Exposure testing – Lincoln Electric D1.8 User Manual

Page 22

22

D1.8 Seismic Supplement Welding Manual

www.lincolnelectric.com

Exposure Testing:

Lincoln Electric Approved Filler Metal per AWS D1.8/D1.8M:2009, Subclause 6.1.3

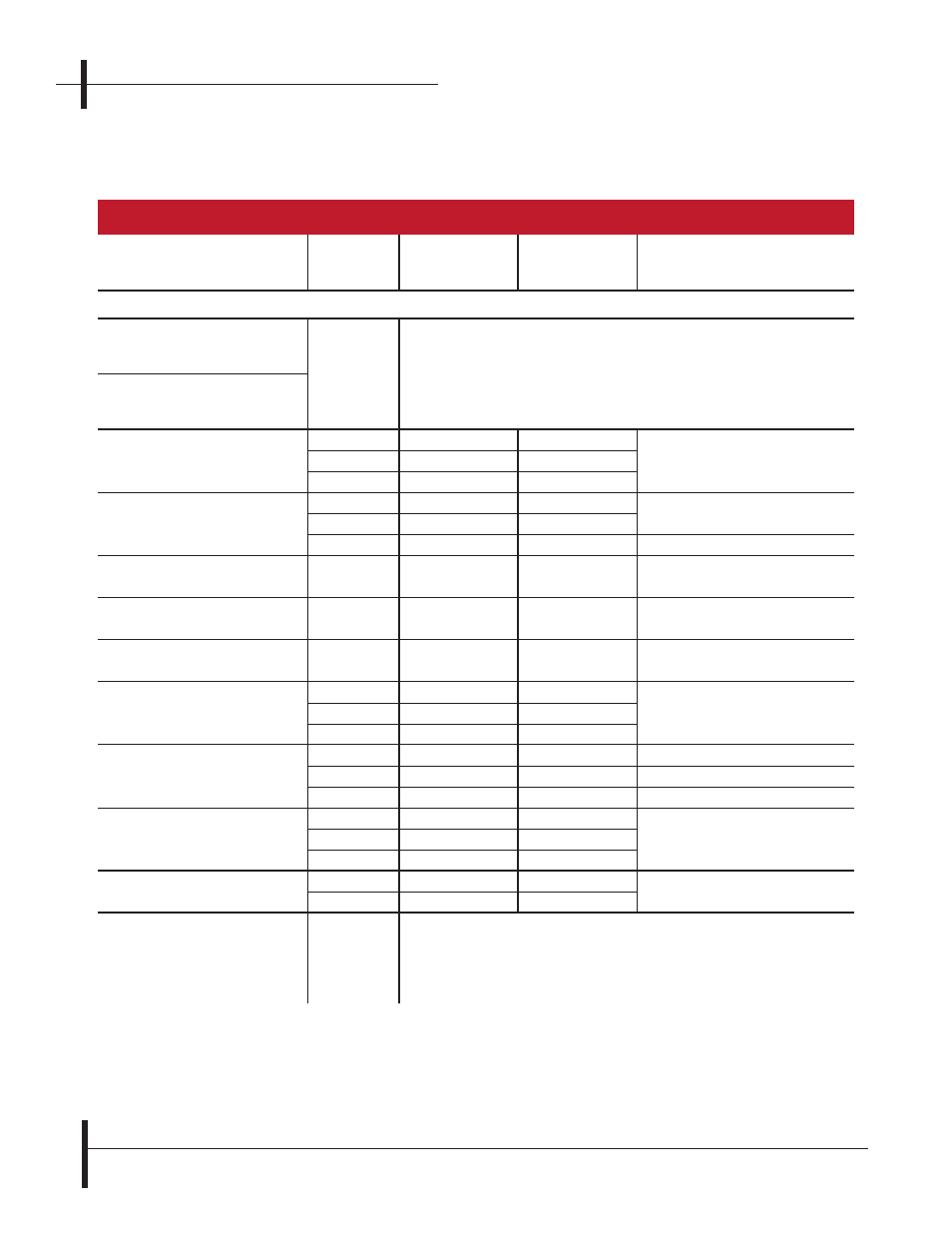

TABLE 3: HEAT INPUT LIMITS FOR DEMAND CRITICAL WELDS

Product Name

Diameters

Available

High Heat Input

inches avg.

Low Heat Input

inches avg.

Exposure Time @

80°F / 80% Relative Humidity

Filler Metal with 70 ksi Minimum Tensile Strength Requirement per AWS

Excalibur

®

7018 MR

AWS E7018 H4R

3/32

1/8

5/32

3/16

7/32

1/4

No heat input testing required

Excalibur

®

7018-1 MR

AWS E7018-1 H4R

Innershield

®

NR-232

AWS E71T-8

0.068

74

29

1 Week

0.072

73

31

5/64

76

32

Innershield

®

NR-233

AWS E71T-8

1/16

74

33

8 Weeks

0.072

67

31

5/64

86

32

1 Week

Innershield

®

NR-305

AWS E70T-6

3/32

64

37

1 Week

Innershield

®

NR-311 Ni

AWS E70T7-K2

3/32

80

45

—

Outershield

®

71 Elite

AWS E71T-1C-H8, E71T-9C-H8

1/16

65

30

8 Weeks

UltraCore

®

70C

AWS E70T-1C-H8, E70T-9C-H8

1/16

79

32

8 Weeks

3/32

80

38

5/64

80

32

UltraCore

®

71C

AWS E71T-1C-H8, E71T-9C-H8

0.045

80

31

8 Weeks

0.052

81

28

—

1/16

82

28

8 Weeks

UltraCore

®

71A85

AWS E71T-1M-H8, E71T-9M-H8

0.045

82

28

8 Weeks

0.052

81

31

1/16

81

28

Metalshield

®

MC-706

AWS E70C-6M-H4

0.045

62

34

72 Hours

1/16

61

34

SuperArc

®

L-50

AWS ER70S-3

0.030

0.035

0.045

0.052

1/16

No heat input testing required No heat input testing required