Service, Warning – Poulan PP4620AVHD User Manual

Page 14

14

SERVICE

WARNING:

Disconnect the spark

plug before performing maintenance except

for carburetor adjustments.

We recommend all service and adjustments

not listed in this manual be performed by an

authorized service dealer.

MAINTENANCE SCHEDULE

Check:

Fuel mixture level

Before each use

. . . .

Bar lubrication

Before each use

. . . . . . .

Chain tension

Before each use

. . . . . . .

Chain sharpness

Before each use

. . . .

For damaged parts

Before each use

. .

For loose caps

Before each use

. . . . . .

For loose fasteners

Before each use

. . .

For loose parts

Before each use

. . . . . .

Inspect and Clean:

Bar

Before each use

. . . . . . . . . . . . . . . .

Complete saw

After each use

. . . . . . .

Air filter

Every 5 hours*

. . . . . . . . . . . . .

Chain brake

Every 5 hours*

. . . . . . . .

Spark arresting screen

and muffler

Every 25 hours*

. . . . . . . . .

Replace spark plug Yearly

.

Replace fuel filter

Yearly

. . .

* Hours of Operation

AIR FILTER

CAUTION

: Do not clean filter in gasoline

or other flammable solvent to avoid creating

a fire hazard or producing harmful evapora-

tive emissions.

Cleaning the air filter:

A dirty air filter decreases engine perform-

ance and increases fuel consumption and

harmful emissions. Always clean after 15

tanks of fuel or 5 hours of operation, which-

ever comes first. Clean more frequently in

dusty conditions. A used aire filter can never

be completely cleaned. It is advisable to re-

place your air filter with a new one after every

50 hours of operation, or annually, whichever

comes first.

1. Loosen 3 screws on cylinder cover.

2. Remove cylinder cover.

3. Remove air filter.

4. Clean the air filter using hot soapy water.

Rinse with clean cool water. Air dry com-

pletely before reinstalling.

5. Reinstall air filter.

6. Reinstall cylinder cover and 3 screws.

TIghten securely.

Air Filter

Air Filter

Screws

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

As the unit is used, carbon deposits build up

on the muffler and spark arresting screen,

and must be removed to avoid creating a fire

hazard or affecting engine performance.

Replace the spark arresting screen if breaks

occur.

CLEANING THE SPARK

ARRESTING SCREEN

Clean every 25 hours of operation or annually,

whichever comes first.

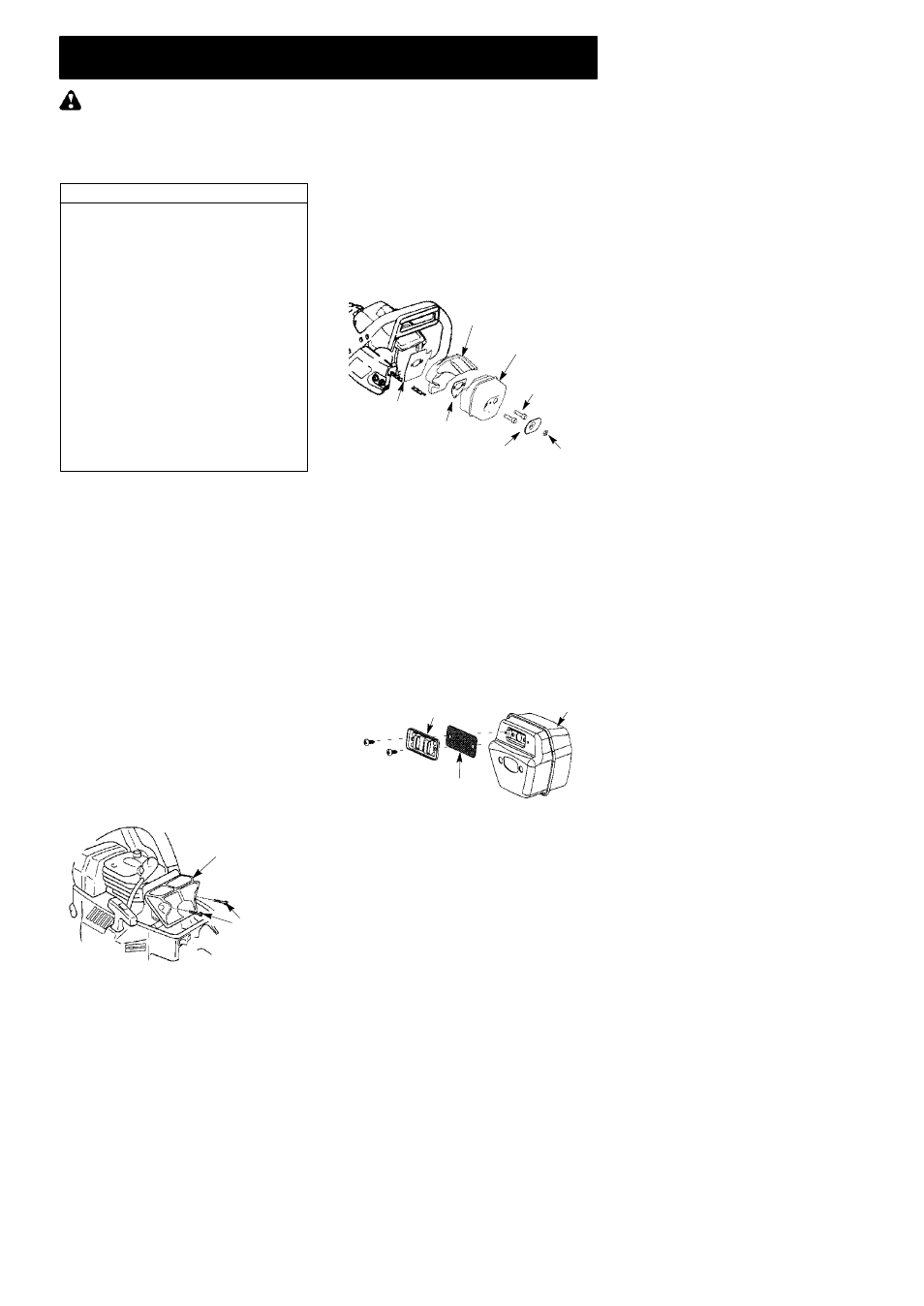

Muffler

Gasket

Muffler

Bolts

Muffler

Locknut

Steel

Backplate

Bolt Cover

Aluminum

Backplate

1. Loosen and remove the 3 cylinder cover

screws. Remove the cylinder cover.

2. Pull off the spark plug boot.

3. Loosen and remove the locknut from the

bolt cover. Remove the bolt cover.

4. Loosen and remove the 2 muffler bolts.

Remove the muffler and backplates. No-

tice the orientation of these parts for re-

assembling.

5. Locate the 2 outlet cover screws on the

muffler. Loosen and remove both

screws. Remove the outlet cover and

spark arresting screen.

Outlet Cover

Spark Arresting

Screen

Screws

Muffler

BACK VIEW OF MUFFLER

6. Clean the spark arresting screen with a

wire brush. Replace screen if any wires

are broken or screen is blocked after

cleaning.

7. Reinstall spark arresting screen.

8. Reinstall outlet cover and 2 screws. En-

sure outlet cover and both screws are re-

installed correctly to prevent damage to

the saw (see illustrations). The exhaust

outlets must face the chain brake (bar

side) of the saw.