Maintenance and repair instructions – Ryobi 890R User Manual

Page 23

23

MAINTENANCE AND REPAIR INSTRUCTIONS

4. Disconnect the spark plug wire.

5. Clean dirt from around the spark plug. Remove the

spark plug from the cylinder head by turning a 5/8 in.

socket counterclockwise.

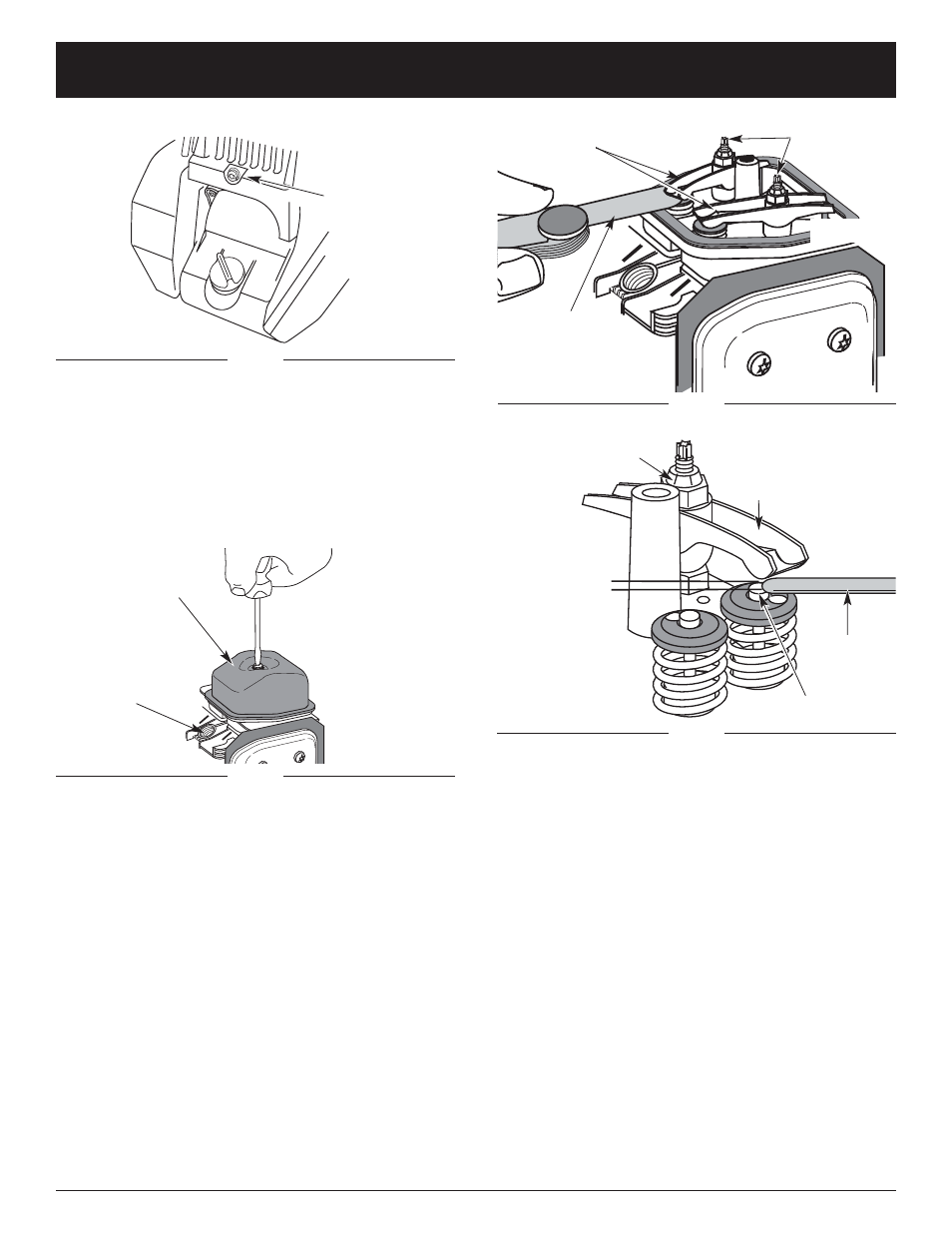

6. Remove the engine cover (Fig. 51).

7. Clean dirt from around the rocker arm cover.

Remove the screw holding the rocker arm cover with

a large flat blade screwdriver or Torx T-25 bit

(Fig. 53). Remove the rocker arm cover and gasket.

3. Remove the screw behind the engine cover (Fig. 52).

Rocker Arm Cover

Screw

Fig. 52

Fig. 53

Spark Plug Hole

8. Pull the starter rope slowly to bring the piston to the top

of its travel, (known as top dead center). Check that:

• The piston is at the top of its travel while looking in

the spark plug hole (Fig. 53)

• Both rocker arms move freely, and both valves are

closed

If these statements are not true, repeat this step.

9. Slide the feeler gauge between the rocker arm and

the valve return spring. Measure the clearance

between the valve stem and rocker arm (Fig. 54).

Measure both the intake and exhaust valves.

Adjusting Nuts

Feeler Gauge

Rocker Arms

Fig. 54

Fig. 55

10. If the clearance is not within specification:

a. Turn the adjusting nut using a 5/16 inch (8 mm)

wrench or nut driver (Fig. 55).

• To increase clearance, turn the adjusting nut

counterclockwise.

• To decrease clearance, turn the adjusting nut

clockwise.

b. Recheck both clearances, and adjust as necessary.

11. Reinstall the rocker arm cover using a new gasket.

Torque the screw to 20–30 in

•

lb (2.2–3.4 N

•

m).

12. Reinstall the engine cover. Check alignment of the

cover before tightening the screws. Tighten screws.

13. Reinstall the muffler cover. Slip the rear tab on the

muffler cover into the engine cover rear slot. Then

slide the remaining slots into the taps until they snap

into place (Fig. 50).

14. Check the spark plug and reinstall. See Replacing

the Spark Plug.

15. Replace the spark plug wire.

INTAKE

EXHAUST

The recommended clearance for both intake and

exhaust is .003 – .006 in. (.076 – 0.152 mm). Use a

standard automotive .005 in. (0.127 mm) feeler gauge.

The feeler gauge should slide between the rocker arm

and valve stem with a slight amount of resistance,

without binding. See Figure 54 and 55.

Feeler Gauge

Adjusting Nut

Rocker Arm

.003–.006 in.

(.076–.152 mm)

Valve Stem