Side or bottom exhaust, Minimum clearances, Exhaust information (continued) – Panasonic VA-12020 User Manual

Page 4

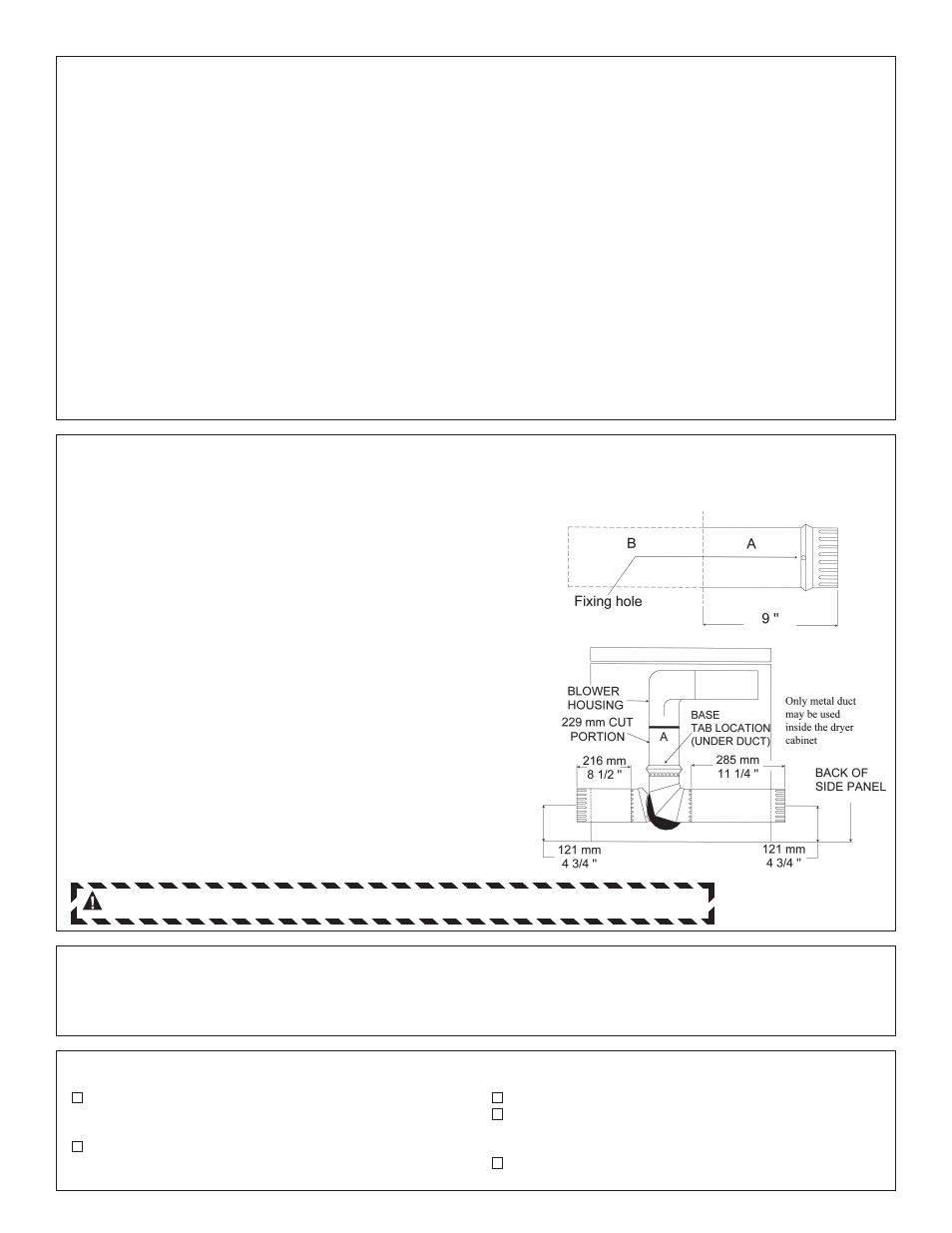

• Detach and remove the desired knockout.

• Remove the screw inside the dryer exhaust duct end.

Keep the screw for step 5. Pull on the duct to remove it.

• Cut the duct as shown. Keep portion A.

• Through the rear opening, locate the tab in the middle of

the dryer base. Lift the tab to about 45˚ using a flat

screwdriver.

• Reconnect and secure the cut portion (A) of the duct to

the blower housing. Make sure that the fixing hole is

aligned with the tab in the base. Use the screw of item 2

to secure the duct in place through the tab on the dryer

base.

• Use standard metal elbows and duct to complete

exhaust system. Insert standard elbow and ducts

through rear and side or bottom openings.

• Cover the opening at the back with the plate (Kit

WE1M454) available from your Local Service Provider.

SIDE OR BOTTOM EXHAUST

STEPS TO CHANGE DRYER TO SIDE OR BOTTOM EXHAUST DIRECTLY ON CABINET

NOTE: Protect your hands and arms from sharp edges when working inside dryer cabinet.

Minimum clearances are – 0" both sides

– 1" at rear

– 88" vertical space from floor to ceiling

MINIMUM CLEARANCES

EXHAUST SYSTEM CHECK LIST

HOOD OR WALL CAP

• Terminate in a manner to prevent back drafts or

entry of birds or other wildlife.

• Termination should present minimal resistance to the

exhaust air flow and should require little or no

maintenance to prevent clogging.

• Wall caps must be installed at least 12" above

ground level or any other obstruction with the

opening pointed down.

SEPARATION OF TURNS

Separate all turns by at least 3 ft. of straight duct,

including distance between last turn and dampered

wall cap. If two turns must be closer than 3 ft., deduct

10 ft. from the maximum lengths shown in the table for

each occurrence.

TURNS OTHER THAN 90˚

• One turn of 45˚ or less may be ignored.

• Two 45˚ turns should be treated as one 90˚.

• Each turn over 45˚ should be treated as one 90˚.

SEALING OF JOINTS

• All joints should be tight to avoid leaks. The male

end of each section of duct must point away from

the dryer.

• Do not assemble the duct work with fasteners that

extend into the duct. They will serve as a collection

point for lint.

• Duct joints can be made air and moisture-tight by

wrapping the overlapped joints with duct tape.

INSULATION

Duct work which runs through an unheated area or is

near an air conditioning duct should be insulated to

reduce condensation and lint build up and be sloped

down toward outdoors.

NOTE: Never install screen inside exhaust duct.

EXHAUST INFORMATION (continued)

Note to Installer:

After Installation check the following:

Exhaust Duct - must meet specs as mentioned in

“Exhaust Information” section of this installation

instructions.

Grounding - Dryer must be properly grounded to

conform to local codes and ordinance

requirements.

Operation - Turn dryer ON and check for heat.

Hand Customer the Use and Care Book - Give

instructions on operating the dryer - answer any

questions.

Give these Installation Instructions to the customer.

WARNING: NEVER LEAVE THE BACK OPENING WITHOUT THE PLATE.