Installation, Gas connection, Gas pipe pressure testing – Regency F38-NG2 User Manual

Page 7

Regency F38-2 Freestanding Gas Heater

7

INSTALLATION

Flueing Requirements

A100 mm diameter fl ue is required. For cosmetic

or aesthetic purposes 6" outer fl ue can be used

as long as an approved inner fl ue is installed.

Fasten but do not penetrate the inner sleeve of

the fl ue when tightening the screw.

The minimum fl ue required is 3.3m from fl oor

level.

Follow all fl ueing manufacturer’s requirements

and local building codes or AS5601-2004.

GAS CONNECTION

The gas line should be rigid pipe. Copper may

also be used if approved by AS5601-2004.

The gas connection at the valve is 1/2 male.

For minimum and maximum supply pressure

see the System Data Table.

GAS PIPE PRESSURE

TESTING

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut-off valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig. (3.45

kPa). Disconnect piping from valve at pressures

over 3.45 kPa (14" w.c.).

The manifold pressure is controlled by a regulator

built into the gas control, and should be checked

at the pressure test point.

Note: To properly check gas pressure,

both inlet and manifold pressures

should be checked using the valve

pressure ports on the valve.

1) Make sure the valve is in the "OFF" posi-

tion.

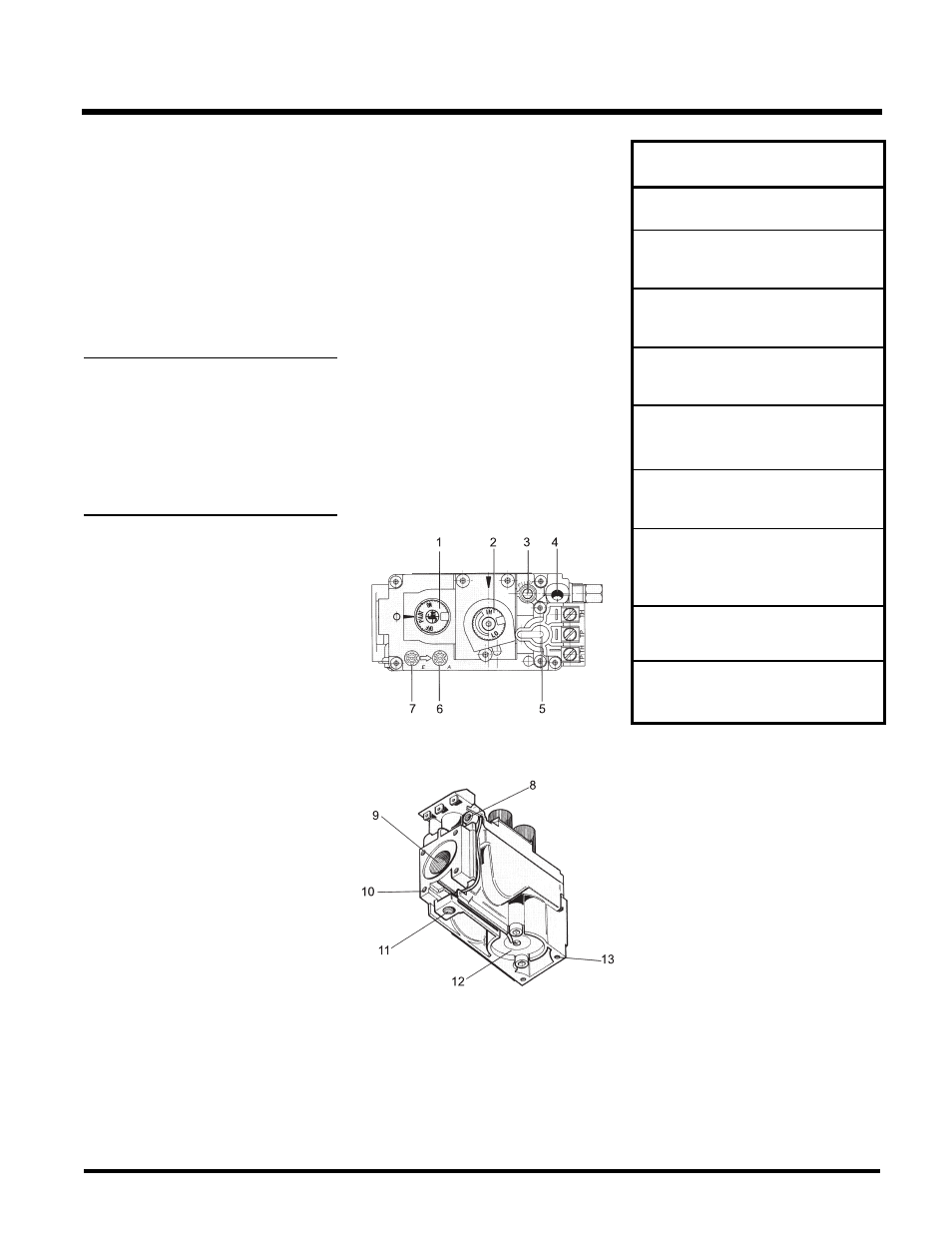

2) Loosen the "IN" (# 7) and/or "OUT" (# 6)

pressure tap(s), turning counterclockwise

with a 1/8" wide fl at screwdriver.

3) Attach manometer to "IN" and/or "OUT"

pressure tap(s) using a 5/16" ID hose.

4) Light the pilot and turn the valve to "ON"

position.

5) The pressure check should be carried out

with the unit burning and the setting should

be within the limits specifi ed on the safety

label.

6) When fi nished reading manometer, turn

off the gas valve, disconnect the hose and

tighten the screw (clockwise) with a 1/8" fl at

screwdriver. Screw should be snug, but do

not over tighten.

S.I.T. Valve Description

1) Gas on/off knob

2) Manual high/low adjustment

3) Pilot

Adjustment

4) Thermocouple

Connection

5) Main

Operator

6) Outlet Pressure Tap

7) Inlet

Pressure

Tap

8) Pilot

Outlet

9) Main Gas Outlet

10) Flange Securing Screw Holes

11) Alternative TC Connection Point

12) Thermoelectric Unit

13) Additional Valve Mounting Hole

F38-NG2: For 0 to 610 meters altitude

F38-LPG2: For 0 to 610 meters altitude

Burner Inlet Orifi ce Sizes:

NG

LPG

Burner

#33

#52

Max. Input

NG

38

mj

LPG

31

mj

Min. Input

NG

24.1

mj

LPG

24.5

mj

Supply Pressure

NG

1.74

kPa

LPG

2.99

kPa

Manifold Pressure

NG

0.87

kPa

LPG

2.65

kPa

Electrical: 240 V. 50Hz.

Circulation: High/Off/LO speed fan, 150/89

CFM.

Log Set: Ceramic fi ber, 7 per set.

Aeration Setting

NG Full

Open

LPG 6.4 mm

Flue Restrictor Setting

NG Full

Open

LPG Full

Open

System Data

F38-2