Powermatic 29 User Manual

Page 12

12

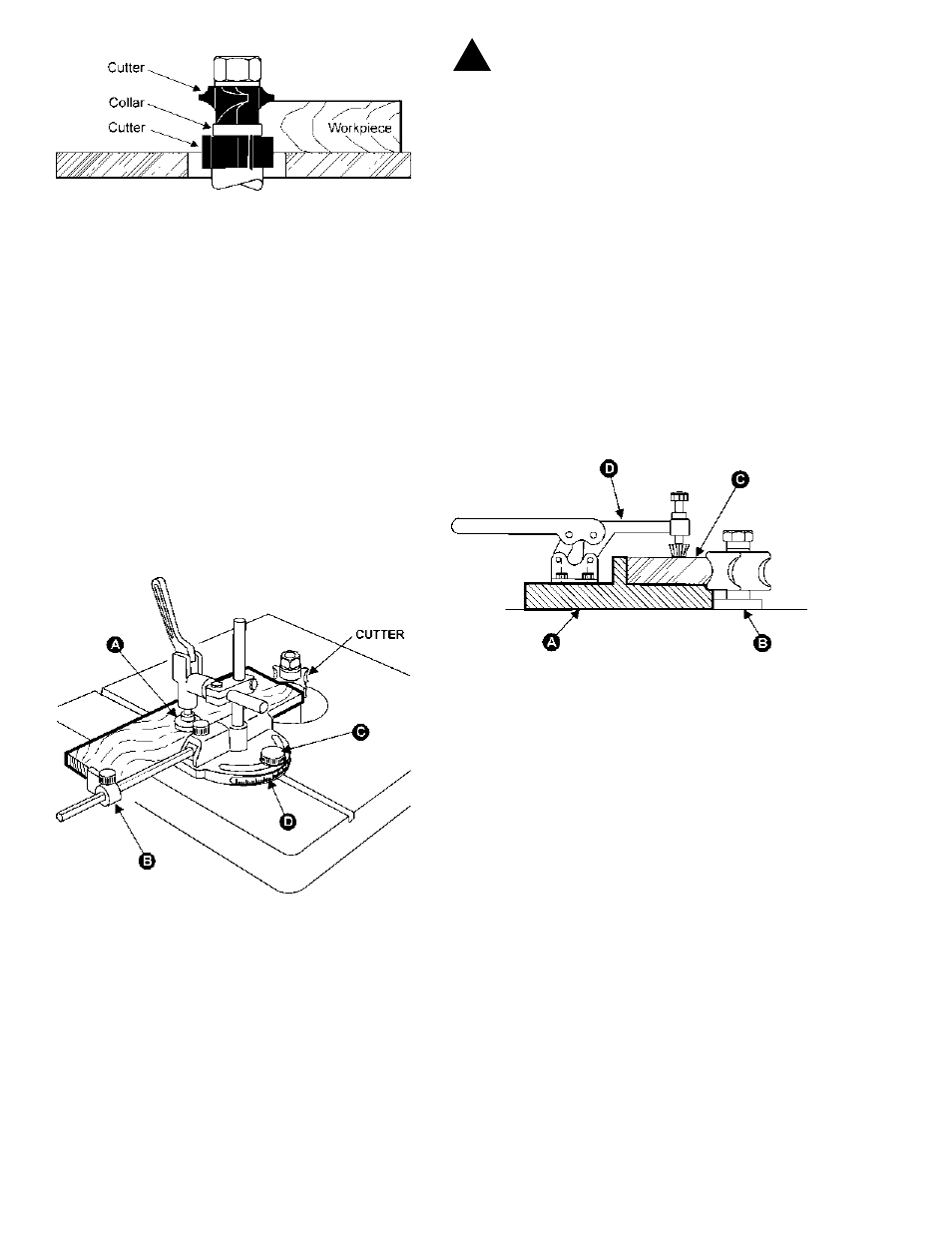

FIGURE 24

NOTE: It is advisable to place the cutter as low as

possible on the spindle to reduce spindle deflection

and ensure the best possible finish. Also make sure

that the contacting surfaces of the cutter are smooth,

clean and without dents.

MITER GAUGE

The miter gauge is used for shaping the end of stock,

usually requiring removal of the fence. To edge-

shape, place the stock against the gauge as shown,

Figure 25. Tighten clamp (A) firmly against stock and

adjust work stop (B) against rear edge of stock. Push

work past cutterhead.

The miter gauge can be adjusted to shape at an angle

by loosening the knob (C) and rotating the gauge body

to the desired angle on the indicator (D).

FIGURE 25

The Shaper can be used for molds, rabbets, grooves,

tenons, copying, etc.:

TENONING

The provided miter gauge and clamp can be used for

tenoning operations.

CAUTION: When using tenoning cutters with

a diameter of 11-13/16" or 9-13/16", run spindle at a

speed not higher than 3,000 RPM. If tenoning cut-

ters have a diameter of 7-7/8" or 6- 3/8", run spindle

at a speed not higher than 6,000 RPM. If tenoning

cutters have a diameter no larger than 3-3/16", run

spindle at 10,000 RPM.

COPYING

When using the same procedure on multiple

workpieces, a jig or template can be made to facili-

tate the operation:

1.

Prepare the jig (A), Figure 26, to accomodate

your original workpiece.

2.

Place the jig (A) against the table insert guide

shoulder (B).

3.

Fasten the new workpiece (C) on the jig (A)

with the clamp (D) and push the assembly past the

cutter.

FIGURE 26

!