Northern Industrial Tools 1961202 User Manual

Page 4

pressure of 90 PSI.

3. Check the air connection for leaks.

4. Disconnect from the air hose until next instructed to reconnect.

Note: Turn off your air compressor and disconnect the air hose when you are changing sockets.

After you attach the socket (not included), attach the air hose and turn the air compressor on.

ii.

Select the appropriate size 1/2" socket for your needs.

iii.

Push and snap the socket onto the anvil.

iv. Tightening

The max. working torque of the impact wrench is 300ft.-lbs. It can be adjusted from 115

ft.-lbs. to 300ft.-lbs. Make sure that the nut or bolt you are using the tool to tighten can

withstand the rated torque.

1. Tighten the nut as far as you can by hand.

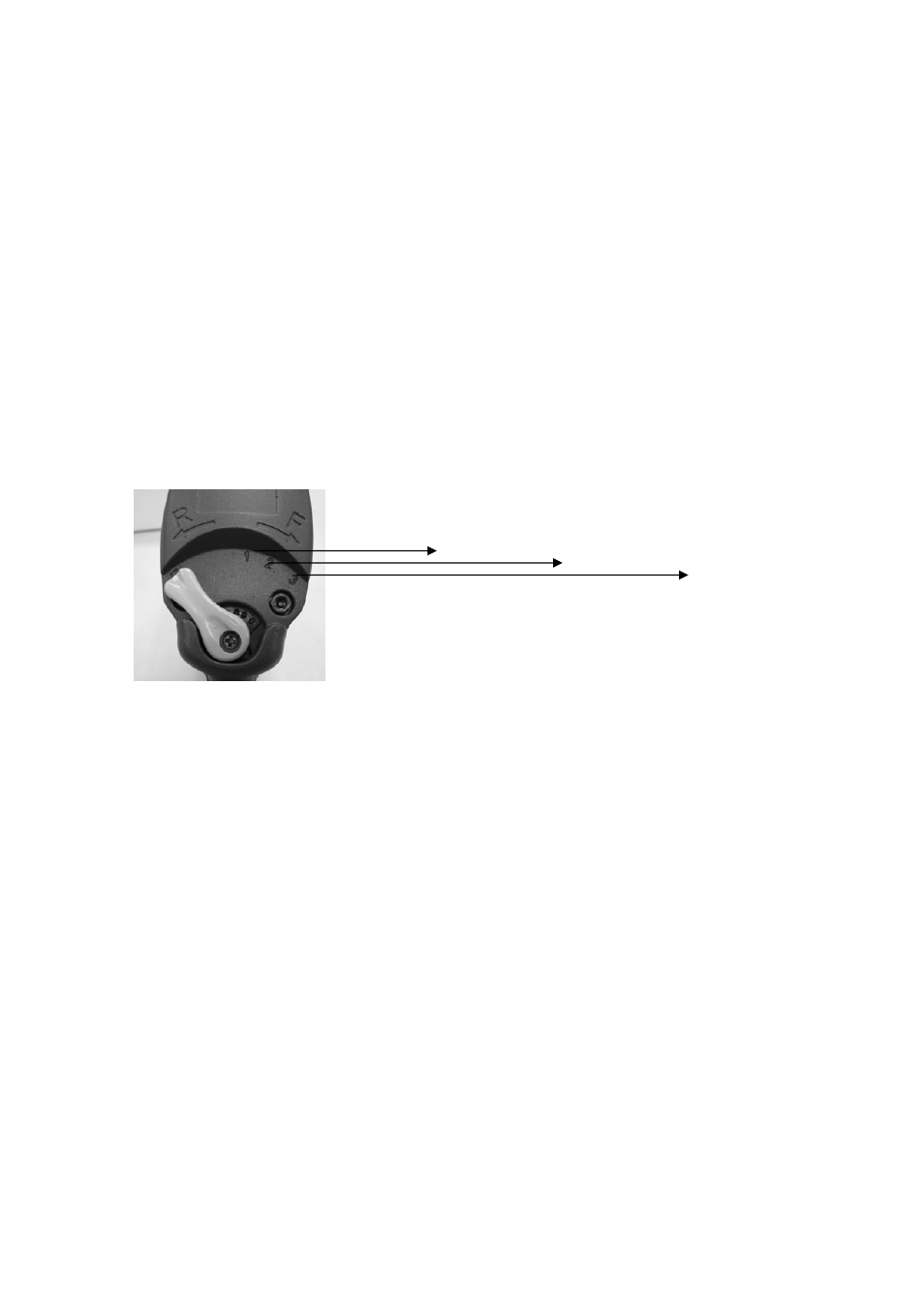

2. Place the socket on the nut. Press the REVERSE BUTTON (#30) to FORWARD 1, 2, 3.

You can get the different torque on different steps. (See Fig. 2)

FIG. 2

115 ft.-lbs.

190 ft.-lbs.

300 ft.-lbs.

3. Press the trigger to start the tool.

NOTE: When changing the step, stop pressing the trigger (#9), then adjust the reverse

button (#30).

NOTE:

¾ If the tool stalls while tightening, DO NOT raise the outlet pressure of the air compressor

above 90 PSI.

¾ When the nut has been tightened, remove the tool and socket. Do not overtighten.

¾ If available, check the recommended torque specifications for the nut. You should use a

torque wrench to torque the nut after using the impact wrench.

v. Loosening

1. Attach the correct size socket to the anvil.

2. Set the compressor’s pressure regulator to 90 PSI. Do not set the compressor’s outlet

regulator above 90 PSI.

3. Connect the tool to the air compressor’s hose. If a leak is detected, disconnect the air hose

and fix it before use.

4. Place the socket over the nut to loosen.

5. Grip the tool firmly. Press the REVERSE BUTTON (#30) to REVERSE step. Press the

trigger to start the tool.

(Caution: Make sure the nut or bolt can withstand the impact wrench’s working torque.)

Page: 4 of 7