Troubleshooting, Caution – Lincoln Electric MAGNUM PCT125M User Manual

Page 19

D-4

TROUBLESHOOTING

D-4

PLASMA TORCH

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local

Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

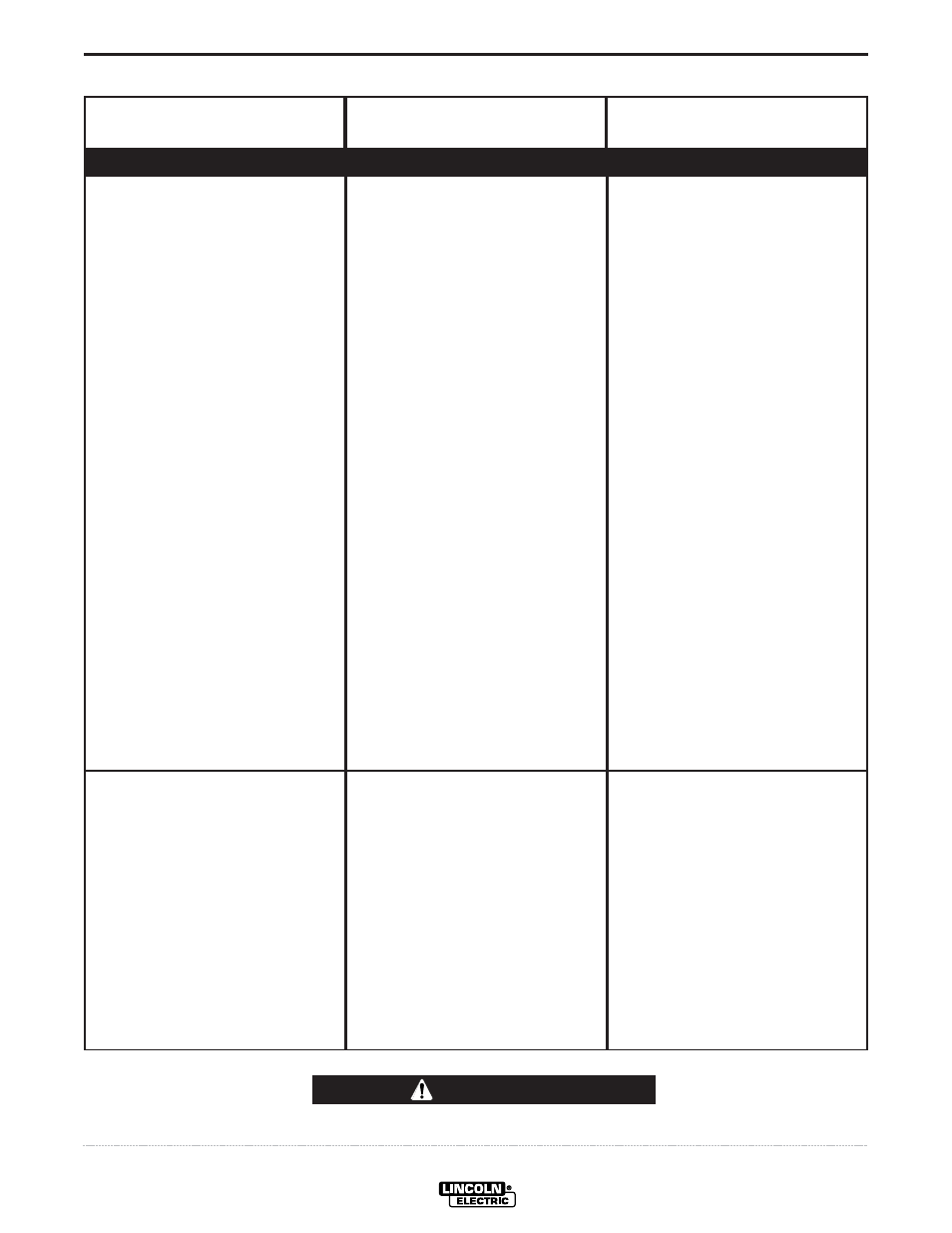

FUNCTION PROBLEMS

PROBLEMS

(SYMPTOMS)

POSSIBLE CAUSE

RECOMMENDED

COURSE OF ACTION

Only a brief spurt of a Pilot Arc

appears

Electrode Stuck in Torch head

a. Make sure the air pressure is

set correctly

b. Consumables may be improper-

ly assembled.

c. There may be oil in the air.

d. The Pro-Cut may be in expand-

ed metal mode.

e. The swirl ring may have holes

out of spec.

f. The Pro-Cut is not working prop-

erly.

a. The duty cycle may have been

exceeded

b. Make sure the Pro-Cut has the

larger solenoids (this applies to

codes 10097 and lower only)

c. Make sure the air pressure is

set properly.

a. Put the Pro-Cut in Purge and

adjust the air pressure to 55-65

psi while the air is flowing.

b. Make sure an electrode, swirl

ring, nozzle and shield cup are

assembled in the torch.

c. Check the filters in the regula-

tors for oil. Replace if neces-

sary and eliminate the source of

oil.

d. This is a normal condition which

occurs after several long pilot

arcs have been pulled in a row.

After a while, the Pro-Cut will

return to the standard pilot arc if

no pilot arcs are pulled for sev-

eral seconds.

e. Some swirl rings were shipped

with the swirl hole diameter too

large. If possible, use plug

gages to make sure the swirl

hole diameter is not larger than

.028”.

f. Refer to the troubleshooting

guide for the Pro-Cut 125.

a. Operate the Pro-Cut within the

duty cycle limits (125 Amps at

60%, 100 Amps at 100%.)

b. Install a S21237 solenoid kit.

c. Put the Pro-Cut in Purge and

adjust the air pressure to 55-65

psi while the air is flowing.