Operating controls, Operation – Powermatic PF-BS User Manual

Page 13

13

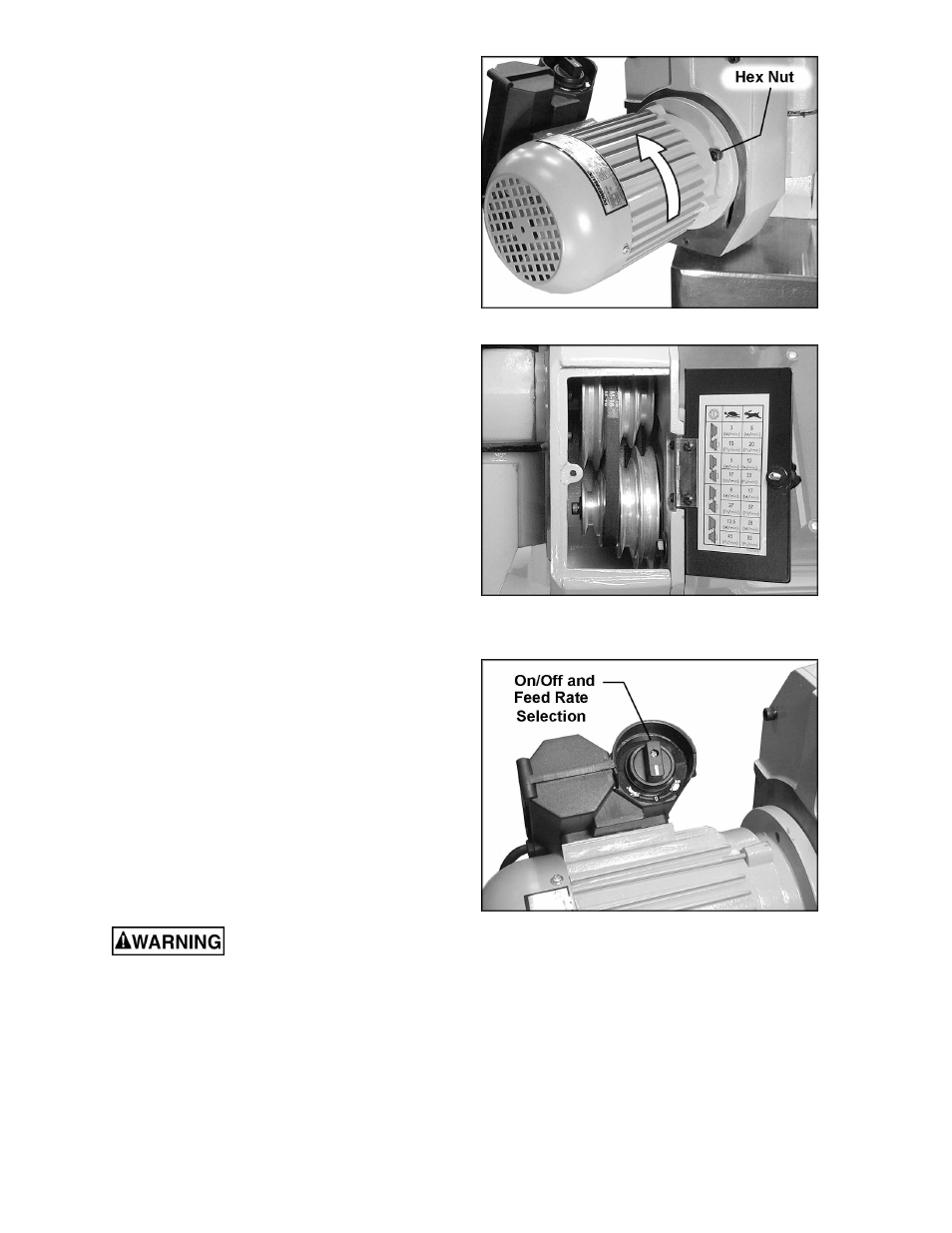

Changing Feed Rate

1. Loosen the two hex nuts (one is shown in

Figure 13) that hold the motor to the motor

mount. Use a 12mm wrench. Do not remove

the hex nuts, loosen them only enough so

that the motor can be pivoted.

2. Pivot the motor counterclockwise, as shown

in Figure 13. This will produce slack in the

belt.

3. Open the pulley cover door (Figure 14) by

unscrewing the knob.

4. Roll the belt into the appropriate pulley

groove for the desired feed rate. A label is

affixed to the inside of the door (Figure 14)

that shows the configurations for belt

position/feed rate in both feet per minute

and meters per minute. This feed rate chart

is also reproduced on page 16.

5. When the belt has been changed, close the

pulley door and tighten the knob.

6. Rotate the motor clockwise to tension the

belt. Proper tension is achieved when the

belt can be deflected approximately 3 to

5mm with slight finger pressure.

7. Tighten the two hex nuts (Figure 13).

Operating Controls

The control switch (Figure 15) turns on the

Stock Feeder motor, and also helps determine

feed rate in conjunction with the pulley position.

“Fast” and “Slow” are identified by the universal

symbols of hare and tortoise.

Operation

IMPORTANT: Before attempting operation of

this stock feeder in conjunction with a band saw,

you should be thoroughly familiar with the

operating and safety instructions that were

included with the band saw.

Keep hands away from

rollers, spring, and other pinch points of the

Stock Feeder during operation. Failure to

comply may cause injury.

The following are basic steps for operating the

Stock Feeder.

1. Make sure the band saw is working properly

and that the blade is sharp; and that all

guards are properly installed.

Figure 13

Figure 14

Figure 15