Step 2: align guides, Step 3: align blade parallel to guides – Powermatic 511 User Manual

Page 17

17

Step 2: Align Guides

Disconnect saw from power

source before aligning the guides.

If the saw does not cut at 90 degrees, the

guides may not be perpendicular to the rollers.

Adjust as follows:

1. Make sure the rollers are aligned.

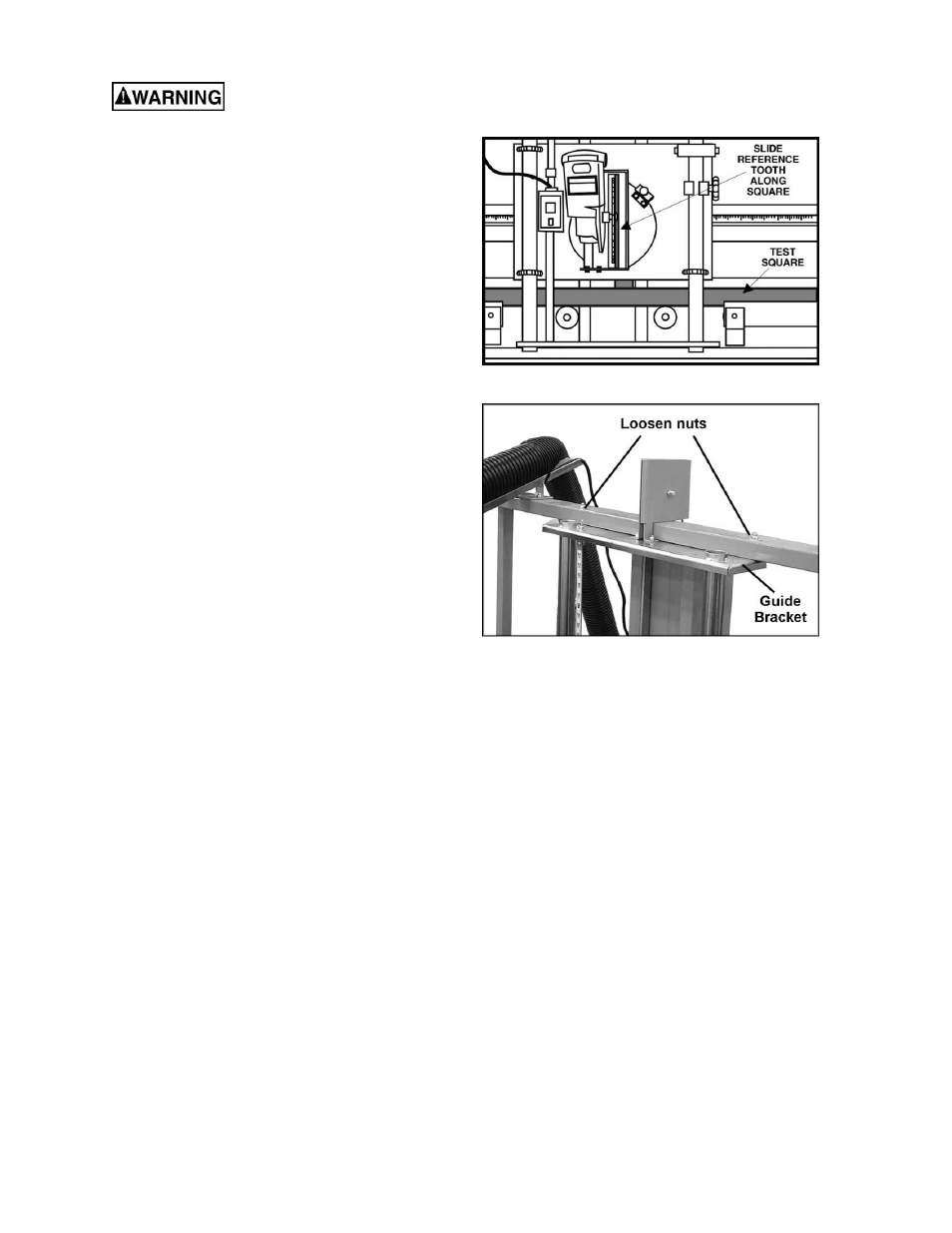

2. Remove the blade guard and mark a blade

tooth as a reference (NOTE: If the saw has

a high speed steel blade, mark a tooth that

points toward the edge of your test square,

which is still clamped above the rollers.)

3. Pull the carriage down until the reference

tooth of the blade just touches the vertical

edge of the test square, Figure 19. Continue

pulling the carriage down; if the blade does

not contact the square, or the blade binds

on the square, the guides are not aligned

properly.

4. Loosen the guide bracket nuts, Figure 20,

but do not remove the bracket. With a dead

blow mallet, strike the bracket on the side in

the direction you want the guides to go. Do

not strike the guides.

5. Confirm the squareness of guides to rollers

as described above. When satisfied, re-

tighten guide bracket nuts.

STEP 3: Align Blade Parallel to Guides

The blade must move parallel to the guides or

tail burning may occur, and the kerf may be

wider than the set of the blade. Always adjust

the rollers and guides before adjusting the

blade. To check for blade alignment:

1. Make sure rollers and guides are aligned

first.

2. If the blade “heels”, or leaves burn marks on

the cut, move the carriage to a crosscut

position and make a test cut. Examine both

sides of the cut to determine which side of

the blade is causing the problem.

3. Disconnect power from the saw.

4. Place your test square on the rollers and

lower the carriage so the test square

overhangs the blade.

5. Place the test square against the blade. The

entire face of the blade should contact the

test square; if it does not, the blade is in

need of alignment.

Figure 19

Figure 20