Service and adjustments, Warning – Poulan Pro PP5500P User Manual

Page 11

11

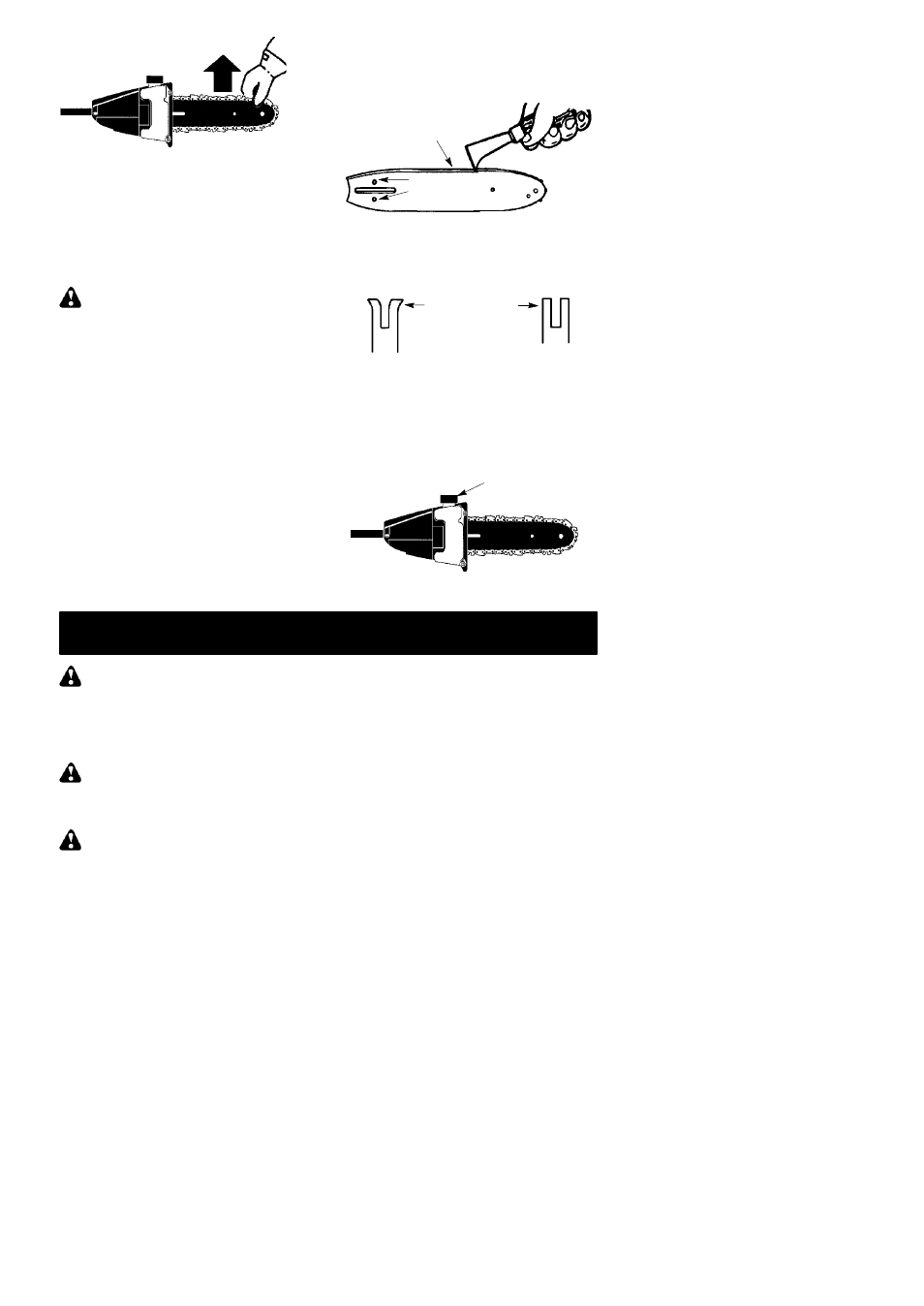

7. Use a screwdriver to move chain around

guide bar.

8. If chain does not rotate, it is too tight.

Slightly loosen bar clamp nut and loosen

chain by turning the adjusting screw 1/4

turn counterclockwise. Retighten bar

clamp nut.

9. If chain is too loose, it will sag below the

guide bar and needs to be tightened fol-

lowing above procedure.

WARNING:

DO NOT operate the

pruner if the chain is loose. If the pruner is op-

erated with a loose chain, the chain could

jump off the guide bar and result in serious in-

jury.

CHECK CHAIN SHARPNESS

A sharp chain makes wood chips. A dull chain

makes a sawdust powder and cuts slowly.

See CHAIN SHARPENING in the SERVICE

AND ADJUSTMENTS section.

BAR MAINTENANCE

If your pruner cuts to one side, has to be

forced through the cut, or been run with an im-

proper amount of bar lubrication it may be

necessary to service your bar. A worn bar will

damage your chain and make cutting difficult.

After each use, ensure ON/STOP switch is in

the STOP position, then clean all sawdust

from the guide bar and sprocket hole.

To maintain guide bar:

S

Move ON/STOP switch to the STOP posi-

tion and disconnect spark plug (or discon-

nect unit from power source).

S

Loosen and remove bar clamp nut and chain

brake. Remove bar and chain from pruner.

S

Clean the oil holes and bar groove after

each 5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Oil Holes

S

Burring of guide bar rails is a normal

process of rail wear. Remove these burrs

with a flat file.

S

When rail top is uneven, use a flat file to re-

store square edges and sides.

Correct Groove

Worn Groove

File Rail Edges

and Sides

Square

Replace guide bar when the groove is worn, the

guide bar is bent or cracked, or when excess

heating or burring of the rails occurs. If replace-

ment is necessary, use only the guide bar speci-

fied for your pruner in the repair parts list.

LUBRICATION

Bar Oil

Fill Cap

S

See GUIDE BAR AND CHAIN OIL under

the OPERATION section.

SERVICE AND ADJUSTMENTS

WARNING:

Always stop unit and dis-

connect spark plug wire (or disconnect unit

from power source) before performing main-

tenance, service, or adjustments except for

carburetor adjustments.

CHAIN SHARPENING

WARNING:

Improper chain sharpen-

ing techniques and/or depth gauge mainte-

nance will increase the chance of kickback

which can result in serious injury.

WARNING:

Wear protective gloves

when handling chain. The chain is sharp and

can cut you even when it is not moving.

Conditions which indicate the need for chain

sharpening:

S

Reduction in size of wood chips. The size of

the wood chip will decrease as the chain

gets duller until it becomes more like a pow-

der than a chip. Note that dead or rotted

wood will not produce a good chip.

S

Saw cuts to one side or at an angle.

S

Saw has to be forced through the cut.

Tools required:

S

3/16 inch (4,5 mm) diameter round file and

file holder

S

Flat file

S

Depth gauge tool

TO SHARPEN CHAIN:

1. Move ON/STOP switch to the STOP posi-

tion and disconnect spark plug (or discon-

nect powerhead from power source).

2. Check chain for proper tension. Adjust

chain tension if necessary. See CHECK

CHAIN TENSION section.

3. Sharpen cutters.

S

To sharpen the cutters, position the file

holder level (90

˚) so that it rests on the

top edges of the cutter and depth gauge.

NOTE:

The chain has both left and

right hand cutters.