Locke TVM-3077 User Manual

Page 11

NOTE:

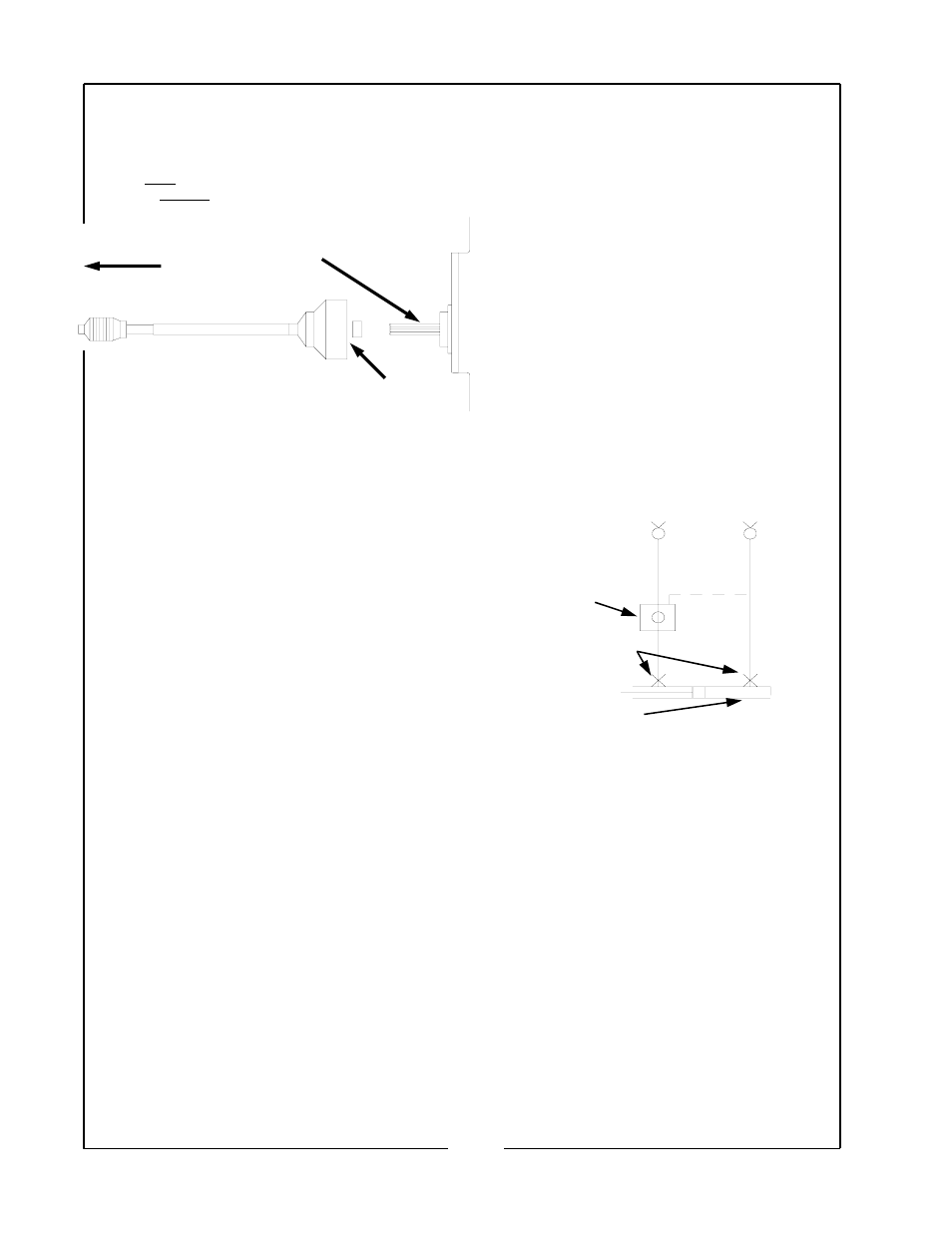

The “lift” hose runs into the port on the front of the check

(lock) valve.

The large (constant velocity U-joint) end of the shaft goes

on the tractor’s PTO shaft.

Belt Idlers – Main Drive

Check regularly for correct belt tension, particularly every 5

to 10 hours following installation of new belts. To adjust

belt idlers:

1. Remove belt guards.

2. Loosen idler clamping bolt.

3. Adjust idler to allow 3/4" to 1” up and down movement

of the bolt half way between sheaves.

4. Replace bolt guards.

Lift Chain Adjustment

The outer lift chains on mowing units #4 and #5 provide

adjustment of the nylon rollers in the snubbers and lift op-

eration. IF the #4 and #5 mowing units do not engage the

snubber ramps properly when lifting, adjust as follows:

1. Lower cutting units to the ground and loosen the nut

on the chain-adjusting rod and back off the nut several

turns.

2. Remove the clevis pin form the adjusting yoke.

3. Turn the adjusting yoke towards the nut to increase the

lift and decrease the roller clearance in the snubber.

4. Replace the yoke and clevis pin, making sure that the

chain is not twisted.

5. Lift the mowing units into place to check that adjust-

ment is correct when there is slight tension on the lift

chain and the nylon rollers are tight in the snubber.

6. When adjustment is correct, tighten the adjusting rod

locking nt. Insure also that the cotter pin is secure.

Cutting Unit Belt Adjustment

The cutting units on the Verti-Cutter are equipped with

heavy duty spring tensioning. For proper operation the

belts must be extremely tight. Tighter than is normally

recommended in other belt drive applications. Keep the

spring at no more than 2" in total length with the unit in

operating position and this should provide ample tension to

the belt. It will be necessary to check the spring length and

make recommended adjustments every 2 - 3 hours or as

needed. See diagram on page 16 of this manual.

Rear units will not climb onto snubbers:

PROBLEM

SOLUTION

1. Insufficient hydraulic

See tractor

Pressure

manual

2. Mechanical interference

Check to see that

no

moving

parts,

chains,

etc.

are

trapped

and

locked.

Units will not stay in raised position:

PROBLEM

SOLUTION

1. Leakage from hose

Tighten fittings.

Between check valve

replace fittings or

And cylinder

hose if necessary

replace

cylinder

seals.

Replace

cylinder if

necessary.

2. Leaking check

Replace check

valve

valve

Hydraulic

Plumbing

To lower the cutting units:

1.

Make sure the transport safety chain is un-

hooked and stowed on the left rear lift arm.

IMPORTANT:

DO NOT ATTEMPT TO LOWER THE CUTTING

UNITS WITH THE TRANSPORT SAFETY

CHAIN IN PLACE, AS THIS MAY RESULT IN

DAMAGE TO THE LIFT SYSTEM.

2.

Place the tractor’s external hydraulics control

valve in the “lower” position. Return the valve to the

center (neutral) position when the rear cutting unit lift

arms are fully down.

To raise the cutting units:

1.

Place the tractor’s control valve in the “lift”

position. Return the valve to the center (neutral) posi-

tion when the rear outer cutting units have fully en-

gaged snubbers.

Mower

Tractor PTO Shaft

Constant Velocity

U-Joint

Check (Lock)

Valve

Restrictor

Lift Cylinder

Pilot

Line

Pressure To

Lift

Pressure To

Lower

9