Lincoln Electric P223 FLUX User Manual

P223 flux, Mechanical properties, Tested on pipe

P223 FLUX

AWS A5.17-97: F7A4-EM12K and A5.23-97: F8A2-EA1-A2

Publication C5.10.1 12/03

www.lincolnelectric.com

Lincolnweld

®

P223 flux is an industry

standard for spiral pipe welding on

up to X80 grade pipe, especially

where good impact properties are

required. It is also well-suited for

longitudinal seam welding on pipe,

producing a low bead profile with

very straight edges, while minimizing

undercuts. Its fast freezing slag

makes it ideal for even small diame-

ter pipe. In most cases, the slag is

self-peeling. For these same rea-

sons, P223 is an excellent choice for

many two-pass welding applications.

While designed for two-pass welding

applications, P223 is a neutral flux

which is also suitable for use in mul-

tiple pass welding with mild steel

and low alloy electrodes.

ADVANTAGE LINCOLN

• The weld deposits of neutral

P223 flux are extremely resistant

to procedural variations.

• Fast solidification of weld metal

and slag for excellent bead

appearance.

• Low dust levels make handling at

the work station clean and easy.

• Excellent weld profiles with straight

and consistent weld bead edges.

• Fast freezing slag makes P223

suitable for smaller diameter pipe.

• Slag is self-peeling on most appli-

cations.

• Designed to deliver Charpy

V-Notch impact properties that

exceed most line pipe require-

ments.

• Low diffusible hydrogen levels.

• Manufactured under a quality

system certified to ISO 9001.

TYPICAL APPLICATIONS

• Oil and gas line pipe fabrication

through X-80 grades.

• Single pass or multiple pass

welding.

• Single arc or multiple arc (up to

3 arc tandem welding).

• Straight seam or spiral seam

welding.

PRODUCT INFORMATION

• Basicity Index: 1.60

• Particle Size:

+12 Mesh 2% max.

-12/+100 Mesh 96% min.

-100 Mesh 2% max.

• Density: 1.3 g/cm

3

CONFORMANCES

For Mild Steel:

Lincolnweld

®

L- 61

AWS A5.17-97: F7A4-EM12K

ASME SFA-5.17

For Low Alloy Steel:

Lincolnweld

®

L-70

AWS A5.23-97: F8A2-EA1-A2

ASME SFA-5.23

RECOMMENDED ELECTRODES

Single Pass or Two-Pass Welds:

Lincolnweld

®

L-61, AWS EM12K

Lincolnweld

®

L-70, AWS EA1

(intended for applications requiring

robust Charpy impact properties).

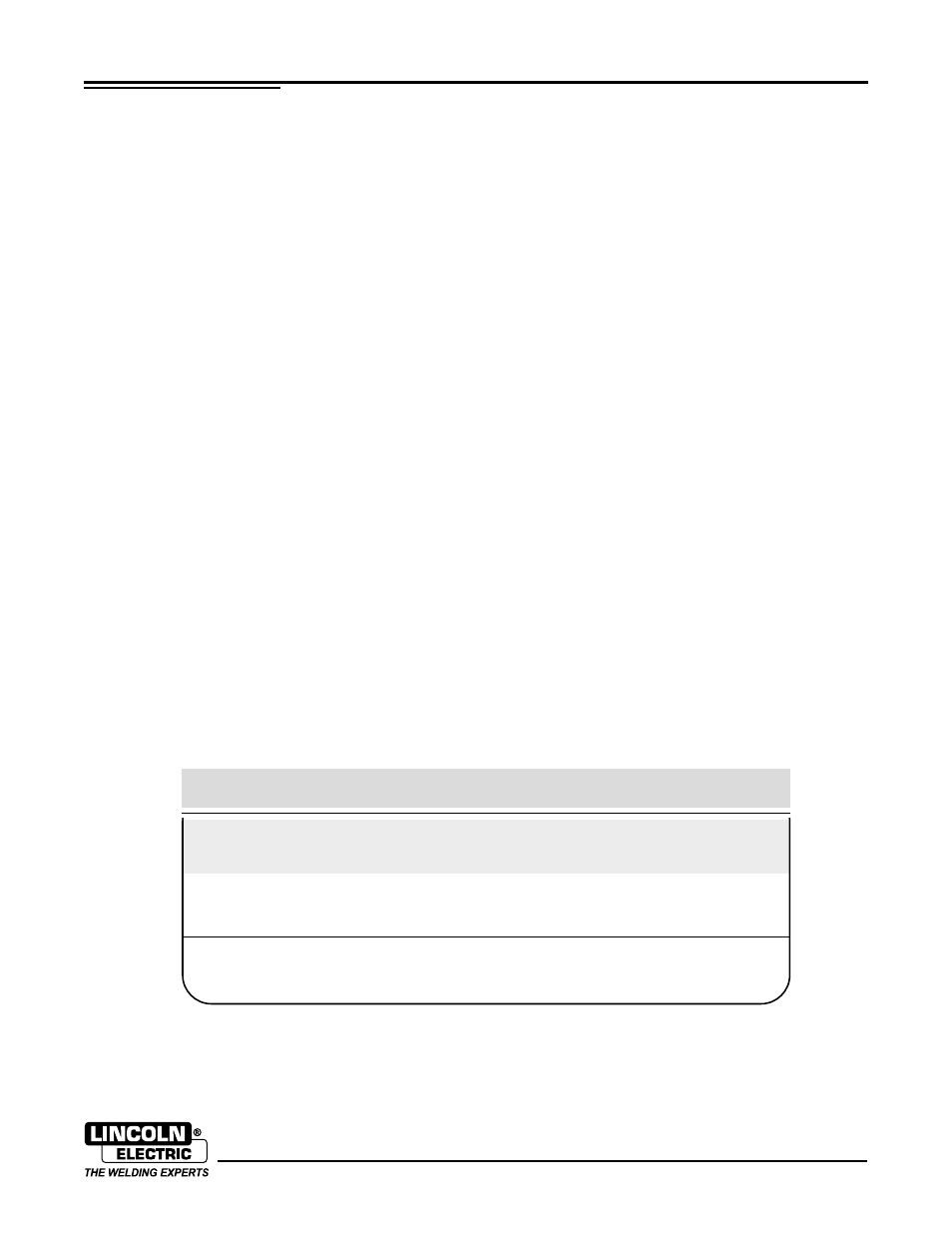

Charpy V-Notch

Charpy V-Notch

Charpy V-Notch

Charpy V-Notch

Flux/Wire

ft•lbf (Joules)

ft•lbf (Joules)

ft•lbf (Joules)

ft•lbf (Joules)

Combination

@ 0ºF (-18ºC)

@ -20ºF (-29ºC)

@ -40ºF (-40ºC)

@ -60ºF (-51ºC)

Actual Test Results

75

76

87

45

As-welded

(101)

(103)

(117)

(61)

P223/L-61

Actual Test Results

113

101

99

82

As-welded

(153)

(136)

(134)

(111)

P223/L-70

MECHANICAL PROPERTIES

(1)

–

Two-pass seam weld on 0.688" wall X-65 pipe

AC/AC two-wire tandem arc procedure

(1)

Mechanical property results obtained on single pass or two-pass welds will vary with base plate composition,

welding procedure, heat input, etc. These results are shown only to demonstrate the potential for the products

being used.

Tested on Pipe