Adjustments, Warning – Ryobi OSS500 User Manual

Page 9

9

ADJUSTMENTS

WARNING:

The sander should never be connected to a power

supply when you are assembling parts, making ad-

justments, cleaning, or when not in use. Disconnect-

ing the tool will prevent accidental starting that could

cause serious personal injury.

SELECTING SANDING SLEEVES

Selecting the correct size diameter, correct size grit, and

correct type sanding sleeve is an extremely important

step in achieving a high quality sanded finish. Aluminum

oxide, silicon carbide, and other synthetic abrasives are

best for power sanding. Natural abrasives, such as flint

and garnet are too soft for power sanding.

In general, when sanding, coarse grit removes the most

material and fine grit produces the best finish. The

condition of the surface to be sanded determines which

grit will do the best job. If the surface is rough, start with

a coarse grit and sand until the surface is uniform. Then

use medium grit to remove scratches left by the coarser

grit. Finally, use finer grit for finishing the surface. Always

continue sanding with each grit until the surface is

uniform.

NOTE: Do not use the sander without a sanding sleeve.

Doing so will damage the rubber spindle.

Select and install the desired sanding sleeve for your

particular application. As mentioned previously, you can

use sanding sleeves from 1/2 in. (12.7 mm) to 3 in.

(76.2 mm) in diameter with this sander. Choose one that

is close in size to the workpiece you are sanding.

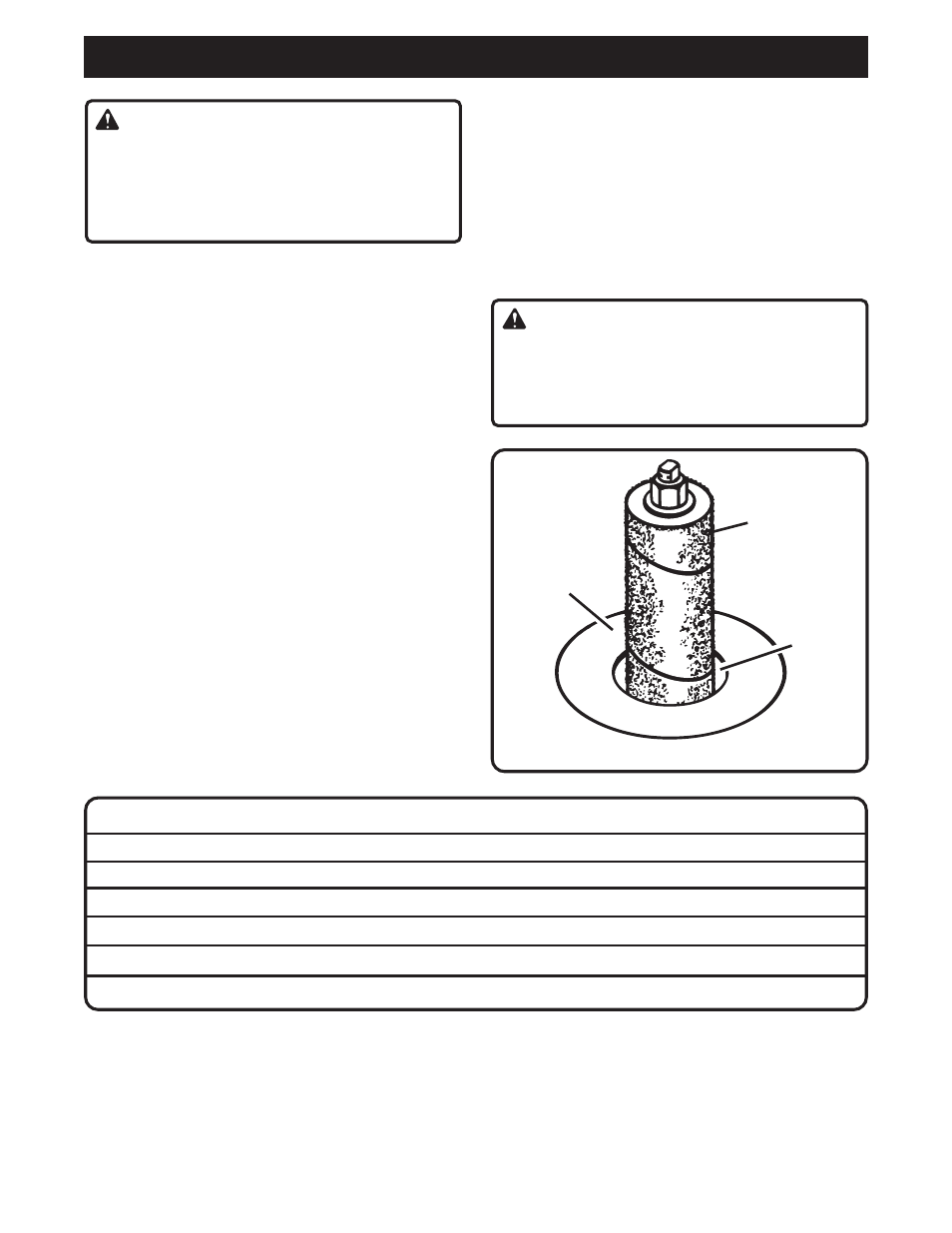

Fig. 2

SANDING

SLEEVE

THROAT

PLATE

THROAT

PLATE

OPENING

SELECTING THROAT PLATES/UPPER

SPINDLE WASHERS

See Figure 2.

Six throat plates are provided with this sander. Each

throat plate indicates the correct sanding sleeve/rubber

spindle size to use.

The chart below identifies the relationship between

sanding sleeves/rubber spindles, throat plates, and upper

spindle washers.

WARNING:

Failure to use the correct size throat plate with its

matching sanding sleeve could result in fingers being

pinched or the workpiece being pulled down between

the throat plate and the sanding sleeve.

Sanding Sleeve/Rubber Spindle

Throat Plate

Upper Spindle Washer

1/2 in. (12.7 mm)

.5” (13 mm)

5/8 in. (15.9 mm)

3/4 in. (19.1 mm)

.75” (19 mm)

7/8 in. (22.2 mm)

1 in. (25.4 mm)

1” (26 mm)

7/8 in. (22.2 mm)

1-1/2 in. (38.1 mm)

1.5” (38 mm)

7/8 in. (22.2 mm)

2 in. (50.8 mm)

2” (51 mm)

1-13/16 in. (46 mm)

3 in. (76.2 mm)

3” (76 mm)

1-13/16 in. (46 mm)