Operation, Controls and settings – Lincoln LN-742H User Manual

Page 16

B-2

OPERATION

B-2

•

0.045 to 5/64 in. (1.2 to 2.0 mm) cored wire for

Innershield processes.

The LN-742H is capable of the following wire feed

ranges:

•

0.025 to 0.045 in. (0.6 to 1.2 mm) solid wire for gas-

metal-arc or CV submerged arc processes.

•

0.035 to 0.045 in. (1.2 mm) cored wire for

Outershield, Metalshield or Innershield processes.

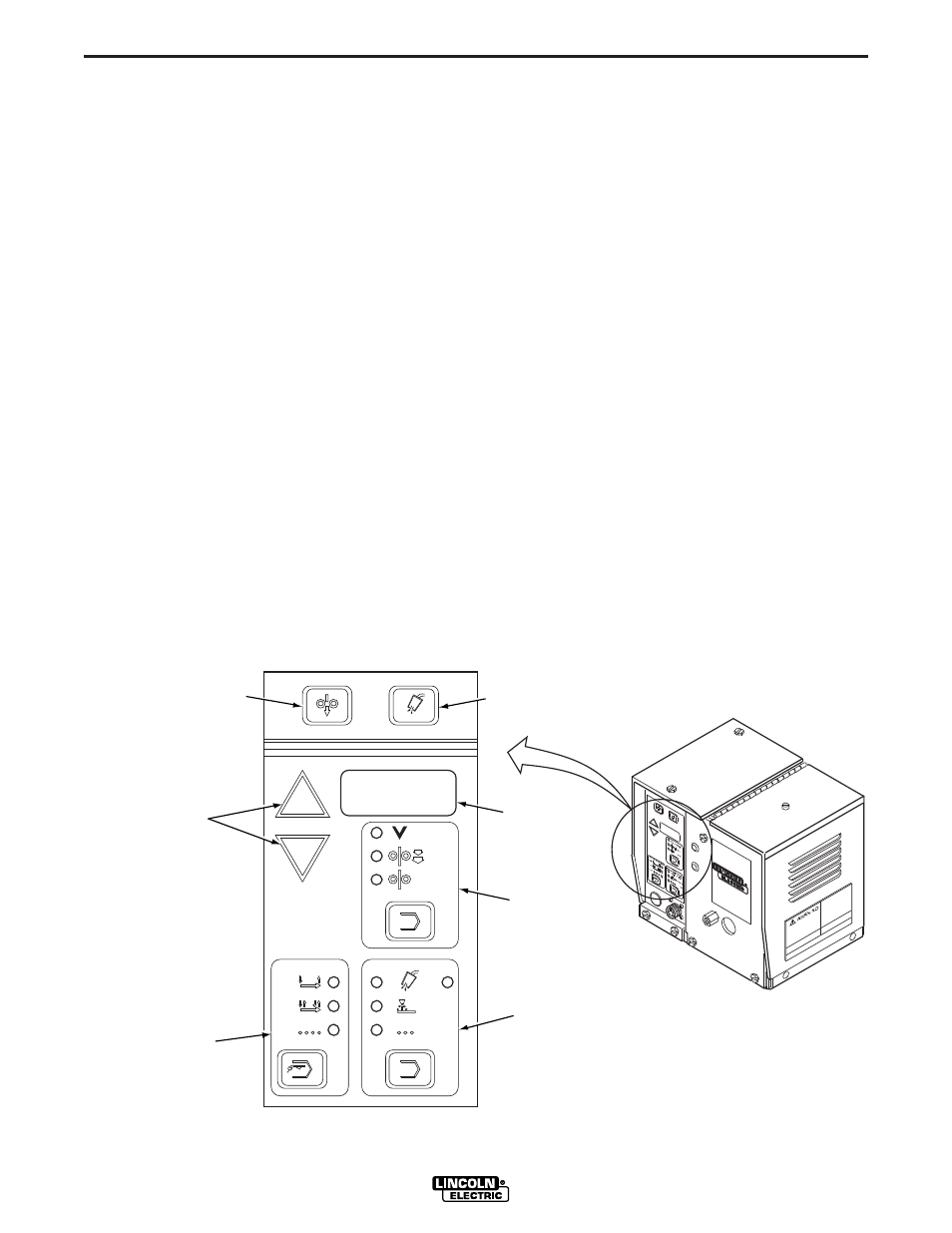

CONTROLS AND SETTINGS

The operator controls are located on the keypad

shown in Figure B.1. The keypad consists of: 7

membrane keys with tactile-feel embossed domes,

that are generously spaced to provide easy selection,

even while wearing welding gloves; a long-life, 3-1/2

digit, 7 segment LED display with 0.56 in. (14.2 mm)

character height, permitting easy viewing even from

long gun cable distances; and high intensity, red, LED

indicator lights that allow for viewing at almost any

angle.

TRIGGER MODE CONTROLS. This control enables

the operator to choose the mode of operation as

shown by the indicator lights. Pressing the key causes

the mode lights to sequence (from top to bottom).

The top light indicates standard (two-step) trigger

mode. In this mode the unit will only be active when

the trigger is pressed. The middle light indicates lock

(four-step) trigger mode. In this mode the solenoid is

energized when the trigger is pressed, the power

source and wire feeder are energized after preflow

time when the trigger is released. Closing the trigger a

second time turns off the wire feeder and then the

power source after burnback time. Releasing the

trigger a second time turns off the solenoid after

Burnback time. The bottom light indicates spot weld

trigger mode. Closing the trigger allows a single,

timed, weld cycle. The duration of the weld cycle is set

with the time selection controls. The spot on timer

starts when welding current flows.

TIME SELECTION CONTROLS. This control enables

the operator to choose which timer will be displayed

as shown by the indicator lights. Pressing the key

causes the mode lights to sequence (from top to

bottom). Any timers not available to the currently

selected mode will be skipped. Times displayed in the

LED display are adjusted using the setting adjustment

arrows to the left of the LED display. The top left light

indicates the preflow time is being displayed in

seconds. The top right indicator light indicates the

postflow time is being displayed in seconds. The

middle light indicates the burnback time is being

displayed in seconds. The bottom light indicates the

spot weld time is being displayed in seconds.

LN-742 & LN-742H

COLD INCH

OLTMETER

INCH

WFS

PREFLOW

POSTFLOW

BURNBACK

SPOT

STD

LOCK

SPOT

TIME

TRIGGER MODE

t1

t2

GAS PURGE

t

t

t

GAS

PURGE

KEY

LED

DISPLAY

FUNCTION

SELECTION

CONTROLS

TIMER

SELECTION

CONTROLS

SETTING

ADJUSTMENT

ARROW KEYS

TRIGGER

MODE

CONTROLS

COLD

INCH

KEY

FIGURE B.1

–

WIRE FEEDER CONTROLS.