Diagrams, Cv-655 – Lincoln Electric CV-655 User Manual

Page 37

F-4

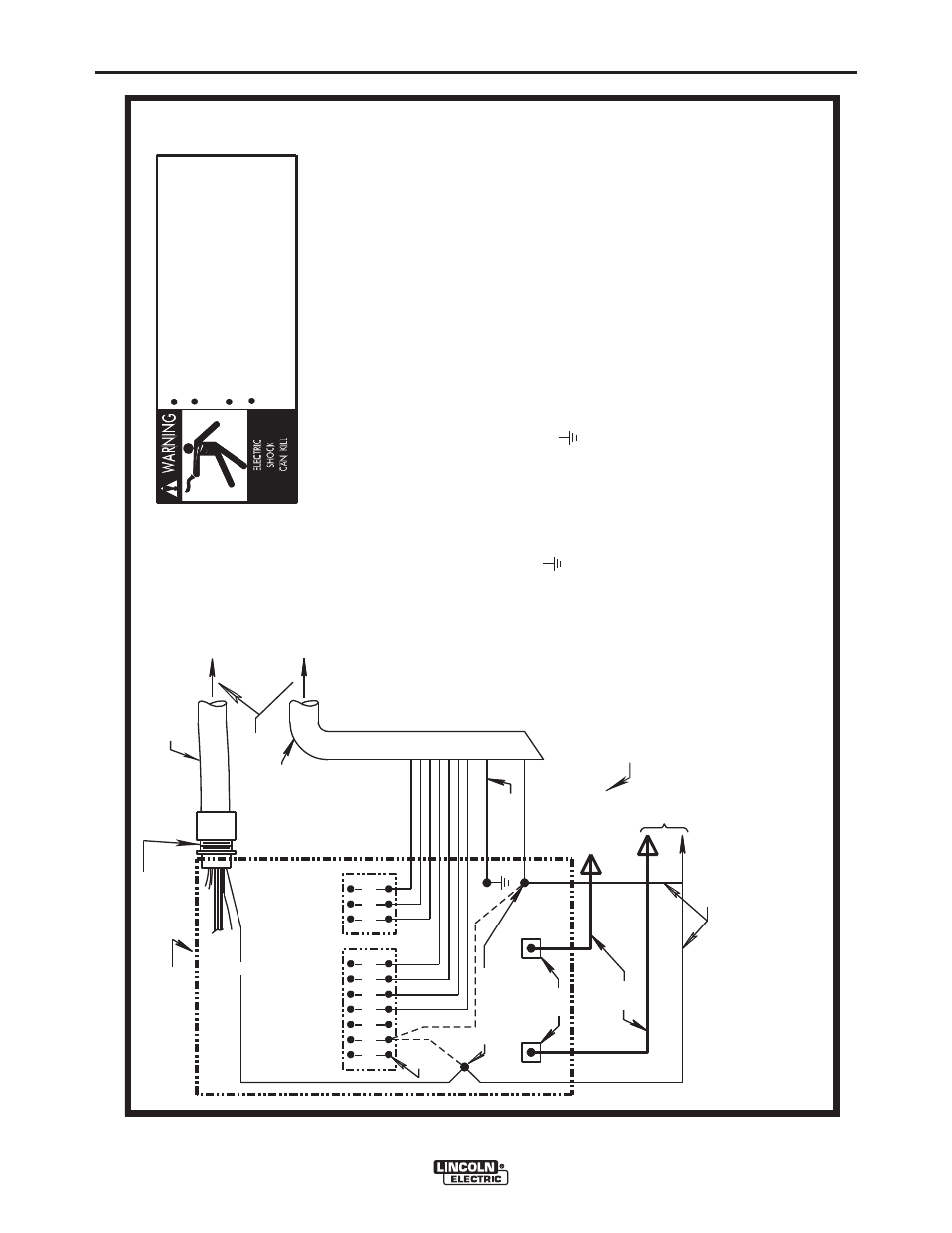

DIAGRAMS

F-4

CV-655

NEGATIVE

POSITIVE

32 31 2 4

GND

21

N.A.

N.D.

TO WORK

POWER SOURCE

Only qualified persons should install, use or

service this machine.

Do not operate with covers removed.

Disconnect power source before

servicing.

Do not touch electrically live parts.

21

FOR CONTROL CABLE

WITH 14 PIN

MS-TYPE

PLUG CONNECTOR

OR

FOR CONTROL CABLE

WITH TERMINAL STRIP

LEAD CONNECTORS

CONTROL CABLE

S22979

N.B. & N.C.

14-PIN

RECEPTACLE

A

B

C

remote voltage sensing work lead may be ordered for this purpose.

N.A. Welding cables must be of proper capacity for the current and

duty cycle of immediate and future applications.

Connect red jumper to pin "S".

Connect white jumper to pin "B".

Above diagram shows electrode connected positive. To change polarity,

N.F.

If lead #21 is to be connected to

follows:

N.D. Connect the control cable ground lead to the frame terminal

marked near the power source terminal strip. The power

source grounding terminal (marked and located near the power

source input power connections) must be properly connected to

electrical ground per the power source operating manual.

Connect it directly to the work piece keeping it electrically

convenience, this extended #21 lead should be taped to the

welding work lead. (If the length of work lead circuit is

short, and connections can be expected to be reliable, then

control cable lead #21 does not need to be extended and can be

directly connected to terminal #21 on the terminal strip. Note

that this is not the preferred connection because it adds error

turn power off, reverse the electrode and work leads at the power source.

physically suitable for the installation. An S16586-[LENGTH]

N.D. & N.F.

INPUT CABLE PLUG

CONTROL CABLE

41

423

1

32

75

76

77

N.F.

21

-

21

+

REMOTE VOLTAGE SENSING LEAD

TO NA-5/-5R

BOLT TO CABLES FROM NA-5/-5R

WIRE CONTACT AS'BLY

box polarity connections. Also refer to note N.F.

Refer to NA-5 or NA-5R Operating Manual for required NA-5 or NA-5R control

FOR ADDITIONAL INSTALLATION INSTRUCTIONS, SEE NA-5 OR NA-5R OPERATING MANUAL.

or from 14-pin receptacle using #14 AWG or larger insulated wire

N.B. Extend lead #21 from control cable with terminal strip connectors

separate from the welding work lead circuit and connection. For

to the NA-5/-5R voltmeter reading.)

N.E. The jumpers on the NA-5/-5R voltage board must be connected as

NA-5/-5R control box.

N.C. Tape up bolted connection if lead #21 is extended.

the terminal strip, connect

When using NA-5/-5R controls above Code 8300, the NA-5/-5R Inch Down

button will not operate unless a jumper is connected between the two tab terminals, labeled "AUTO", located above the transformer on the NA-5/-5R Voltage P.C. board. This jumper, however, will disable the

permitting only Hot Starting techniques to be used.

Cold Starting/Auto-Stop/Touching-Work feature of the NA-5/-5R,

10-30-98F

N.H. Illustration does not necessarily represent actual position of

for more information.

to the #21

terminal that matches work polarity. This connection

must be changed

whenever the electrode polarity is changed.

N.G. For proper NA-5/-5R operation, the electrode cables must be

snugged under

the clamp bar on the left side of the

N.H.

CONNECTION OF NA-5/-5R TO THE CV-655, DC-655 OR DC-600 POWER SOURCE

appropriate output studs. Refer to power source operating manual

For proper setting of switches on power source,

see power source operating manual.