Gas piping, Warning, Caution – PB Heat MIH User Manual

Page 16

14

1. Size and install the gas supply piping properly in

order to provide a supply of gas sufficient to meet

the maximum demand without undue loss of

pressure between the meter and the boiler.

2. Determine the volume of gas to be provided to the

boiler in cubic feet per hour. To obtain this value,

divide the Btu per hour rating (on the boiler rating

plate) by the heating value of the gas in Btu per

cubic feet. Obtain the heating value of the gas from

the gas supplier. As an alternative, use Table 5.1, 5.2

or 5.3 on the next page to obtain the volume of gas

to be provided to the boiler.

3. Use the value obtained above as the basis for piping

sizing. Size the gas piping in accordance with Table

5.4. Consult the National Fuel Gas Code ANSI

Z223.1/NFPA 54 and/or CAN/CSA B149.1, Natural

Gas and Propane Installation Code for proper sizing

options.

4. Locate the drop pipe adjacent to, but not in front of

the boiler.

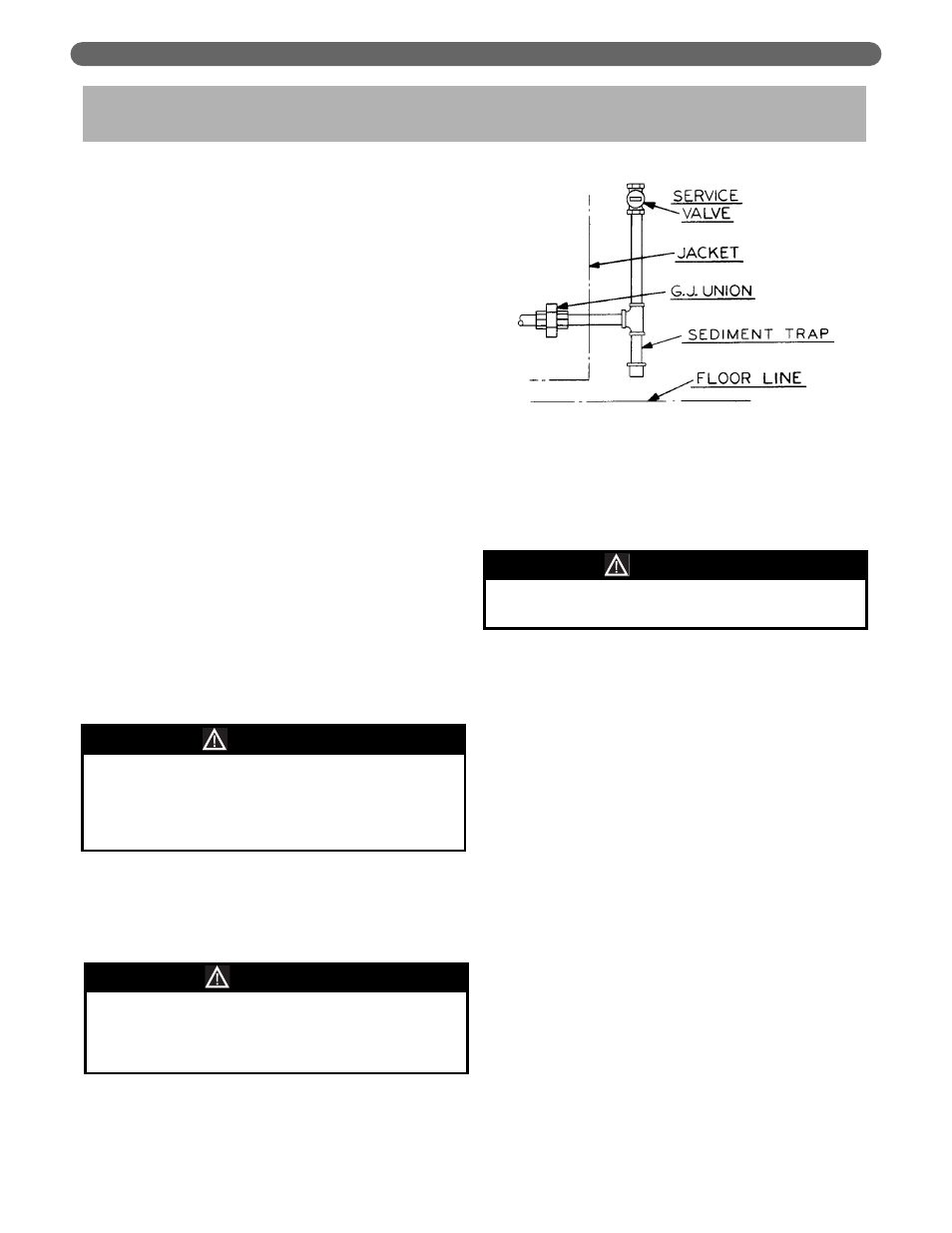

5. Install a sediment trap. See Figure 5.1. Locate a tee

in the drop pipe at same elevation as the gas inlet

connection to the boiler. Extend the drop pipe to a

pipe cap.

6. Install a ground joint union ahead of the gas control

assembly to permit servicing of the control. Some

local codes require an additional service valve when

using the combination gas controls. If your code

requires such a valve, a suggested location is shown

in Figure 5.1.

7. Check piping for leaks.

Use an approved gas detector, a non-corrosive leak

detection fluid or other leak detection method. If

leaks are found, turn off all gas flow and repair as

necessary.

8. Disconnect the boiler and its individual shut-off valve

from the gas supply piping system during any

pressure testing of that system at test pressure in

excess of 1/2 psig (3.5 kPa).

Isolate the boiler from the gas supply piping system

by closing its individual service valve during any

pressure testing of the gas supply piping system at

test pressure equal to or less than 1/2 psig (3.5 kPa).

9. Minimum permissible supply pressure for purposes of

input adjustment:

MI-09 Standing Pilot

Natural Gas

5.2

″ WC (1.3 kPa)

All other MI/MIH

Natural Gas

5.0

″ WC (1.2 kPa)

All MI LP Gas

11.0

″ WC (2.7 kPa)

Maximum permissible supply pressure to the boiler:

All MI/MIH Natural Gas

13.5

″ WC (3.5 kPa)

All MI LP Gas

13.5

″ WC (3.5 kPa)

5. GAS PIPING

Figure 5.1: Gas Connection to Boiler

When checking for leaks, do not use matches,

candles, open flames or other methods that provide a

source of ignition. This can ignite a gas leak,

resulting in fire or explosion.

WARNING

Use a pipe joint sealing compound that is resistant to

the action of liquefied petroleum gas. A non-resistant

compound may lose sealing ability in the presence of

this gas, resulting in a gas leak and fire or explosion

potential.

WARNING

Do not subject the gas valve to more than 1/2 psi (3.5

kPa) pressure. Doing so may damage the valve.

CAUTION

GAS PIPING