Lincoln Electric LT-7 User Manual

Page 2

LT-7 Tractor

www.lincolnelectric.com

[2]

A CLOSER LOOK

REQUIRED OPTIONS

PERFORMANCE

• Solid-state control system precisely regulates procedures for

reliable starting and economical welding.

• Automatic compensation for input voltage and tractor loading

variations.

• Function lights built into the solid-state printed circuit boards aid

troubleshooting to minimize down time.

• Cross seam adjuster speeds setup and lets operator track

irregular joints while welding. Adjustment range is 3-1/8 in.

(79 mm) with clamp and 2-1/2 in. (63 mm) with handwheel.

• To perform a curved weld, the minimum diameter can be as small

as 10 ft. (3.0m) for an inside weld and 13 ft. (3.9m) for an outside

weld.

• To perform an inside circumferential weld, the minimum inside

diameter that can be welded is approximately 5 ft. (1.5m).

QUALITY AND RELIABILITY

• Three-year warranty on parts and labor.

• Manufactured under a quality system certified to ISO 9001

requirements.

• Rugged and durable design recognized throughout the industry

for its long life and years of trouble-free wire feeding.

FEATURES

• Quick, easy installation of optional guides for different joints.

• Reel holds 60 lb. (27.2 kg) solid wire coils.

• Flux hopper capacity of 15 lbs. (6.8 kg). Includes a manual flux

flow rate control valve and can be mounted at four locations to

the left or right.

• Continuous Vertical Adjustment: 1-1/2” (38 mm) handweel

variation for ESO (electrical stickout).

• Travel clutch operates from either side of the tractor.

4

5

6

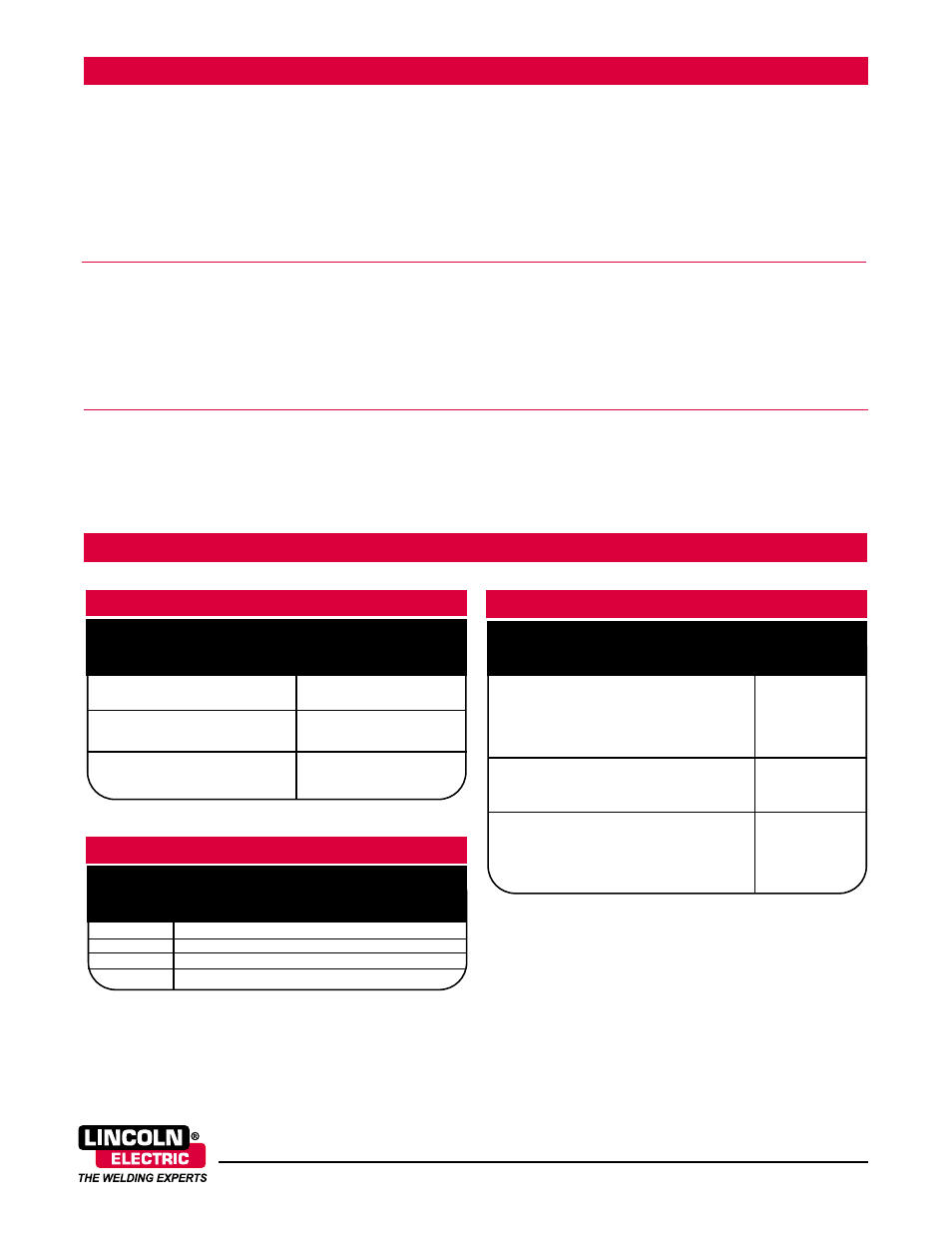

WELD POWER CABLES

CONTROL CABLES

Description

Order No.

Wire Feeder Control Cable

K1822-25 - 25 ft. (7.6m)

Wire Feeder Control Cable Extensions

K1797-25 - 25 ft. (7.6m)

K1797-50 - 50 ft. (15.2m)

Adapter Cable for Control Cable

K1798

to Terminal Strip Power Sources

Order No.

Description

K1842-10

Lug to Lug, 3/0, 600A, 60% duty cycle, 10 ft. (3.0m)

K1842-35

Lug to Lug, 3/0, 600A, 60% duty cycle, 35 ft. (10.6m)

K1842-60

Lug to Lug, 3/0, 600A, 60% duty cycle, 60 ft. (18.2m)

K1842-110

Lug to Lug, 4/0, 600A, 60% duty cycle, 110 ft. (33.5m)

4

5

6

CONTACT NOZZLE ASSEMBLIES

Description/Diameter Wire

Order No.

Submerged Arc:

3/32” (2.4 mm)

K231-3/32

1/8” (3.2 mm)

K231-1/8

5/32” (4.0 mm)

K231-5/32

3/16” (4.8 mm)

K231-3/16

Positive:

3/32 - 1/8” (2.4 - 3.2 mm)

K148A

3/32 - 3/16” (2.4 - 4.8 mm)

K148B

Linc-Fill™ Attachments for Positive Contact Nozzle Asbly

Extension for K148

3/32” (2.4 mm)

K149-3/32

1/8” (3.2 mm)

K149-1/8

5/32” (4.0 mm)

K149-5/32