North Star 5000 PG User Manual

Page 7

6

STARTING ELECTRIC MOTORS

Electric motors require much more current (amps)

to start than to run. Some motors, particularly low cost

split-phase motors, are very hard to start and require 5

to 7 times more current to start than to run. Capacitor

motors are easier to start and usually require 2 to 4

times as much current to start than to run. Repulsion

Induction motors are the easiest to start and require

1.5 to 2.5 times as much to start than to run.

Most fractional motors take about the same

amount of current to run them whether they are of

Repulsion-Induction (RI), Capacitor (Cap), or Split-

Phase (SP) type. The following chart shows the

approximate current required to start and run various

types and sizes of 120 volt 60 cycle electric motors

under various conditions.

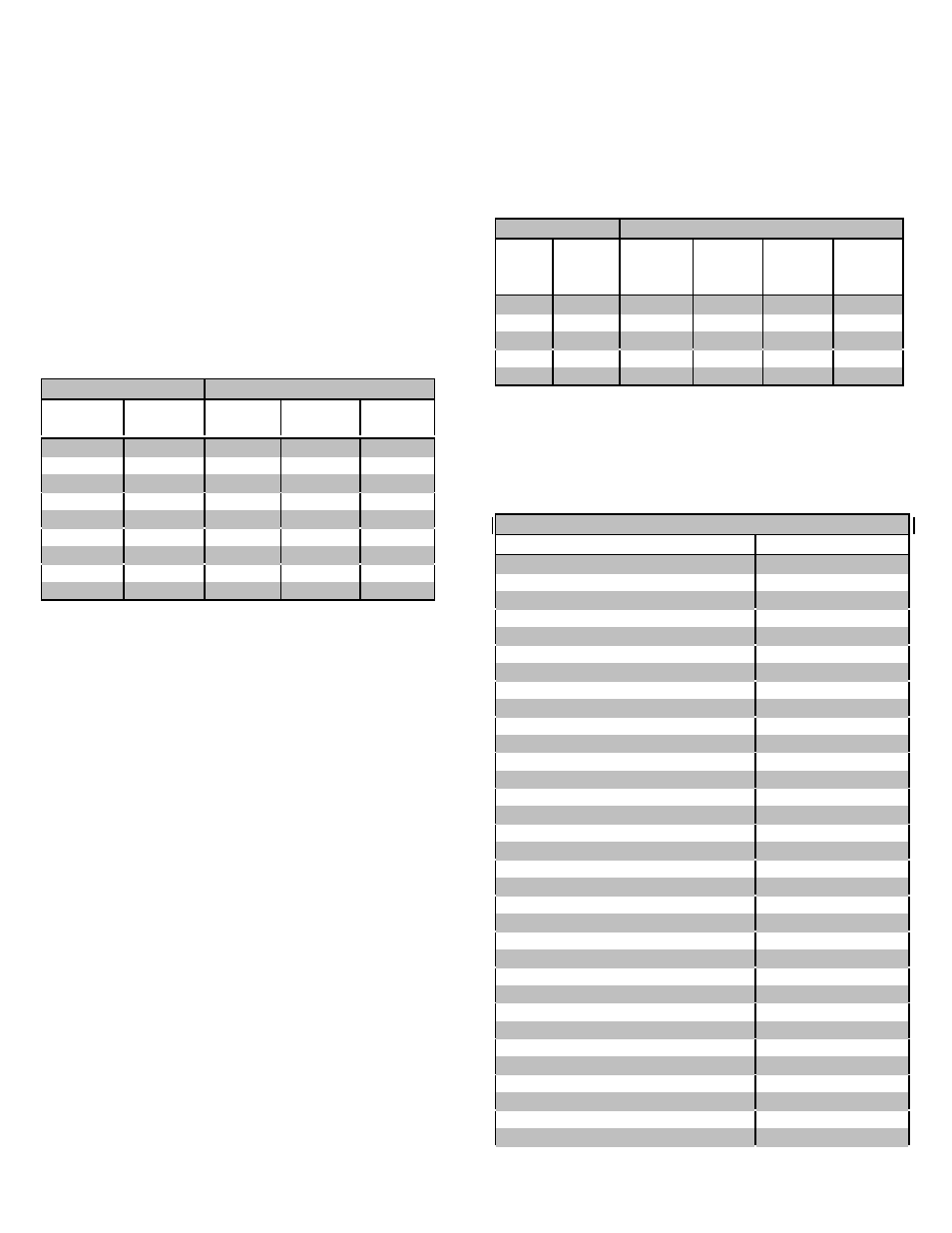

120V, 60 Hz Motors

Starting Amps

Hp motor

Running

Watts

RI type

Cap type

SP type

1/6

525

7-11

9-18

16-22

1/4

700

9-15

12-23

22-32

1/3

875

11-18

14-29

26-35

1/2

1175

15-25

20-40

NA

1

1925

24-40

32-64

NA

1 1/2

2400

30-50

40-80

NA

2

2900

36-60

48-96

NA

3

4075

51-85

68-136

NA

5

6750

84-140

112-224

NA

The figures given above are for an average load

such as a blower or fan. If the electric motor is

connected to a hard starting load such as an air

compressor, it will require more starting current. If it is

connected to a light load or no load such as a power

saw, it will require less starting current. The exact

requirement will also vary with the brand or design of

the motor.

Generators respond to severe overloading

differently than the power line. When overloaded, the

engine is not able to supply enough power to bring the

electric motor up to operating speed. The generator

responds to the high initial starting current, but the

engine speed drops sharply. The overload may stall

the engine. If allowed to operate at very low speeds,

the electric motor starting winding will burn out in a

short time. The generator winding might also be

damaged.

Running the generator under these conditions may

result in damage to the generator stator as well as the

motor windings. Because the heavy surge of current

is required for only an instant, the generator will not be

damaged if it can bring the motor up to speed in a few

seconds. If difficulties in starting a motor are

experienced, turn off all other electrical loads and if

possible reduce the load on the electric motor.

EXTENSION CORDS

When electric power is to be provided to various

loads at some distance from the generator, extension

cords can be used. These cords should be sized to

allow for distance in length and amperage so that the

voltage drop between the set and point of use is held

to a minimum.

Current/Pow er

Maximum Extension Cord Length

Amps

at

240V

Load

(watts)

#10

Ga.

Cord

#12

Ga.

Cord

#14

Ga.

Cord

#16

Ga.

Cord

10

2400

250’

150’

100’

75’

20

4800

125’

75’

50’

25’

30

7200

60’

35’

25’

10’

40

9600

30’

15’

10’

*

50

12000

15’

*

*

*

*Not recommended

CAUTION: Equipment damage can result from the

low voltage caused by using an extension cord with a

small wire size.

Use this chart to estimate the total load on your

generator.

For Determining Generator Load Requirements

Dev ice

Running Watts

Air Conditioner (12,000 Btu)

1700 (a)

Battery Charger (20 Amp)

500

Belt Sander (3”)

1000

Chain Saw

1200

Circular Saw (6-1/2”)

900

Coffee Maker

1000

Compressor (1 HP)

2000 (a)

Compressor (3/4 HP)

1800 (a)

Compressor (1/2 HP)

1400 (a)

Curling Iron

700

Dishwasher

1200

Edge Trimmer

500

Electric Nail Gun

1200

Electric Range (one element)

1500

Electric Skillet

1250

Furnace Fan (1/3 HP)

1200 (a)

Freezer

800 (b)

Hair Dryer

1200

Hand Drill (1”)

1100

Hand Drill (1/2”)

875

Hand Drill (3/8”)

500

Hand Drill (1/4”)

250

Hedge Trimmer

450

Home Computer

150

Impact Wrench

500

Jet Pump

800 (a)

Lawn Mower

1200

Light Bulb

100

Microwave Oven

700

Milk Cooler

1100 (a)

Oil Burner on Furnace

300

Oil Fired Space Htr (140,000 Btu)

400

Oil Fired Space Htr (85,000 Btu)

225