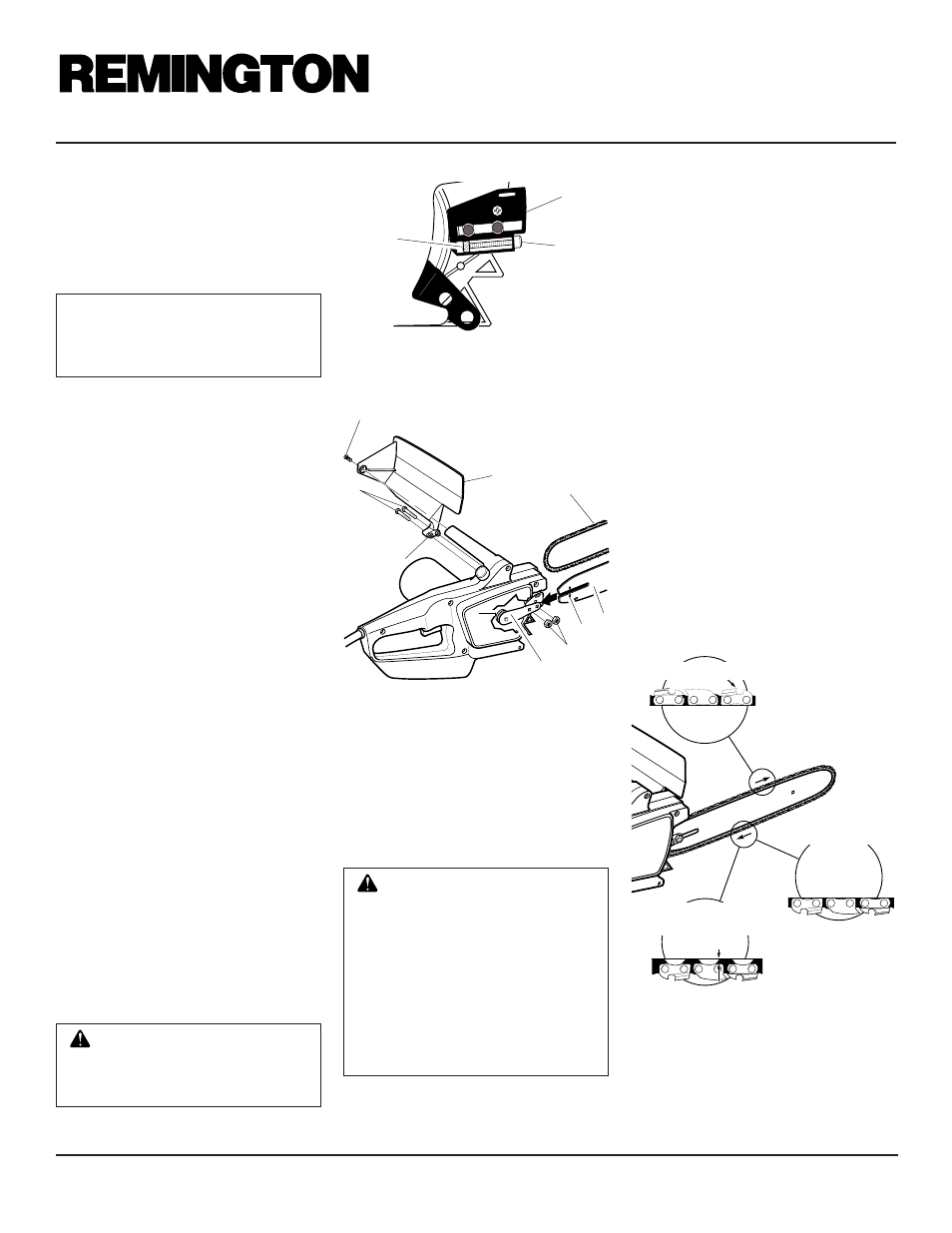

ASSEMBLING GUIDE BAR,

SAW CHAIN AND HAND

GUARD

IMPORTANT: Do not clamp in a

vise or abuse during assembly.

Always wear gloves when han-

dling the saw chain.

1.

Remove two (2) guide bar nuts (D), two

(2) guide bar bolts (E) and one (1)

Phillips screw (N) from the plastic bag.

2.

Lay the saw chain (C) out flat.

3.

Install hand guard (K) by press fitting

the two bosses (L) into the hex shaped

holes in the saw body. Install the

Phillips screw (N) into the hand guard

and saw handle and tighten securely.

4.

Turn adjusting screw (A)

counterclockwise to move the adjusting

block (B) as far as it will go to the rear

of the mount (See Figure 1).

5.

Slide the guide bar (G) on to the

adjusting plate (H) aligning adjusting

block (B) with the square adjusting hole

(I) in the guide bar.

6.

Rotate the sprocket support (F) back

over the guide bar so the holes line up.

7.

Insert ONLY the front guide bar bolt

(E) through the body of the saw and

through sprocket support (F). Tighten

the nut (D) only finger tight. This will

allow clearance for the installation of

the saw chain.

8.

Slide the saw chain between the side

cover and the sprocket (J), in the top

groove of the guide bar (G) and around

the guide bar nose.

9.

Insert remaining guide bar bolt (E) and

install nut (D) finger tight.

10. Adjust the saw chain tension by

following the tension adjustment

instructions.

CAUTION: If saw chain is as-

sembled backwards, the saw will

vibrate excessively and will not

cut.

B

H

A

Figure 1 - Part Locations For Assembling

Guide Bar

D

N

K

E

L

G

C

J

F

I

Figure 2 - Assembling Guide Bar, Chain,

and Hand Guard

SAW CHAIN

TENSION

ADJUSTMENT

CAUTION: The saw chain ten-

sion must be properly main-

tained. Failure to do so will cause

rapid saw chain, guide bar and

sprocket wear. A loose chain will

increase the possibility of kick-

back and may jump out of the

guide bar groove. This may cause

damage to the chain and injury to

the operator. Tighten guide bar

nuts securely.

1.

Before adjusting the saw chain, make

sure the guide bar nuts (D) are only

finger tight (See Figure 1 and 2).

2.

Turn adjusting screw (A) clockwise

until all slack is out of the saw chain.

3.

Wear protective gloves and pull the saw

chain (C) around the guide bar. It

should move freely.

4.

If necessary, readjust chain using

adjusting screw (A). There should be

no gap between the side links of the saw

chain and the bottom of the guide bar

(See Figure 3).

5.

Tighten guide bar nuts (D) using a

wrench. Nuts not tightened securely

will allow guide bar movement

resulting in loose chain and increasing

the possibility of kickback and damage

to mating parts.

6.

A new chain will stretch and should be

checked after the first few minutes of

operation. Disconnect saw from power

source. Adjust the chain tension after

it has had a few minutes to cool down.

Use protective gloves to protect hands

from chain teeth.

Figure 3 - Saw Chain Adjustment

Standard Chain

Cutting Edges Forward

Guide Bar

Guide Bar

Incorrect Saw

Chain Tension

Gap

Guide Bar

Correct Saw Chain

Tension