Maintenance and repair instructions – Ryobi RCT2800AD User Manual

Page 13

13

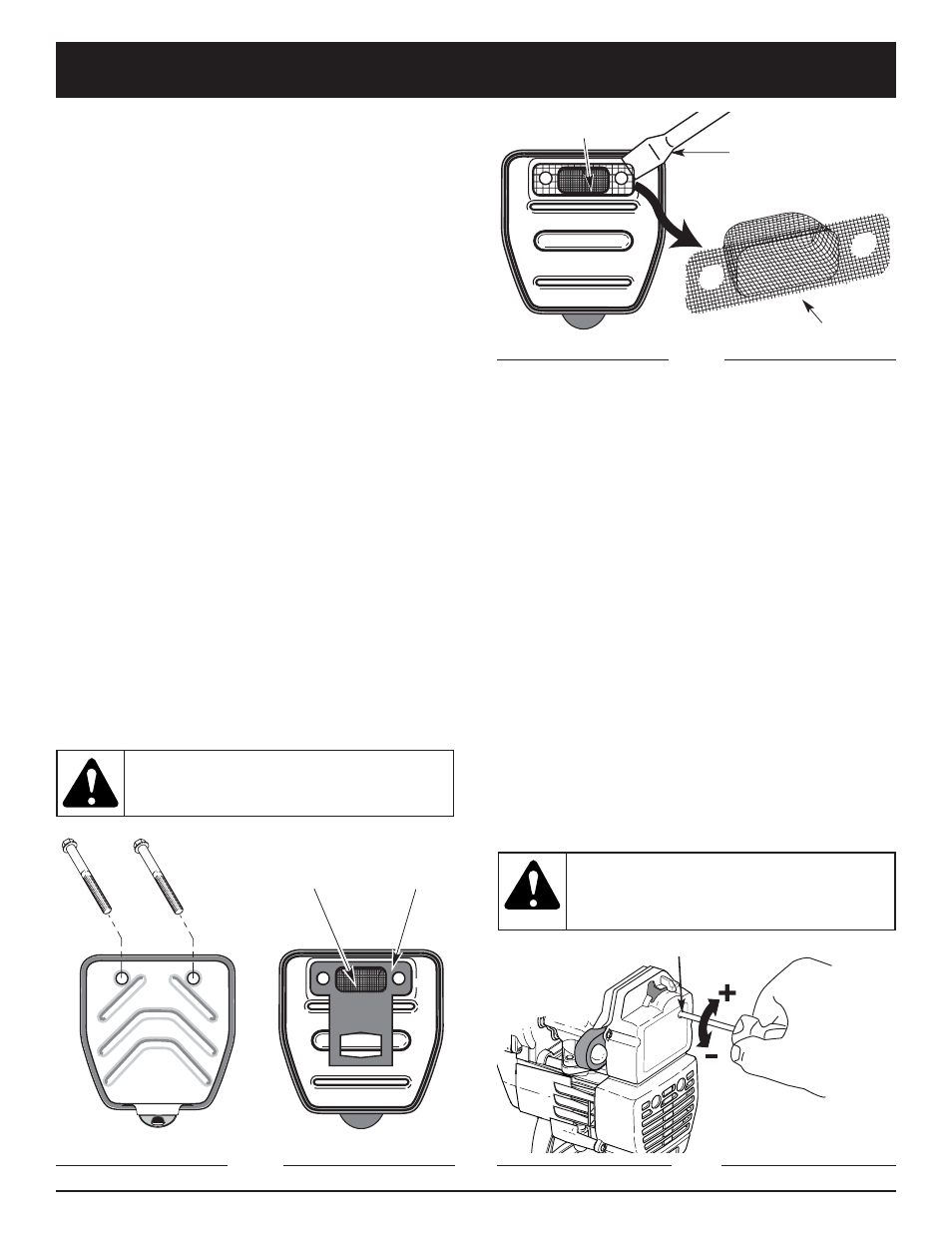

SPARK ARRESTOR MAINTENANCE

1. Remove air filter/muffler cover. Refer to Removing

the Air Filter/Muffler Cover.

2. Locate muffler front and the two (2) bolts securing it

to the engine (Fig. 26). Remove the two (2) bolts

using a flatblade screwdriver or 5/16-inch socket or

nut driver. Pull muffler off of the engine.

3. Turn muffler over to the back side and locate the

exhaust gasket. Remove the muffler gasket from the

muffler (Fig. 26).

NOTE: If the exhaust gasket is torn or damaged, replace

it with a new gasket before reassembling muffler.

4. Using a small flatblade screwdriver, carefully pry up

the spark arrestor from the recessed hole (Fig. 27).

Remove the spark arrestor from the muffler.

5. Clean the spark arrestor with a wire brush. Replace it

if it is damaged or if it is impossible to clean

thoroughly (Fig. 27).

6. Reinstall the spark arrestor by pressing it into the

recessed hole on the muffler's back side. Make sure

it fits tightly against the muffler and is not raised up.

7. Place the exhaust gasket against muffler's back side.

Align the gasket bolt holes with the bolt holes in the

muffler. While holding exhaust gasket in place, insert

the bolts into the muffler's front side (Fig. 26).

8. Place the muffler (with the exhaust gasket in place

and bolts inserted), against the engine, aligning the

bolt holes. Tighten the bolts to secure the muffler to

the engine.

If using a torque wrench, torque to:

80-90 in.•lb. (9-10.2 N•m)

9. Reinstall the air filter/muffler cover.

Fig. 27

Fig. 26

Muffler - Front Side

Muffler - Back Side

Bolts

Exhaust

Gasket

Spark

Arrestor

Muffler - Back Side

Spark Arrestor

Flatblade

Screwdriver

Spark Arrestor

WARNING: If the muffler is not tightened

securely, it could fall off causing damage to

the unit and possible serious personal injury

MAINTENANCE AND REPAIR INSTRUCTIONS

Check Petrol Mixture

Old and/or improperly mixed petrol is usually the reason

for improper unit performance. Drain and refill the tank

with fresh, properly-mixed petrol prior to making any

adjustments. Refer to Oil and Petrol Information.

Clean Air Filter

The condition of the air filter is important to the operation

of the unit. A dirty air filter will restrict air flow and

change the air/petrol mixture. This is often mistaken for

an out of adjustment carburetor. Check the condition of

the air filter before adjusting the idle speed screw. Refer

to Air Filter Maintenance.

Adjust Idle Speed Screw

If, after checking the petrol mixture and cleaning the air

filter, the engine still will not idle, adjust the idle speed

screw as follows:

1. Start the engine and let it run at a high idle for a

minute to warm up. Refer to Starting/Stopping

Instructions.

CARBURETOR ADJUSTMENT

The idle speed of the engine is adjustable through the air

filter/muffler cover (Fig. 28).

NOTE: Careless adjustments can seriously damage your

unit. An authorized service dealer should make

carburetor adjustments.

WARNING: The cutting attachment will spin

during idle speed adjustments. Wear

protective clothing and observe all safety

instructions to prevent serious personal injury.

Idle Speed Screw

Fig. 28