Lincoln Electric IM481-B User Manual

Page 20

–

20

–

OUTPUT CONTROL “LOCAL-REMOTE” SWITCH

The Output Control toggle switch on the control panel

labeled “Local-Remote” gives the operator the option

of controlling the output at the machine control panel

or at a remote station. For remote control, the toggle

switch is set in the “Remote” position and controlled at

the wire feed unit control, or by connecting a K775

control to terminals 75, 76, and 77 on the terminal

strip at the front of the machine, or by connecting a

K857 control with a K864 adapter to the 14-pin con-

nector on the front of the machine. For control at the

machine control panel (Output Voltage control dial),

the toggle switch is set in the “Local” position.

(Exception: When used with an LN-9, LN-9 GMA or

NA-5 wire feeder, the Output Control switch must be

in the “Remote” position or automatic shutdown of the

LN-9 or NA-5 may occur.)

POLARITY SELECTION

Polarity selection is made by appropriately connecting

the electrode and work welding cables to either the

“

+

” terminal or to the “

-

” terminal. Select “Voltmeter”

switch for “

+

” or “

-

” electrode for the remote (#21)

work sensing lead.

VOLTMETER SWITCH

Select “

+

” for positive electrode or “

-

” for negative

electrode. This switch selects electrode polarity for the

remote (#21) work sensing lead of automatic or semi-

automatic equipment.

THERMAL PROTECTION LIGHT

The amber thermal protection light will be lit if either of

the two protective thermostats have opened. The out-

put power will be disabled but input power will still be

applied to the welder.

115 VAC and 42 VAC AUXILIARY POWER AND

CONTROL CONNECTIONS

14-Pin Connector

The 14-pin connector receptacle (type MS-3102A-20-

27SX) supplies auxiliary power.

42 VAC is available at receptacle pins I and K.

A 10 amp circuit breaker protects this circuit.

115 VAC is available at receptacle pins A and J

(except on the European model). A 10 amp circuit

breaker protects this circuit. Note that the 42 VAC and

115 VAC circuits are electrically isolated from each

other.

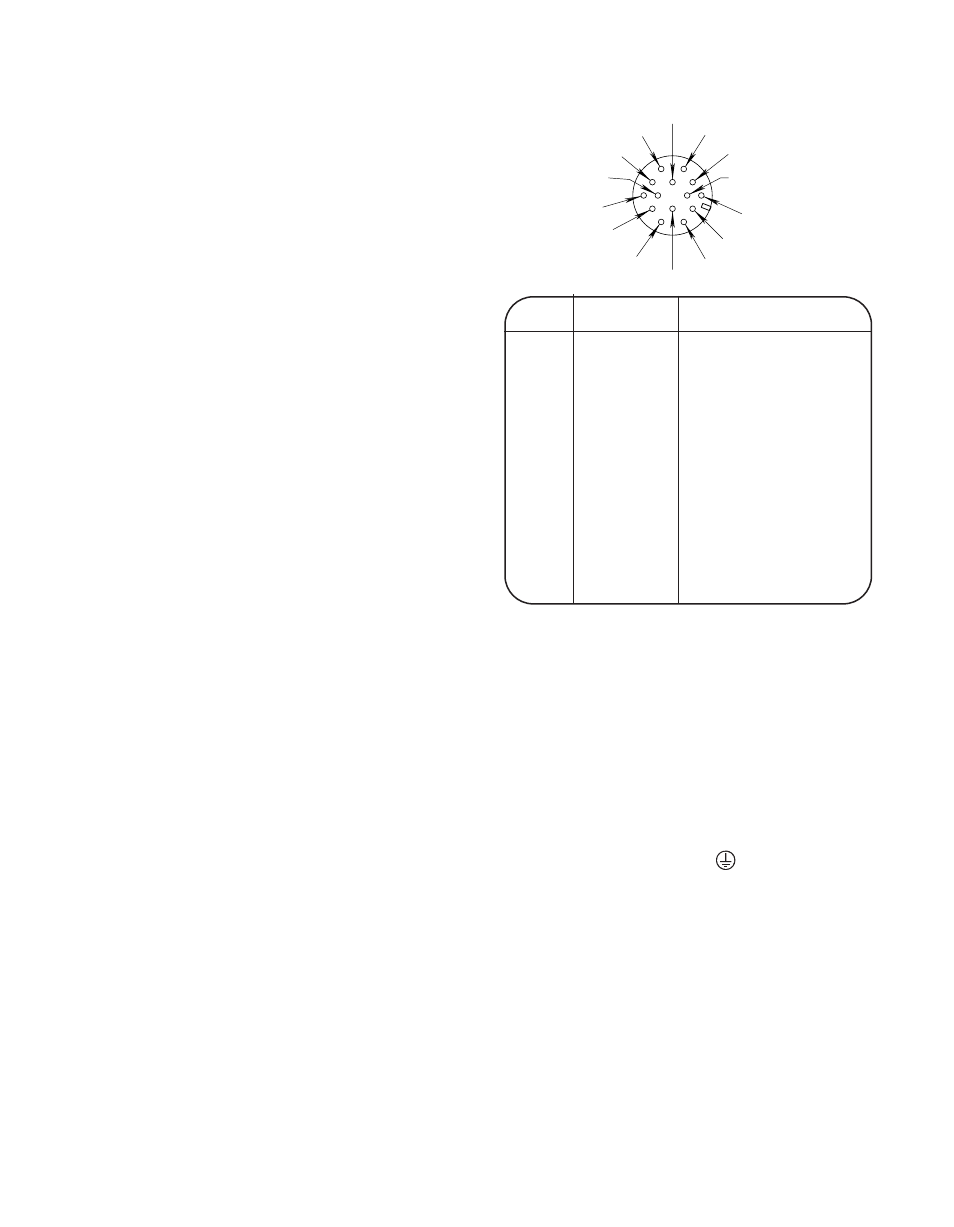

FRONT VIEW OF 14-PIN CONNECTOR

RECEPTACLE

PIN

LEAD NO.

FUNCTION

A

32

115 VAC (Export Model Only)

B

GND

Chassis Connection

C

2

Trigger Circuit

D

4

Trigger Circuit

E

77

Output Control

F

76

Output Control

G

75

Output Control

H

21

Work Connection

I

41

42 VAC

J

31

115 VAC (Export Model Only)

K

42

42 VAC

L

---

---

M

---

---

N

---

---

F=76

G=75

H=21

I=41

J=31

K=42

A=32

B=GND

C=2

D=4

E=77

L

N

M

F = 7 6

G = 7 5

H = 2 1

I = 4 1

J = 3 1

K = 4 2

A = 3 2

B = G N D

C = 2

D = 4

E = 7 7

L

N

M

Terminal Strip Connections

Terminal strip TS2 located behind the hinged control

panel on the front of the power source supplies 115

VAC. A 10 amp circuit breaker protects this circuit.

This 115 VAC is also available in the 14-pin connector

(except on the European model).

Terminal strip TS1 also located behind the hinged

control panel allows for connecting of a K775 remote

control to terminals 75, 76, and 77.

A chassis ground screw is provided below the terminal

strips marked with the symbol for connecting the

automatic equipment grounding wire or remote control

grounding wire.

To gain access to the terminal strips simply remove

the two #10 sheet metal screws from the top of the

welder nameplate. Tilt panel forward so it rests in a

horizontal position. See Table above for lead number

functions.