Idle control operation – Powermate Jobsite 3250 PM0463300 User Manual

Page 3

TOOLS REQUIRED: 7/16” wrench, 3/4" socket and ratchet.

Refer to the parts list and drawing on pages 8 and 9.

WHEEL INSTALLATION

1. Slide 1/2” x 4.50” bolt (item 41) through the wheel

(item 33),then through the wheel bracket, with the offset

side of the wheel hub against the wheel bracket.

2. Thread 1/2” nyloc nut (item 42) onto the bolt and tighten.

3. Repeat above instructions for the remaining wheel.

FOOT INSTALLATION

1. Assemble the foot (item 44) to the carrier channel using a

1/4” x 2.00” bolt (item 43). Thread a 1/4” washer

(item 17) and a 1/4” nyloc nut (item 15) onto the bolt to

secure the assembly.

Caution: Do not over tighten so that the foot material

collapses.

2. Repeat above instructions for the remaining foot.

HANDLE INSTALLATION

1. Slide the reduced ends of the handle (item 18) into the

upright tubes of the base as shown in the diagram.

2. Install the 1/4” x 2.00” bolts (item 43) through the tubes

from the outside.

3. Thread the 1/4” nyloc nuts (item 15) onto the bolts and

tighten.

NOTE: Do not over tighten.

The Idle Control circuit is designed to extend engine life

and improve fuel usage by slowing the engine down to

approximately 2000 RPM in a “No Load” condition. The noise is

also greatly reduced during this condition.

When power is required from the generator an electronic

control module automatically senses current flow in the

electrical outlet and allows the engine to return to full speed or

standard operating condition. Likewise, when the load is

removed, the generator will automatically return to the idle

condition after a 4-5 second delay.

A convenient switch is mounted in the control panel for

easy access and will disable the Idle Control circuitry when in

the off position.

3

English

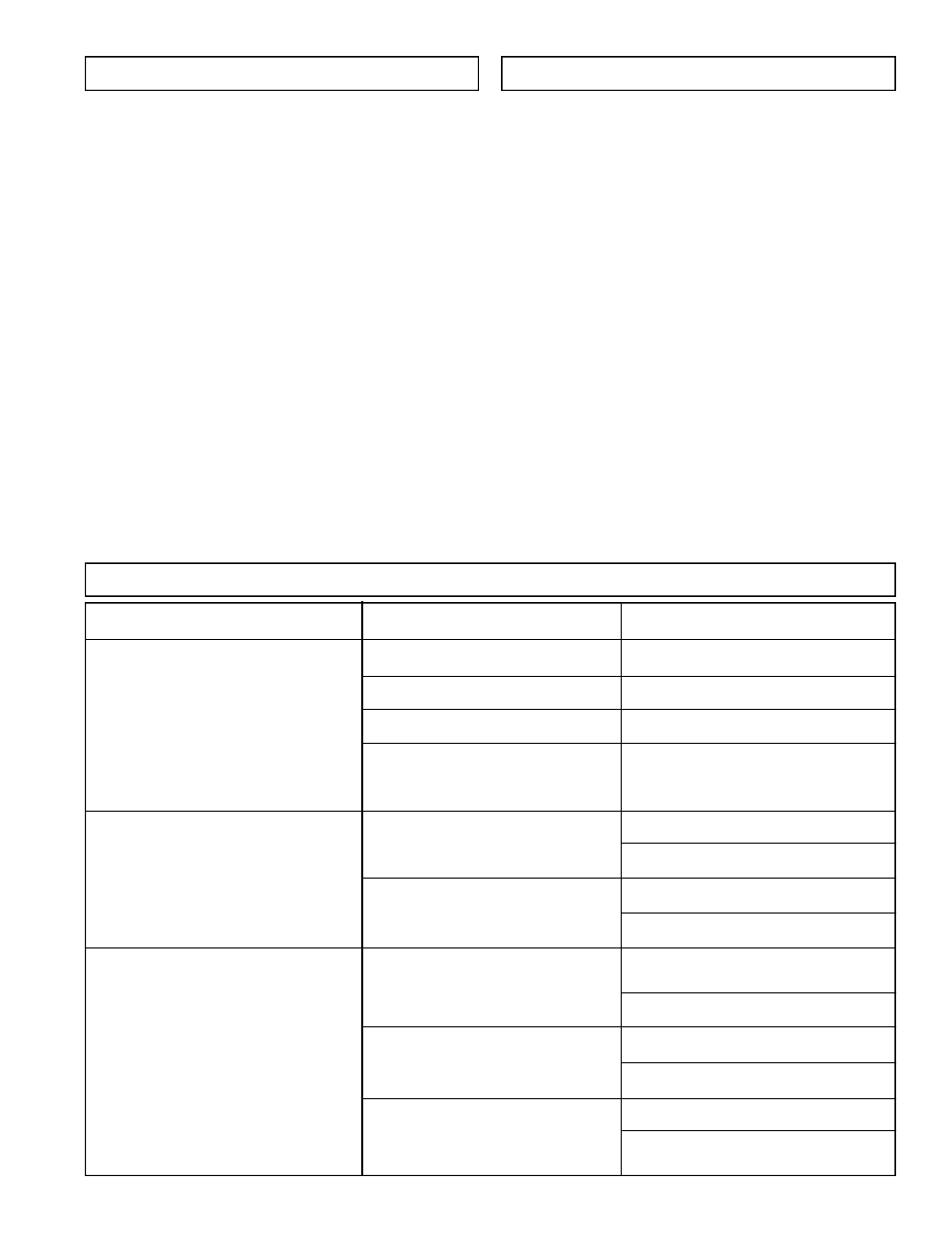

IDLE CONTROL OPERATION

PROBLEM

POSSIBLE CAUSE

SOLUTION

Unit will not idle

Control panel switch not on

Turn to idle on position

Load plugged into receptacle

Unplug load

Poor connection or faulty cord

Check & repair

Bad I.C. module; Bad electro-magnet

Replace

or solenoids; Bad stator

Consult dealer

Unit idles even with load plugged in

Load not heavy enough

Turn idle switch to off position

Increase load

Bad I.C. module

Replace

Consult dealer

Unit tries to idle but won’t stay latched

Electro-magnet or solenoid position

Reset magnet or solenoid position for

incorrect

2000 RPM idle speed

Consult dealer

Flapper bracket loose or bent

Tighten or straighten

Replace flapper. Readjust to 2000 RPM

Engine not running smoothly

Adjust carburetor

Consult dealer

IDLE CONTROL TROUBLE SHOOTING

INSTALLATION INSTRUCTIONS