Maintenance – Ryobi AG452 User Manual

Page 15

15

MAINTENANCE

GUARD REPLACEMENT

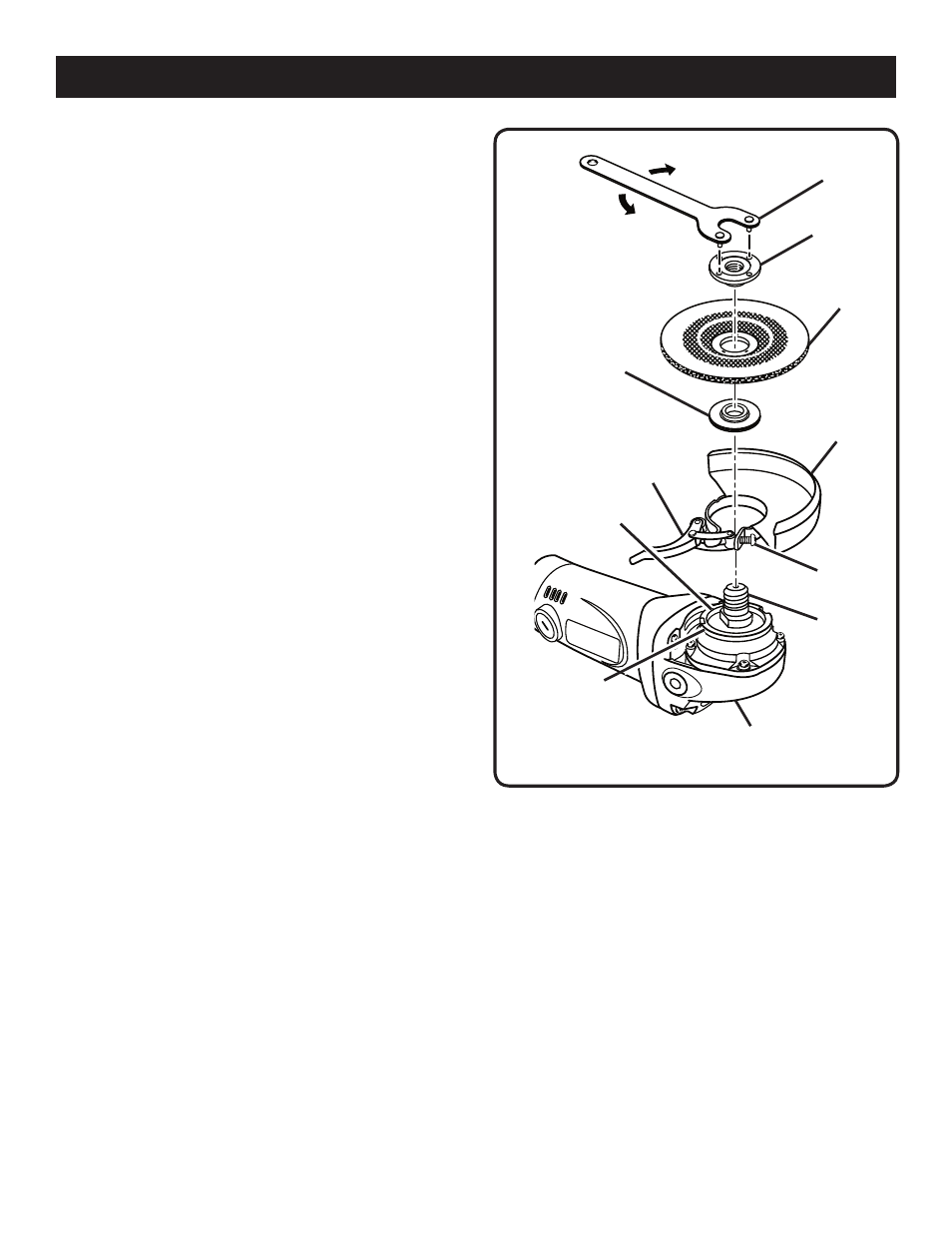

See Figure 13.

After extended use, the guard may become worn and need

adjustment or replacing. Or, if you drop the angle grinder and

damage the guard, it may be necessary to replace it.

To replace the guard:

Unplug the angle grinder.

Depress spin

dle lock button and rotate nut with provided

wrench until spindle locks.

Using the wrench provided, loosen and remove nut,

grinding or accessory wheel, and disc flange from spindle

if necessary.

NOTE: To prevent damage to the spindle or spindle lock,

always allow motor to come to a complete stop before

engaging spindle lock.

Unlock the guard clamp lever.

Remove the guard.

Place the new guard on the shoulder of the bearing cap,

aligning the arrow with the slot on the bottom of the angle

grinder.

NOTE: If the new guard will not fit, loosen the clamp

screw until it will slide over the bearing cap. Be sure the

tabs on the guard are seated in the groove in the bearing

cap.

Rotate guard to the correct position as shown in figures

9 and 10.

Lock the guard cl

amp lever.

Tighten clamp screw securely if needed.

WRENCH

FLANGE

NUT

GRINDING

WHEEL

GUARD

DISC

FLANGE

CLAMP

SCREW

TO

LOOSEN

TO

TIGHTEN

SPINDLE

LOCK BUTTON

SPINDLE

BEARING CAP

Fig. 13

ARROW

GUARD

CLAMP

LEVER