Assembly – Poulan 530088788 User Manual

Page 5

5

Kickback can also be caused by pinching the

saw chain along the top of the guide bar. This

action may push the guide bar rapidly back

toward the operator. Either of these events

may cause you to lose control of the saw

which could result in serious injury or even

death. DO NOT RELY UPON ANY OF THE

SAFETY DEVICES BUILT INTO YOUR

SAW.

YOU SHOULD USE THE SAW

PROPERLY AND CAREFULLY TO AVOID

KICKBACK. Reduced--kickback guide bars

and low--kickback saw chains reduce the

chance and magnitude of kickback and are

recommended. Your saw has a low kick-

back chain and bar as original equipment.

Repairs on a chain brake should be made by

an authorized servicing dealer. Take your

unit to the place of purchase if purchased

from a servicing dealer, or to the nearest au-

thorized master service dealer.

S

Tip contact in some cases may cause a

lightning fast reverse REACTION, kicking

guide bar up and back toward operator.

S

Pinching the saw chain along the top of the

guide bar may push the guide bar rapidly

back toward the operator.

S

Either of these reactions may cause you to

lose control of the saw which could result

in serious injury. Do not rely exclusively

upon safety devices built into your saw.

NOTE

: If this saw is to be used for commer-

cial logging, a chain brake is required and

shall not be removed or otherwise disabled

to comply with Federal OSHA Regulations

for Commercial Logging. Contact your Au-

thorized

Service

Dealer

or

call

1--800--554--6423.

SAFETY

NOTICE:

Exposure

to

vibrations through prolonged use of gasoline

powered hand tools could cause blood

vessel or nerve damage in the fingers,

hands, and joints of people prone to

circulation disorders or abnormal swellings.

Prolonged use in cold weather has been

linked to blood vessel damage in otherwise

healthy people. If symptoms occur such as

numbness, pain, loss of strength, change in

skin color or texture, or loss of feeling in the

fingers, hands, or joints, discontinue the use

of this tool and seek medical attention. An

anti-vibration system does not guarantee the

avoidance of these problems. Users who

operate power tools on a continual and

regular basis must monitor closely their

physical condition and the condition of this

tool.

SPECIAL NOTICE:

Your saw is equipped

with a temperature limiting muffler and spark

arresting

screen

which

meets

the

requirements of California Codes 4442 and

4443. All

U.S.

forest land and the states of

California, Idaho, Maine, Minnesota, New

Jersey, Oregon, and Washington require

many internal combustion engines to be

equipped with a spark arresting screen by

law. If you operate a chain saw in a state or

locale where such regulations exist, you are

legally responsible for maintaining the

operating condition of these parts. Failure to

do so is a violation of the law. Refer to the

SERVICE section for maintenance of the

spark arresting screen.

STANDARDS:

This saw is listed by Un-

derwriter’s Laboratories, Inc., in accordance

with American National Standards for Gaso-

line--Powered Chain Saw Safety Require-

ments (ANSI B175.1-1991).

Failure to follow all Safety Rules and Precau-

tions can result in serious injury. If situations

occur which are not covered in this manual,

use care and good judgement. If you need

assistance, contact your Authorized Service

Dealer.

ASSEMBLY

Protective gloves (not provided) should be

worn during assembly.

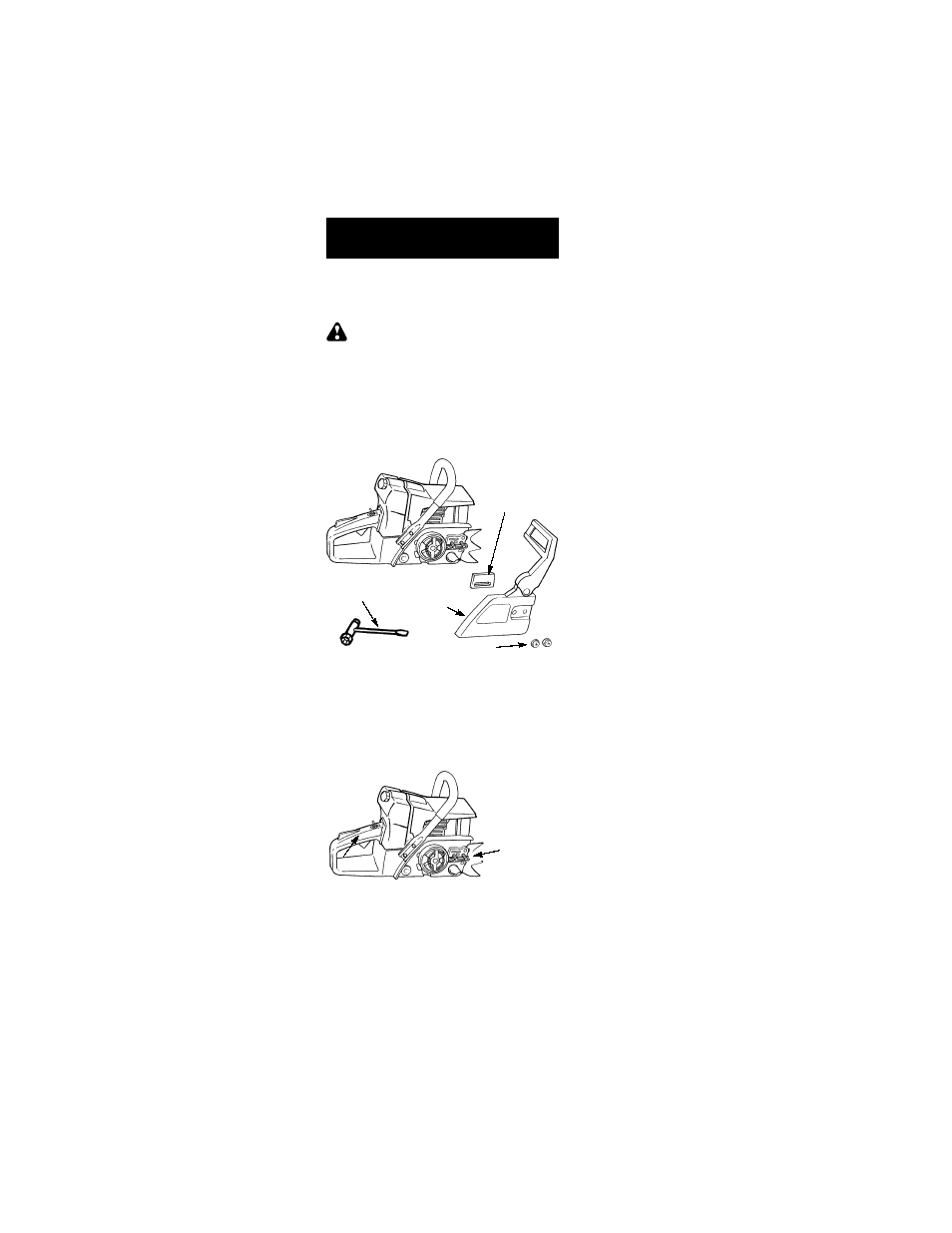

ATTACHING THE BAR & CHAIN

(If not

already attached)

WARNING:

If received assembled,

repeat all steps to ensure your saw is proper-

ly assembled and all fasteners are secure.

Always wear gloves when handling the

chain. The chain is sharp and can cut you

even when it is not moving!

S

Loosen and remove the chain brake nuts

and the chain brake from the saw.

S

Remove the plastic shipping spacer (if

present).

Chain Brake

Chain Brake Nuts

Assembly

Tool

Shipping

Spacer

S

An adjusting pin and screw is used to ad-

just the tension of the chain. It is very im-

portant when assembling the bar, that the

pin located on the adjusting screw aligns

into a hole in the bar. Turning the screw will

move the adjustment pin up and down the

screw. Locate this adjustment before you

begin mounting the bar onto the saw. See

illustration below.

Adjustment

Screw

S

Turn the adjusting screw counterclock-

wise to move the adjusting pin almost as