Miter slot alignment, Tilt stop adjustment – Powermatic 2000 User Manual

Page 16

16

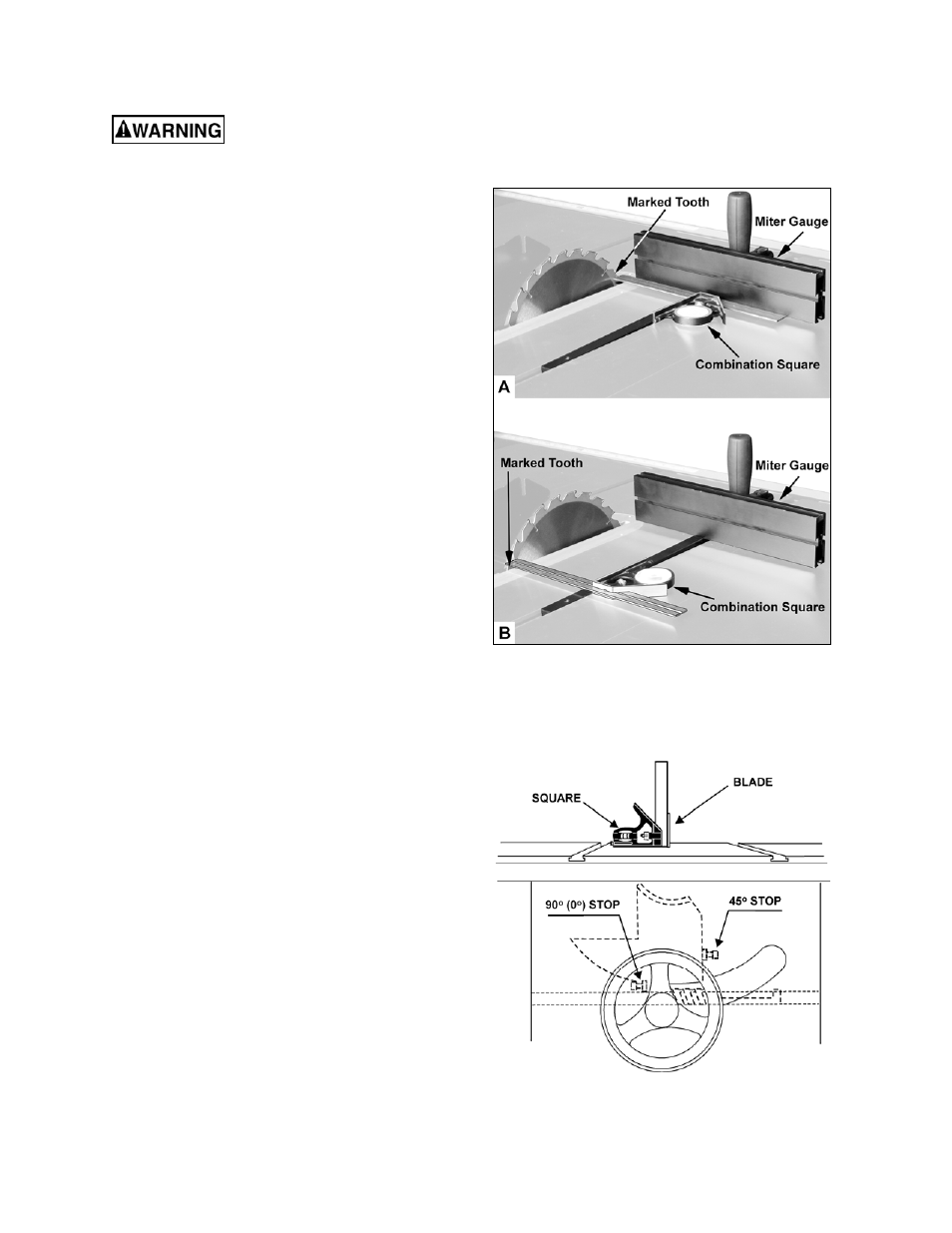

Miter Slot Alignment

Disconnect machine from

power source before making this adjustment.

To check the alignment of the miter slot to the

blade:

1. Raise the blade to its maximum height at the

90º vertical position (0º on scale).

2. Mark one tooth with a grease pencil and

position the tooth slightly above the top edge of

the table at the front.

3. Raise the miter gauge slightly out of its slot to

serve as a shoulder. Using a combination

square against the side of the bar, slide the

scale over until it touches the tip of the blade,

and lock the scale in position (A, Fig. 13).

4. Rotate the marked tooth so that it is slightly

above the table top at the rear (B, Fig. 13) and

using the square as before, check whether the

distance to the blade is the same.

5. If the distance is not the same, loosen the four

mounting screws that lock the table top to the

cabinet (two in front, two in back).

6. Nudge the table to bring the miter slot in line

with the blade.

The blade must be kept centered with the slot

in the table insert to ensure clearance at both

the 90º and 45º positions.

7. After alignment, secure the table to the cabinet

by re-tightening the four mounting screws.

Tilt Stop Adjustment

1. Adjust the blade tilt for 90º as described in

Blade Tilt Adjustment on page 14.

2. Using a combination square, check the

90º stop (Figure 14 shows the 90º stop being

checked).

3. Adjust the 90º stop position if required, using

the stop screws as shown.

The 90º stop adjustment is accessible though

the left side opening. 14mm wrenches are

required to loosen the lock nut and adjust the

screw.

4. Check the accuracy of the pointer at 0º (blade

at 90º vertical position)

and adjust if required.

5. Adjust the blade tilt for 45º. If required, adjust

the stop and pointer in the same manner. as

above. The 45º stop adjustment is accessible

though the slot on the front of the cabinet.

Figure 13

Figure 14