NHT 6.2 Ci User Manual

Page 4

Installation: New Construction (unfinished walls)

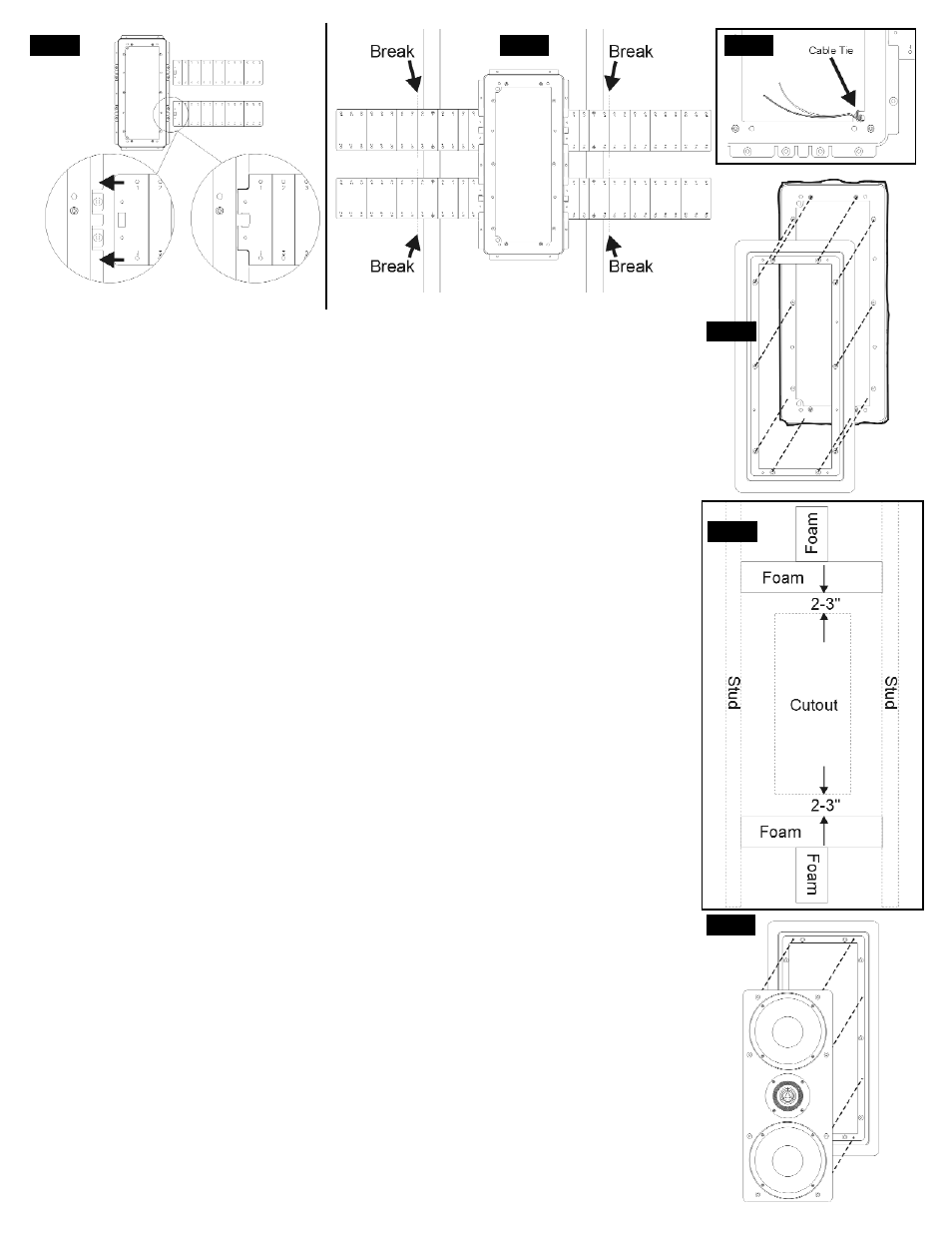

1. Begin by installing the mounting bracket between adjacent studs. The 6.2 Ci performs best

in the vertical orientation. The mounting bracket will not fit horizontally between studs with

16" centers. Attach the mounting wings to the bracket by inserting them into the locking plas-

tic tabs in the side of the bracket (fig.2).

2. Select the desired location for the speaker, using a level to ensure that it is precisely

positioned. The wings feature progressively elongated sections (1", 1", 2", 2", 2", 3", 3") with

screw holes spaced in one-inch increments. Attach the wings to the studs with screws or

staples. Break off the extra portion of the wing by bending it at one of the pre-stamped

"break" lines (fig.3).

3. Complete the pre-wiring before the drywall goes up (see "Tech Tips: Pre-Wiring for New

Construction"). Leave an extra few feet of speaker cable, and secure it to the cable tie on the

mounting bracket (fig.4).

4. During the drywall phase, cut a hole 19-3/4" high by 8-7/8" wide around the bracket. The

bezel outer frame will extend out about 1 inch beyond the perimeter of the cutout to hide

minor imperfections in the cutout.

5. After the drywall is complete, attach the bezel to the bracket with ten 4 x XXmm flathead

screws that line up with the ten raised bosses on the bracket (fig.5). Tighten screws snugly,

making sure not to over-tighten, as this may compromise the fit of the bezel. The use of

power screwdrivers is not recommended. The absorptive strip on the back of the bezel's

outer frame reduces unwanted vibrations and will compress slightly to allow the frame to rest

flush against the wall on all four sides. When installed correctly, the bracket and bezel

"sandwich" the drywall.

6. If the 6.2 Ci bezel frame and grille are to be painted in the wall, paint now before installing

the baffle (see "Painting").

7. Insert one of the 4" x 4" x 8" foam blocks vertically through the speaker cutout (fig. 6). Push

this block down approximately 7" below the edge of the cutout. Insert the second 4" x 4" x 8"

foam block and push up approximately 7" above the top edge of the speaker cutout. Bend

one of the 4" x 4" x 16" foam blocks into a U shape and push down into wall horizontally so

that it is 3" below the speaker cutout. Make sure that there is a good seal with the edge of

the foam and both the left and right wall studs. Repeat for the upper 4" x 4" x 16" foam block.

The foam should also make a good seal around the speaker wires. Add a 26" long piece of

unbacked R19 fiberglass insulation to the enclosure. (Be sure to wear protective gloves and

goggles when handling fiberglass to avoid contact with the fiber). You may need to cut a 7"

wide by 5" high rectangular hole in the center of the piece of fiberglass to make room for the

crossover on the back of the baffle.

8. Connect the speaker cable to the spring posts on the 6.2 Ci baffle, making sure to observe

correct polarity (see "Connections").

9. Attach the baffle to the bezel with eight 4 x yymm screws that line up with the eight holes

in the bezel (fig.7). Exercise caution not to damage the drivers. Tighten screws snugly,

making sure not to over-tighten, as this may compromise the fit of the baffle. The use of

power screwdrivers is not recommended.

10. Attach the metal grille by inserting it into the bezel.

fig.5

fig.7

fig.6

fig.3

fig.2

fig.4