Stove installation – Napoleon Fireplaces EPA 1100 User Manual

Page 5

5

W415-0512 / B / 11.15.05

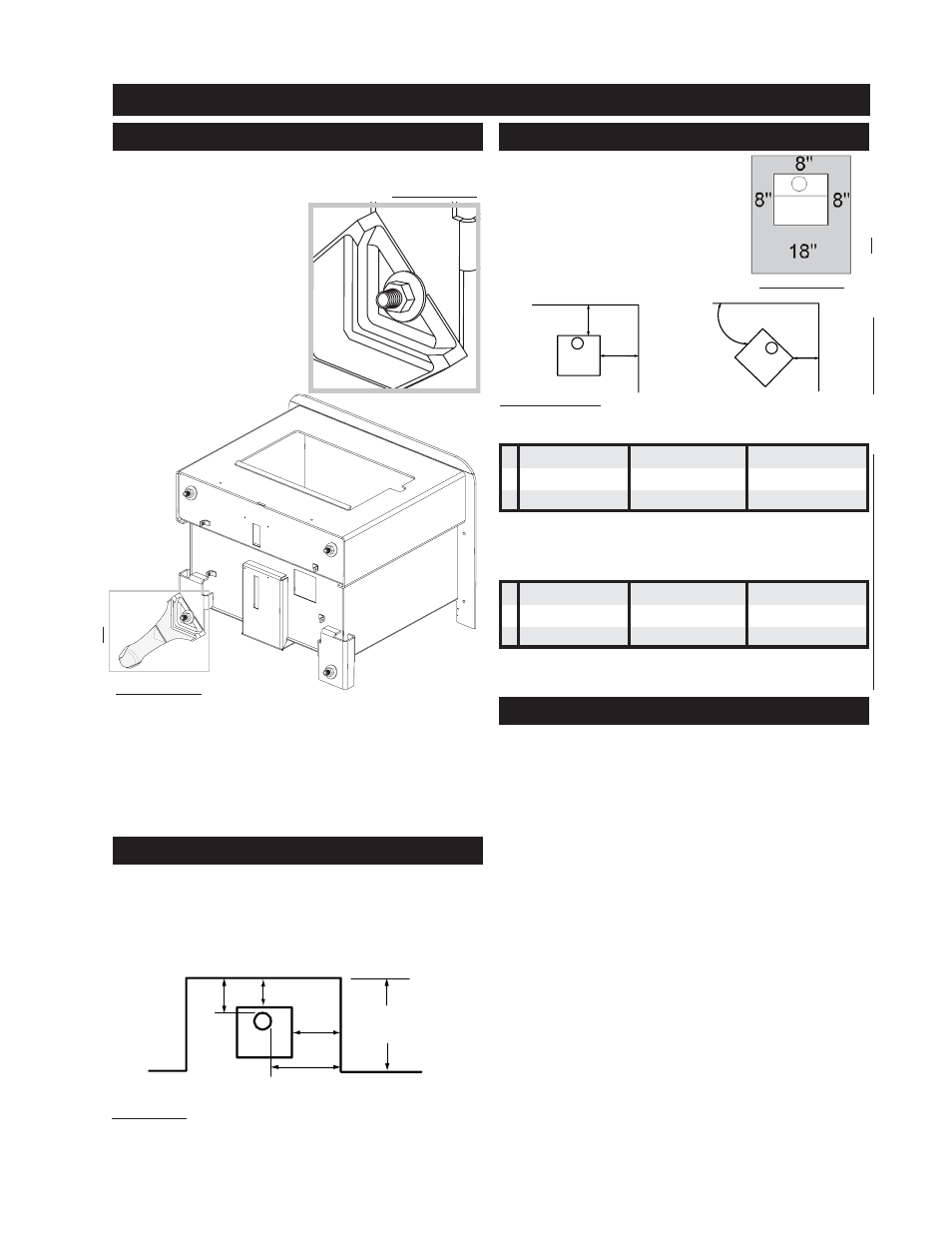

To avoid being damaged during shipping, the stove has

been bolted to the pallet and must be unbolted before the

stove can be installed.

1. Remove the 4 nuts and

washers from the underside of

the pallet.

2. Lift the stove up and away

from the pallet to clear the

threaded studs sticking

through the pallet. Place the

stove on its back onto a pro-

tective surface such as a car-

pet or blanket to avoid

scratches during leg installa-

tion.

3. Remove the four additional nuts from each of the four

studs.

4. Use four of the nuts and washers removed above to

install the legs as illustrated in FIGURES 2a & 2b.

5. Lift the stove up and gently set down on all four legs. Do

not pivot unit up on its legs, as this could result in damage

to the legs.

Model 1100 only may be installed, using a listed double

wall connector, such as Security DL6 in Canada, the

Simpson Duravent Plus DVL in the USA or an equivalent

double wall connector, into an alcove having a depth of no

more than 4 feet and a height of at least 7 feet. The mini-

mum clearances are as shown in FIGURE 3.

If the stove is to be installed on a

combustible floor, it must be placed

on an approved non-combustible

hearth pad, that extends 8" (200mm)

beyond the stove sides and back,

and 18" (455mm) to the front.

SINGLE WALL CHIMNEY CONNECTOR*

DOUBLE WALL CHIMNEY CONNECTOR

A 6” diameter single wall stove pipe, used to connect the

stove to the chimney, must be installed with the crimped

end toward the stove. This will ensure that the moisture

which condenses from the burning wood will flow back into

the fire chamber. Each joint in the stove pipe must be se-

cured with at least three sheet metal screws.

This room heater must be connected to:

1) A chimney complying with the requirements for Type HT

chimneys in the Standard for Chimneys, Factory-Built, Resi-

dential Type and Building Heating Appliance UL 103, or

2) A code-approved masonry chimney with a flue liner.

Vent the stove into a masonry chimney or an approved,

insulated solid-fuel stainless-steel chimney with as short

and straight a length of six-inch (150mm) diameter smoke

pipe as possible. Connection to a masonry chimney must

be by a metal or masonry thimble cemented in place.

An insulated stainless steel chimney must be supported

at the ceiling or roof and its installation must comply with

its manufacturer's instructions.

FIGURE 2B

FIGURE 3

9"

6"

14"

23"

ALCOVE

4 FOOT

MAX.

1100/1100L/1150 1400/1400L

1900

A

12" (305mm)

12" (305mm)

22" (560mm)

B

10" (254mm)

12" (305mm)

12" (305mm)

C

6" (152mm)

6" (152mm)

8" (205mm)

*

CLEARANCES CAN BE REDUCED WITH SHIELDING ACCEPTABLE TO LOCAL

AUTHORITIES. REDUCED INSTALLATION MUST COMPY WITH NFPA 211 or

CAN/CSA-B365.

STOVE INSTALLATION

INSTALLING THE LEGS

STOVE INSTALLATION

CHIMNEY CONNECTION

ALCOVE INSTALLATION

FIGURE 2A

FIGURE 4A

BACK WALL (M/A)

SIDE WALL (M/L)

B

A

C

BACK WALL (M/A)

45°

SIDE WALL (M/L)

1100/1100L

1400/1400L

1900

A 10" (254mm)

10" (254mm)

22" (560mm)

B

6" (152mm)

6" (152mm)

12" (305mm)

C 2" (50mm)4" (102mm)8" (205mm)

NOTE:CLEARANCES ARE UNABLE TO BE REDUCED FOR THE 1150 BY USING

DOUBLE WALL PIPE.

FIGURE 4B