Operation – Ryobi RE601 User Manual

Page 15

Page 15

OPERATION

PROPER FEEDING

The right feed is neither too fast nor too slow. It is the rate at

which the bit is being advanced firmly to produce a continu-

ous spiral of uniform chips — without hogging into the wood

to make large individual chips or, on the other hand, to create

only sawdust. If you are making a small diameter, shallow

groove in soft, dry wood, the proper feed may be about as

fast as you can travel your router along your guide line. On

the other hand, if the bit is a large one, the cut is deep or the

wood is hard to cut, the proper feed may be a very slow one.

Then, again, a cross-grain cut may require a slower pace

than an identical with grain cut in the same workpiece.

There is no fixed rule. You will learn by experience from

practice and use. The best rate of feed is determined by

listening to the sound of the router motor and by feeling the

progress of each cut. Always test a cut on a scrap piece of

the workpiece wood, beforehand.

SPEED SELECTION

In general, if the material being cut is hard, the cutter size is

large, or the depth of cut is deep, then your router should be

run at slower speeds. When these situations exist, turn the

variable speed control selector until the desired speed is

reached.

See Figure 13.

NOTE: Carbide cutters cut at higher speeds than steel

cutters and should be used when cutting very hard materials.

Keep cutters sharp at all times.

FORCE FEEDING

Clean, smooth routing and edge shaping can be done only

when the bit is revolving at a relatively high speed and is

taking very small bites to produce tiny, cleanly severed

chips. If your router is forced to move forward too fast, the

RPM of the bit becomes slower than normal in relation to its

forward movement. As a result, the bit must take bigger bites

as it revolves. “Bigger bites” mean bigger chips, and a

rougher finish. Bigger chips also require more power, which

could result in the router motor becoming overloaded.

Under extreme force-feeding conditions the relative RPM of

the bit can become so slow — and the bites it has to take so

large — that chips will be partially knocked off (rather than

fully cut off), with resulting splintering and gouging of the

workpiece.

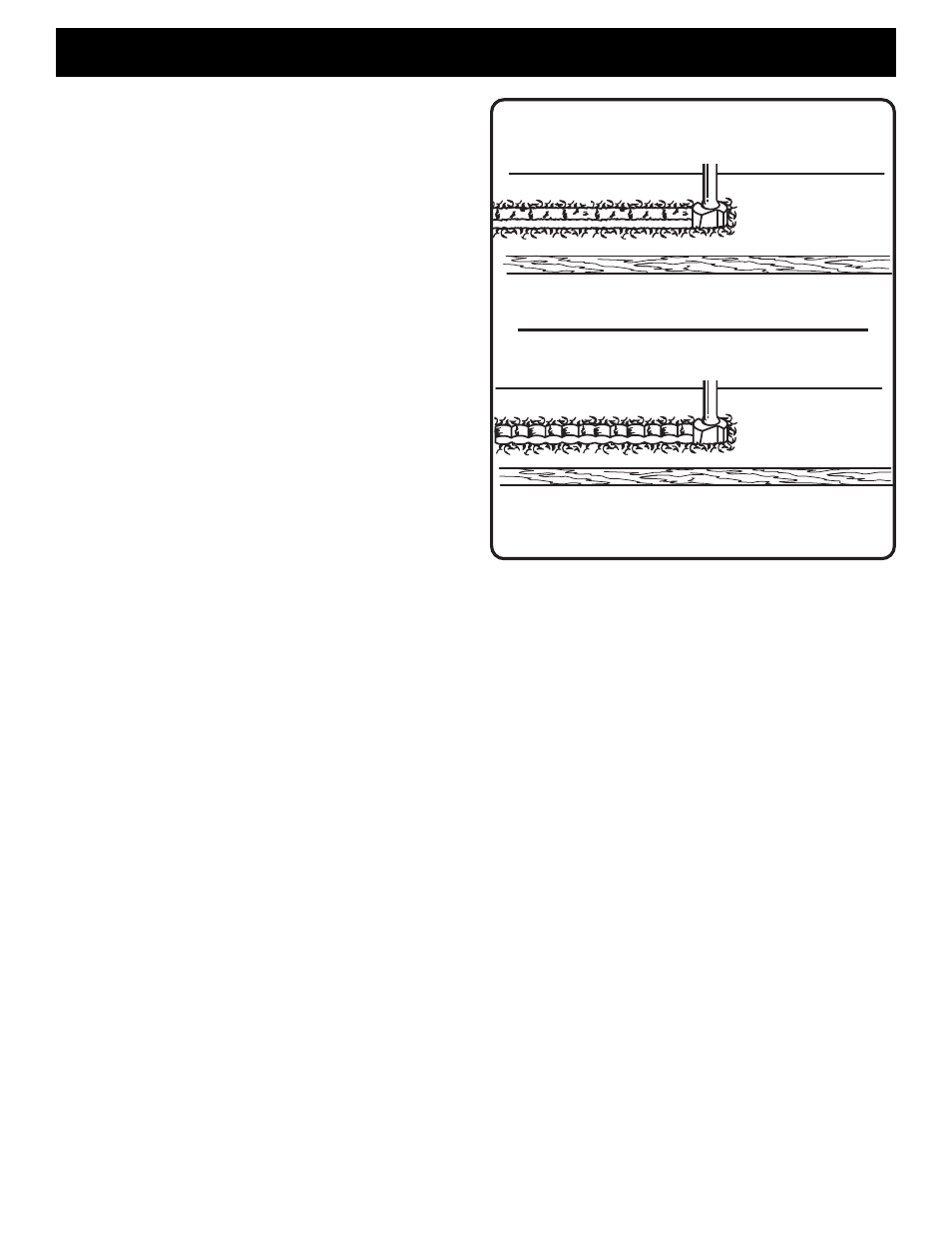

See Figure 15.

Your Ryobi router is an extremely high-speed tool (10,000 -

22,000 RPM no-load speed), and will make clean, smooth

cuts if allowed to run freely without the overload of a forced

(too fast) feed. Three things that cause “force feeding” are bit

size, depth-of-cut, and workpiece characteristics. The larger

the bit or the deeper the cut, the more slowly the router

should be advanced. If the wood is very hard, knotty, gummy

or damp, the operating pace must be slowed still more.

You can always detect “force feeding” by the sound of the

motor. Its high-pitched whine will sound lower and stronger

as it loses speed. Also, the strain of holding the tool will be

noticeably increased.

TOO FAST

TOO SLOW

Fig. 15

TOO SLOW FEEDING

It is possible to spoil a cut by moving the router forward too

slowly. When it is advanced into the work too slowly, a

revolving bit does not dig into new wood fast enough to take

a bite; instead, it simply scrapes away sawdust-like particles.

Scraping produces heat, which can glaze, burn, or mar the

cut. In extreme cases, it can even overheat the bit so as to

destroy its hardness.

In addition, it is more difficult to control a router when the bit

is scraping instead of cutting. With practically no load on the

motor the bit will be revolving at close to top RPM, and will

have a much greater than normal tendency to bounce off the

sides of the cut (especially, if the wood has a pronounced

grain with hard and soft areas). As a result, the cut produced

may have rippled, instead of straight sides.

See Figure 15.

“Too-slow feeding” can also cause your router to take off in

a wrong direction from the intended line of cut. Always

grasp and hold your router firmly with both hands when

routing.

You can detect “too-slow feeding” by the runaway too-highly

pitched sound of the motor; or by feeling the “wiggle” of the

bit in the cut.