Maintenance and repair instructions – Ryobi 155VP User Manual

Page 14

MAINTENANCE AND REPAIR INSTRUCTIONS

14

11. Install the bump head cover over the inner reel. Align

the tabs on the cover with the slots in the outer

spool and press the cover evenly down until it snaps

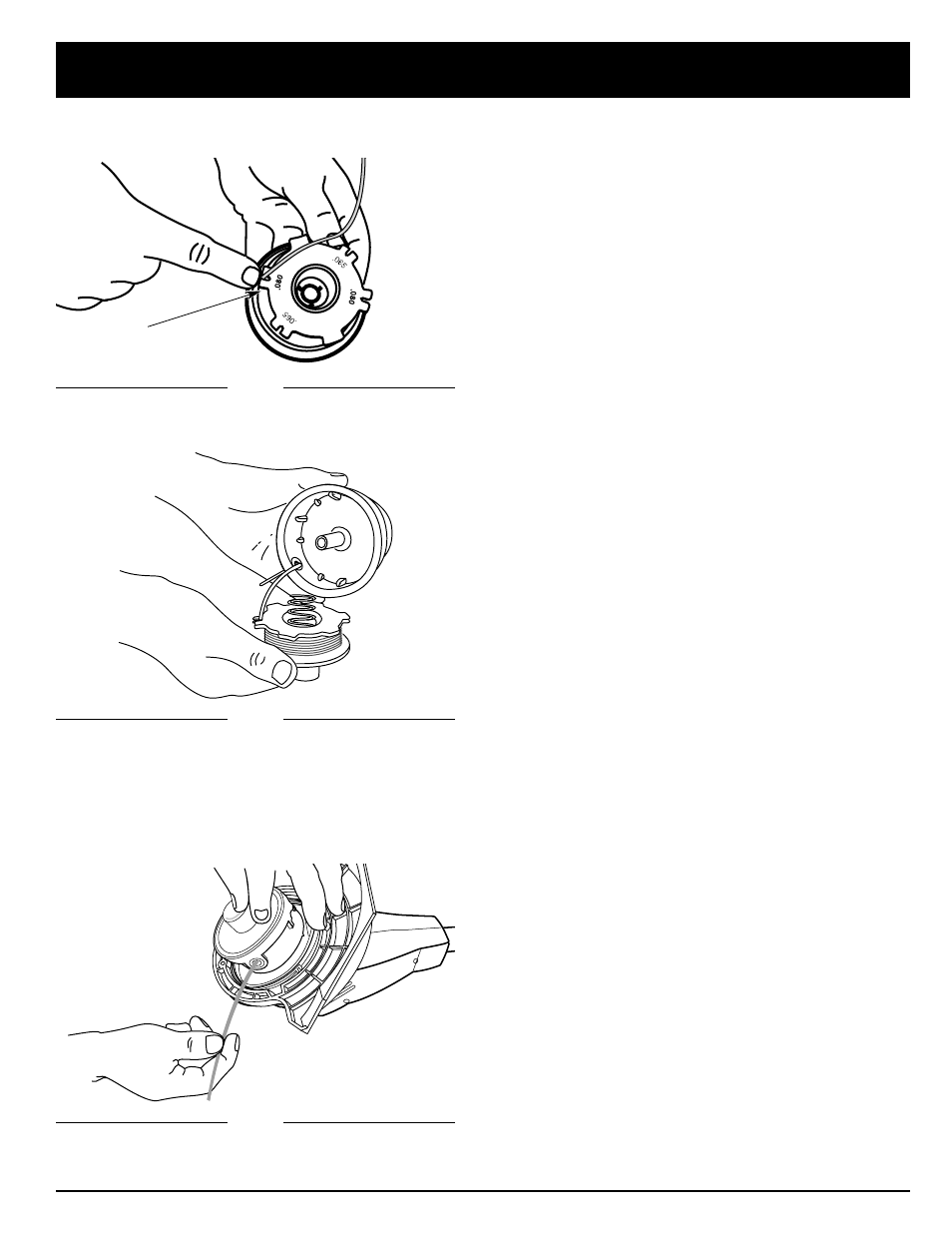

into place .

NOTE: Make sure the bump head cover tabs snap into

place or the inner reel will come out during

operation.

8. Insert the end of the line through the eyelet in the

outer spool (Fig. 22)

INSTALLING A PREWOUND REEL

Always use genuine replacement line. Using larger line

then the unit is designed for may make the motor

overheat or fail.

1. Remove the bump head cover by pressing in both

bump head cover tabs visible on either side of the

bump head outer spool (Fig. 18, Pg. 13).

NOTE: The spring will push the cover up when the tabs

release.

2. Remove the old inner reel and spring from the outer

spool (Fig. 18, Pg. 13).

3. Remove the spring from the old inner reel

(Fig. 18, Pg. 13).

4. Use a clean cloth to clean the inner surface of the

outer spool (Fig. 18, Pg. 13).

5. Insert the end of the line, on the prewound reel,

through the eyelet in the outer spool (Fig. 22)

6. Place inner reel and spring inside the outer spool.

NOTE: The spring must be assembled on the inner reel

before reassembling the bump head.

7. Hold the inner reel in place, grasp the line end and

pull firmly to release the line from the holding slot in

the inner reel (Fig. 23).

8. Install the bump head cover over the inner reel. Align

the tabs on the cover with the slots in the outer

spool and press the cover evenly down until it snaps

into place.

NOTE: Make sure the bump head cover tabs snap into

place or the inner reel will come out during

operation.

9. Place inner reel and spring inside the outer spool.

NOTE: The spring must be assembled on the inner reel

before reassembling the bump head.

10. Hold the inner reel in place, grasp the line end and

pull firmly to release the line from the holding slot in

the inner reel (Fig. 23).

Fig. 22

Fig. 23

7. Insert the end of the line into one of the two 0.80

holding slots (Fig. 21).

Fig. 21

0.80

Holding

Slot