Gas boiler system commissioning checklist – Baxi Potterton Titanium Condensing Combination Boiler 47-393-40 User Manual

Page 62

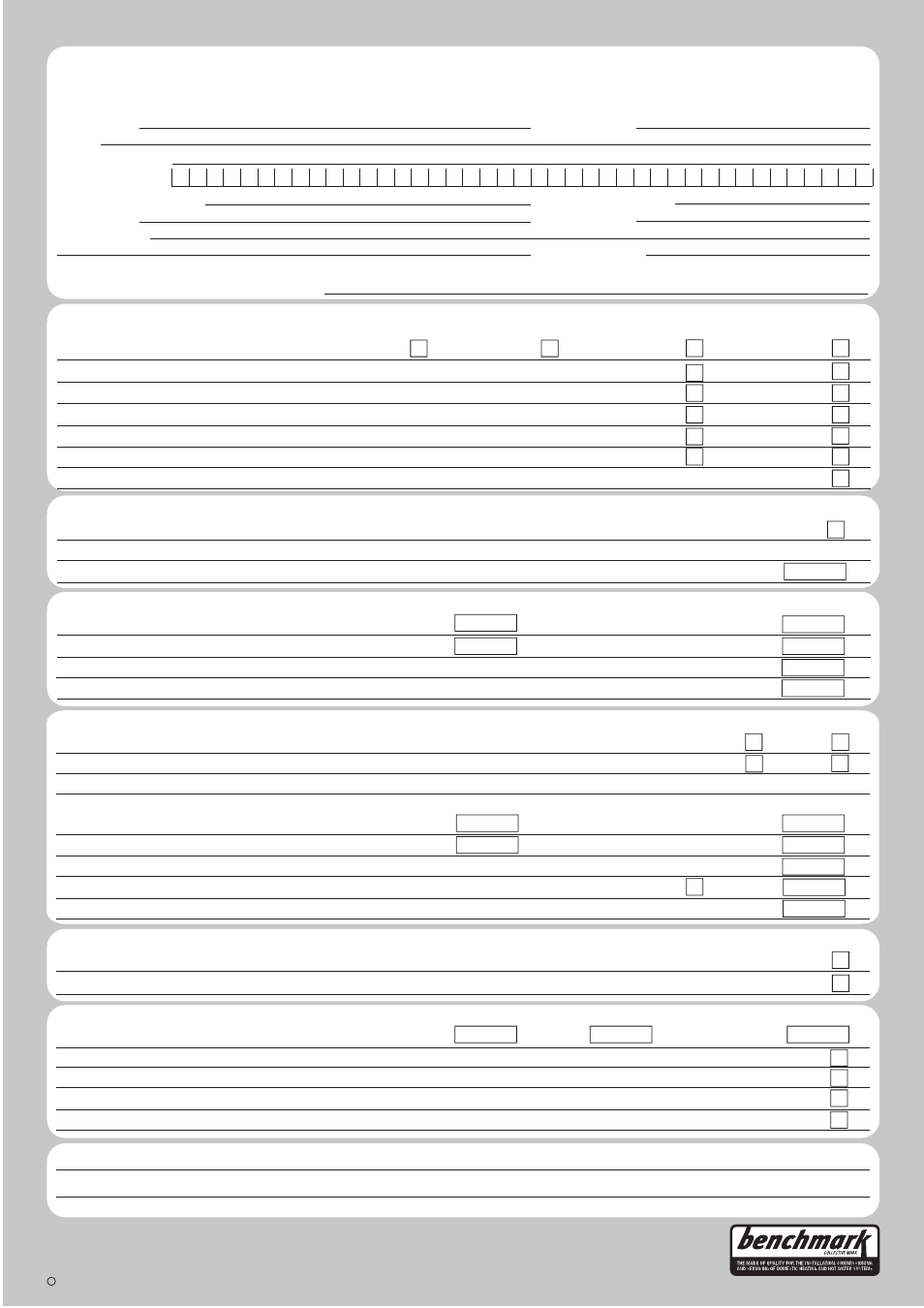

GAS BOILER SYSTEM COMMISSIONING CHECKLIST

This Commissioning Checklist is to be completed in full by the competent person who commissioned the boiler as a means of demonstrating

compliance with the appropriate Building Regulations and then handed to the customer to keep for future reference.

Failure to install and commission according to the manufacturer’s instructions and complete this Benchmark Commissioning Checklist will invalidate the warranty. This

does not affect the customer’s statutory rights

Customer Name

Address

Boiler Make and Model

Boiler Serial Number

Commissioned by (print name)

Company Name

Company Address

To be completed by the customer on receipt of a Buildings Regulations Compliance Certificate*:

Building Regulations Notification Number (if applicable)

Time and Temperature Control to Heating

Room Thermostat and

Programmer/Timer

Programmable

Room Thermostat

Load/Weather

Compensation

Time and Temperature Control to Hot Water

Cylinder Thermostat and Programmer/Timer

Fitted

Fitted

Fitted

Fitted

Yes

Yes

Yes

Yes

Yes

ppm

Ratio

Yes

Yes

Yes

Yes

www.centralheating.co.uk

Yes

Temperature

No

No

Quantity

m /hr

mbar

Gas Inlet Pressure

Gas Inlet Pressure (at maximum rate)

OR

OR

OR

OR

%

OR

CO

OR

litres

Provided

Not Required

Not Required

Not Required

Not Required

Combination Boiler

Optimum Start

Control

Heating Zone Valves

Hot Water Zone Valves

Thermostatic Radiator Valves

Automatic Bypass to System

Boiler Interlock

Telephone Number

Gas Safe Register Number

Telephone Number

Commissioning Date

The system has been flushed and cleaned in accordance with BS7593 and boiler manufacturer’s instructions

What inhibitor was used?

What system cleaner was used?

Gas Rate

Burner Operating Pressure (if applicable)

Central Heating Flow Temperature

Central Heating Return Temperature

Gas Rate

Burner Operating Pressure (at maximum rate)

Cold Water Inlet Temperature

Hot Water has been checked at all outlets

If required by the manufacturer, record the following

The heating and hot water system complies with the appropriate Building Regulations

The boiler and associated products have been installed and commissioned in accordance with manufacturer’s instructions

The operation of the boiler and system controls have been demonstrated to and understood by the customer

(To confirm satisfactory demonstration and receipt of manufacturer’s literature)

The manufacturer’s literature, including Benchmark Checklist and Service Record, has been explained and left with the customer

*

All installations in England and Wales must be notified to Local Authority Building Control (LABC) either directly or through a Competent Persons Scheme.

A Building Regulations Compliance Certificate will then be issued to the customer.

Heating and Hotwater Industry Council (HHIC)

Commissioning Engineer’s Signature

Customer’s Signature

Water Flow Rate

Is the installation in a hard water area? (above 200ppm)

If yes and if required by the manufacturer, has a water scale reducer been fitted?

The condensate drain has been installed in accordance with the manufacturer’s instructions and/or BS5545/BS6798

If the condensate pipe terminates externally, has the pipe diameter been increased and weatherproof insulation fitted?

What type of scale reducer has been fitted?

CONTROLS

Tick the appropriate boxes

ALL SYSTEMS

CENTRAL HEATING MODE

Measure and Record

:

COMBINATION BOILERS ONLY

CONDENSING BOILERS ONLY

ALL INSTALLATIONS

DOMESTIC HOT WATER MODE

Measure and Record

mbar

ft /hr

°C

°C

3

m /hr

mbar

3

3

mbar

ft /hr

l/min

°C

°C

3

CO

2

CO/CO

2

c

62