Maintenance, Scheduled maintenance table – Nilfisk-Advance America RS 1300 User Manual

Page 55

INSTRUCTIONS FOR USE

ENGLISH

RS 1300

33015124(3)2008-02

33

MAINTENANCE

The lifespan of the machine and its maximum operating safety are ensured by correct and regular maintenance.

The following table provides the scheduled maintenance. The intervals shown may vary according to particular working conditions,

which are to be defi ned by the person in charge of the maintenance.

WARNING!

Maintenance procedures must be performed when the machine is off (ignition key removed).

Moreover, read carefully the instructions in Safety chapter before performing any maintenance procedure.

All scheduled or extraordinary maintenance procedures must be performed by qualifi ed personnel, or by an authorised Service

Center.

This Manual contains the Scheduled Maintenance Table and describes only the easiest and most common maintenance

procedures.

For other maintenance procedures contained in the Scheduled Maintenance Table or for extraordinary maintenance procedures see

the Service Manual that can be consulted at any Service Center.

For scheduled and extraordinary maintenance of the following optional equipments, refer to the relevant Manuals:

Salt spreader

Snow brush

Snow cutter

Camera kit

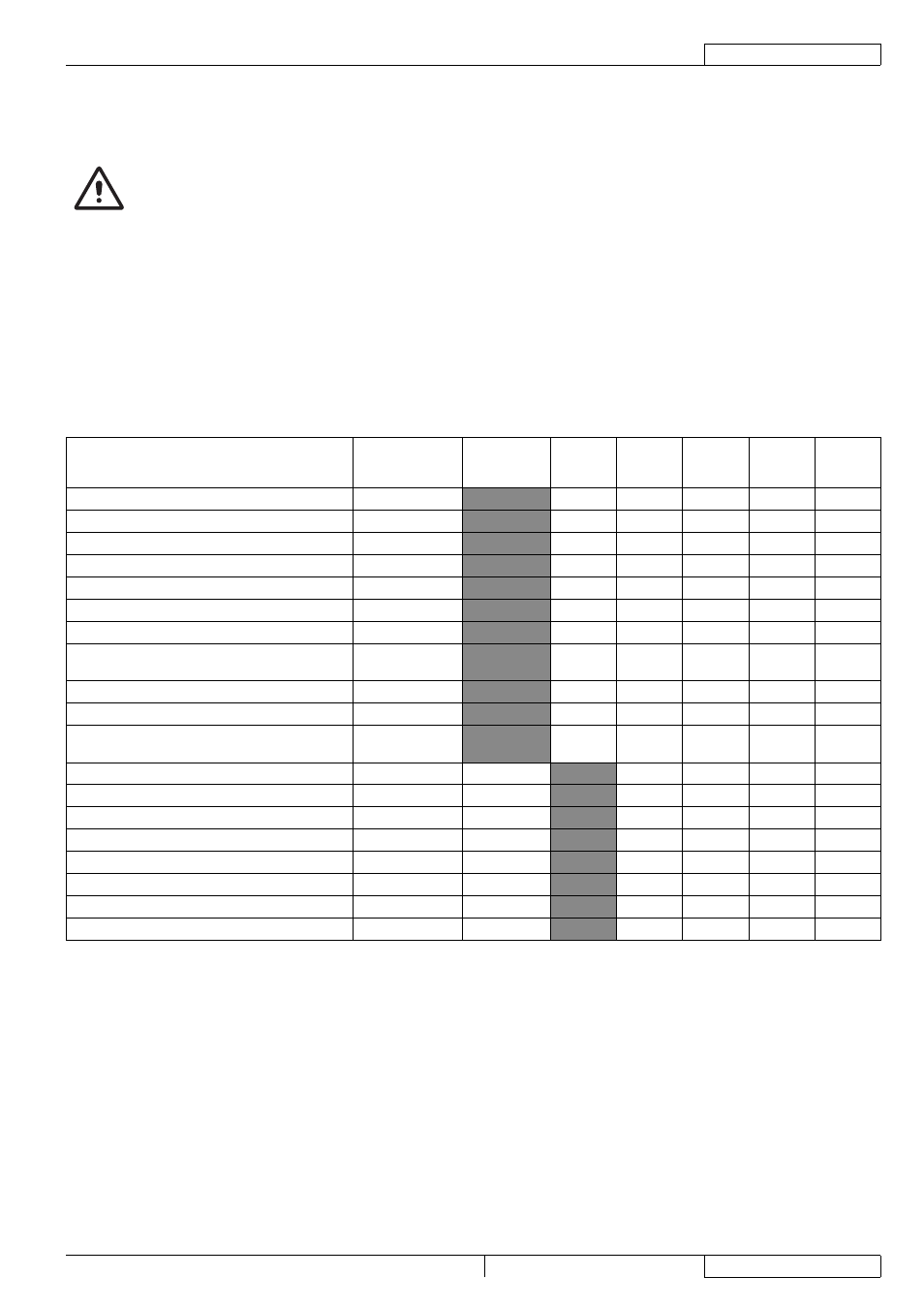

SCHEDULED MAINTENANCE TABLE

Maintenance

Running-in

period (after the

fi rst 50 hours)

Every 10

hours or

before use

Every

150

hours

Every

300

hours

Every

500

hours

Every

1,000

hours

Every

2,000

hours

Engine oil level check

Hydraulic system oil level check

Engine air pre-fi lter and fi lter cleaning

Engine radiator fi n cleaning check

Engine coolant level check

Hydraulic system oil cooler fi n check

Battery fl uid level check

Hopper, fi lter and suction hose cleaning, gasket

check and fan bearing lubrication

Water nozzle and fi lter cleaning

Brake fl uid level check

Reverse gear buzzer operation check and sensor

adjustment

Diesel engine start-up safety system check

(8)

Engine fuel fi lter cleaning

(1)

Engine radiator fi n cleaning

(1) (8)

Tire pressure check

Suction inlet and skirt height and operation check

Side broom position check and adjustment

3rd broom position check and adjustment

Hopper and suction hose gasket wear check

(8)

–

–

–

–