Operation – Powermatic 701 User Manual

Page 15

15

Operation

1. Set

the

depth stop to the required depth of cut

(refer to the Depth Stop Adjustment section on

page 12).

2. Place workpiece on table and against the

fence.

3. Adjust the fence until the workpiece is in the

correct position (see the Fence and Clamp

section on page 14).

4. Clamp the workpiece or set the clamp to the

desired height as described in the Fence and

Clamp section on page 14)

Before turning the machine on,

verify that the chuck key is not in the chuck.

5. Turn on the machine and feed the chisel and

auger steadily into workpiece by pulling down

the operating handle.

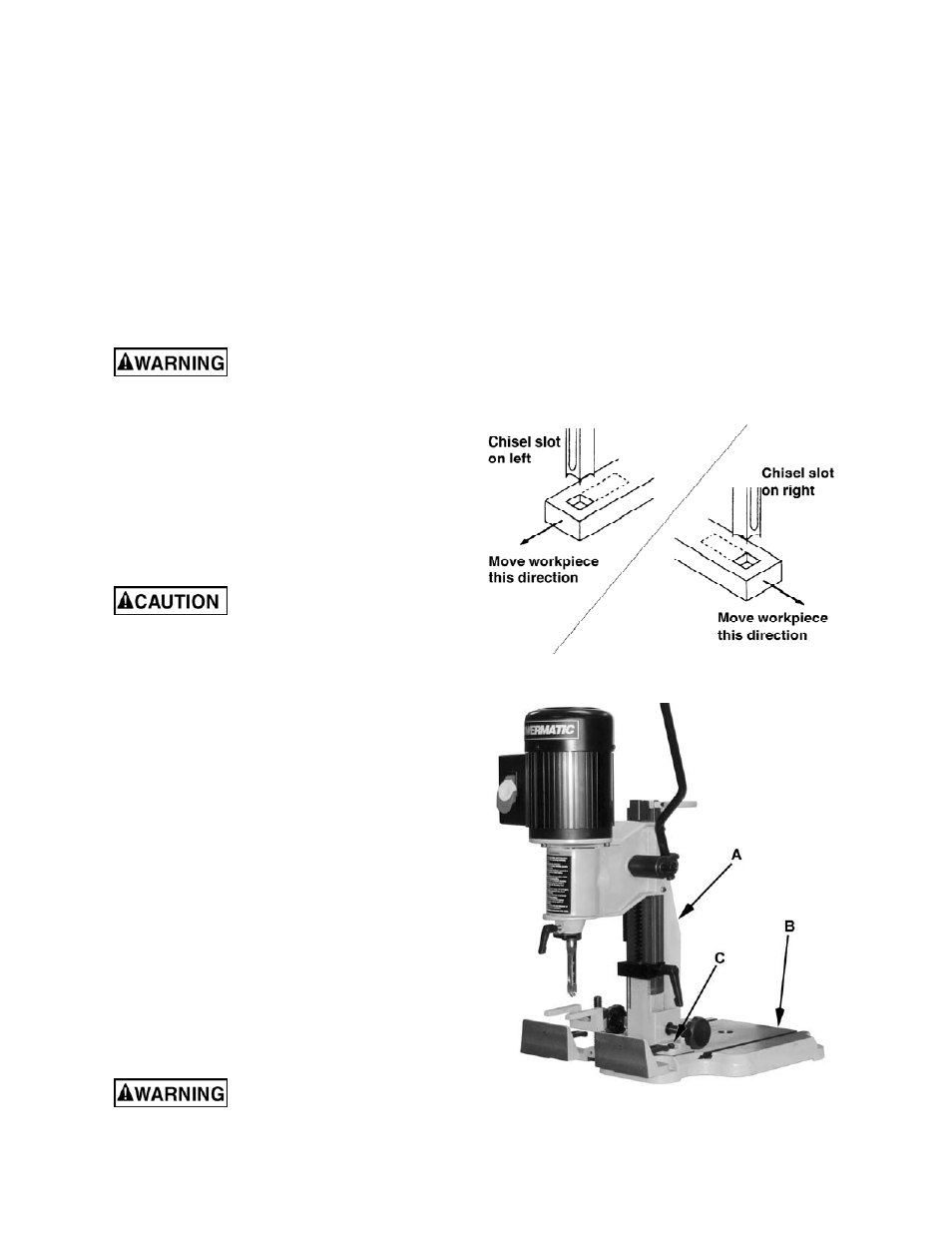

After the first cut, move the workpiece along for

each successive cut. The direction of movement

must allow the chips to clear freely. Move the

workpiece so that the slot in the chisel is releasing

chips into the already cut part of the workpiece

(Figure 14).

Do not have the chisel slot

against the blind end of the mortise, as the

chips will not be able to clear the chisel. This

can cause overheating and possible breakage

of chisel or auger.

When cutting deep mortises, make the cut in

several stages of approximately 1" each, to allow

chips to clear. To prevent breakout at the back of

the workpiece when cutting through mortises, use

a piece of scrap material under the workpiece as

support.

Rotating Column

Referring to Figure 15:

The column can be rotated 180º as shown to

permit mortising large workpieces off the table. To

rotate the column:

1. Using a 4mm hex wrench, remove four screws,

lock washers and flat washers (C) Note: only

one screw is visible in Figure 15.

2. Rotate

the

column (A) 180º.

3. Replace the four screws, lock washers and flat

washers.

The base must be secured to

the work bench.

Figure 14

Figure 15