Nail plate installation, Tubing installation – NuTone CV352 User Manual

Page 5

5

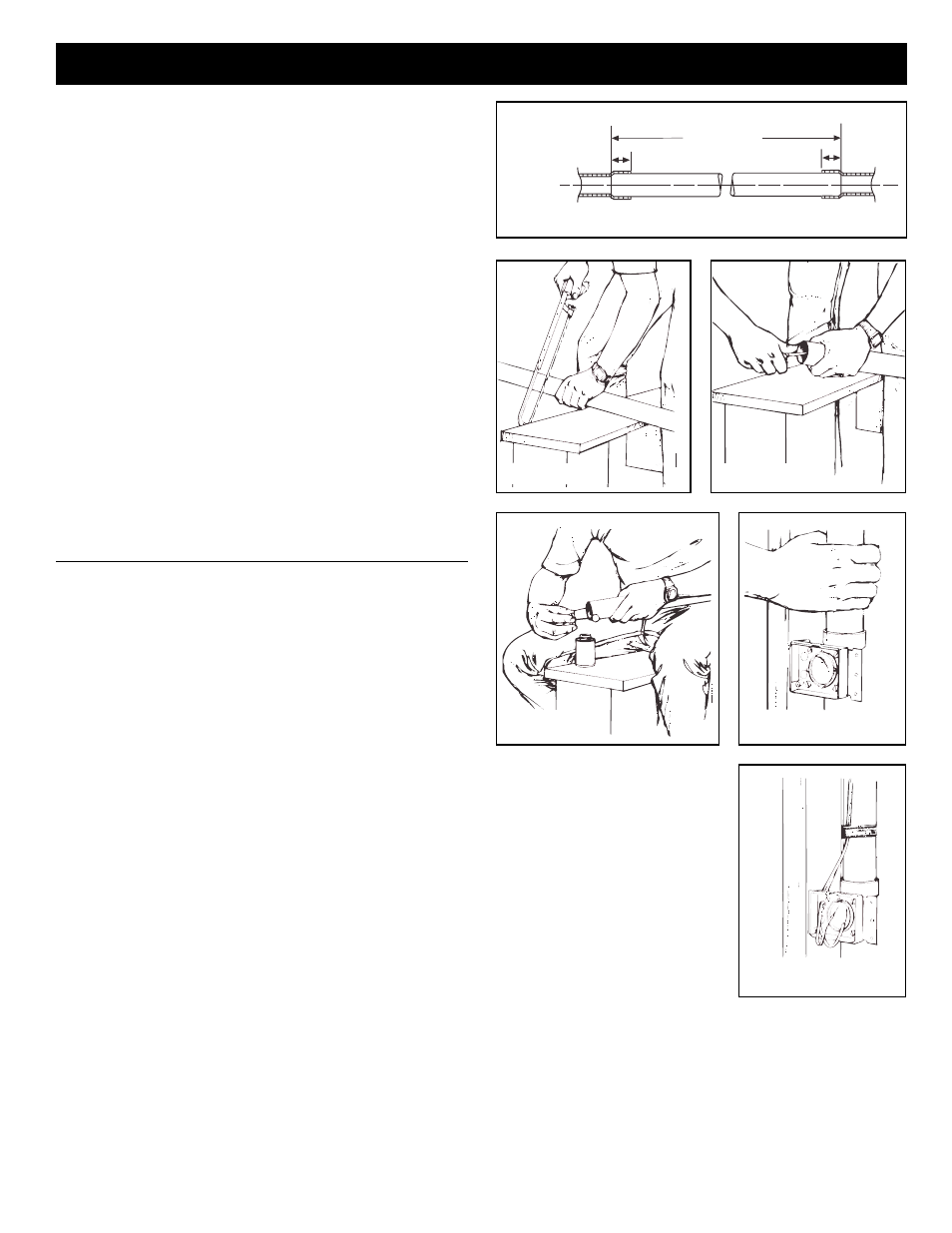

FIGURE 7

INCLUDE FITTING

RECESS IN

MEASUREMENT

TUBING MEASUREMENT

PVC TUBING

FIT TING

FIT TING

3

/

4

"

3

/

4

"

FIGURE 8

FIGURE 9

FIGURE 10

FIGURE 11

FIGURE 12

TUBING INSTALLATION

1. Cut a 2

1

⁄

2

" diameter hole in sole plate, header or stud directly

in line with opening of inlet bracket fitting. Note Figures 6

and 4 for center line dimensions.

2. Refer to Figure 7. Measure length of tubing needed to

connect inlet to trunk line. Allow approximately

3

⁄

4

" of tubing

for inserting into fittings.

3. Refer to Figure 8. Cut tubing, keeping cut square.

4. Refer to Figure 9. Remove burrs from both inside and

outside of tubing.

5. Before cementing, pre-assemble section to inlet fitting, check

for proper length.

6. Refer to Figure 10. Apply cement (Model 379) to outside of

tubing. Coat tubing approximately 1" back. Take care to keep

cement from inside of tube.

7. Refer to Figure 11. Insert tubing into fitting with a twisting

motion to evenly spread cement. Be sure tubing is firmly

seated in fitting.

8. If fittings have been attached to tubing at the end opposite the

inlet bracket, be sure alignment is proper before cement sets.

9. Refer to Figure 12. Low voltage wiring (Model 376) should

be completed as tubing is installed. Tape wire to tubing to

hold in place and insert through hole in inlet bracket.

NAIL PLATE INSTALLATION

Caution: When tubing is run through the wall stud, sole

plate, headers - or anywhere that building materials will be

attached - place a nail plate (Model 378) over that area

(on both sides if necessary) to prevent nails from piercing

tubing.