Air resistance, Repair parts, Wiring diagrams – Lennox International Inc. 505 User Manual

Page 13

Page 13

EDA INSTALLATION/ SERVICE INSTRUCTIONS

Air Resistance

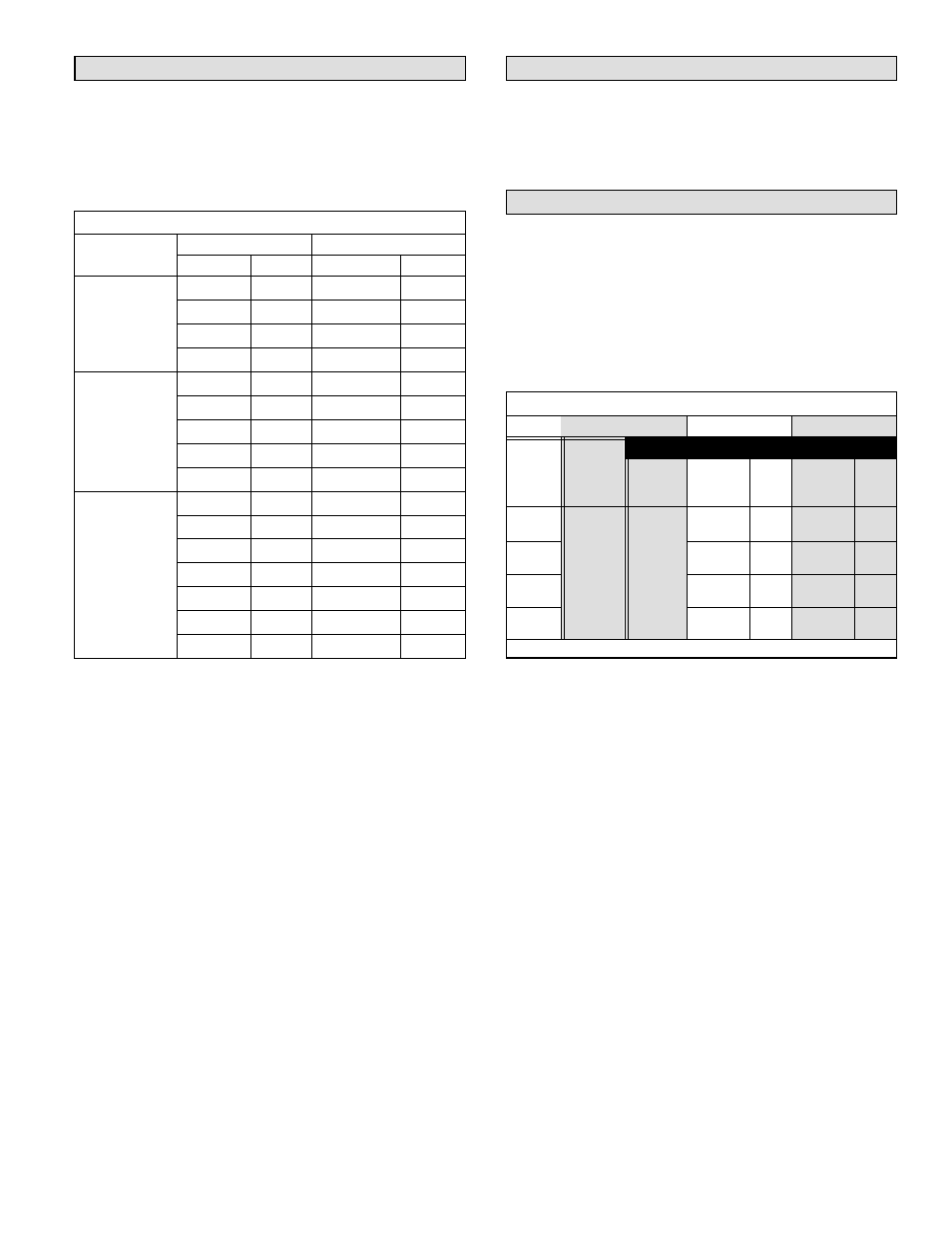

Table 2 shows air volume and total air resistance for the

available EDA models.

Table 2

Air Resistance

Air Volume

Total Air Resistance

Model No.

cfm

L/s

in. w.g.

Pa

EDA−024B

400

190

0.05

12

600

285

0.10

25

800

380

0.15

37

1000

470

0.22

55

EDA−036C

600

285

0.05

12

800

380

0.08

20

1000

470

0.11

27

1200

565

0.15

37

1400

660

0.20

50

EDA−060DB

1000

470

0.05

12

1200

565

0.06

15

1400

660

0.08

20

1600

755

0.10

25

1800

850

0.11

27

2000

945

0.13

32

2200

1040

0.15

37

Repair Parts

S

3−way diverting valve assembly

S

Check/flow restrictor

S

EDA Relay

S

Outdoor unit relay

S

Teflon seals

Wiring Diagrams

Typical condensing unit and heat pump wiring diagrams

are provided in figures 12 and 13. Some modifications to

certain units may be necessary.

Connect the EDA unit with the indoor and outdoor units,

and to the thermostat. Be sure the outdoor sensor is

installed and connected to the SignatureStat

t thermo-

stat’s outdoor sensor terminal block. Table 3 shows the re-

quirements for control wiring.

Table 3

Control Wiring Requirements

Units:

(all)

(with LSOM)

(without LSOM)

Signa-

Indoor unit to:

System

type

Signa-

tureS-

tat

t to

Sensor

Humidi-

trol®

EDA

Signatu-

reStat

t

Out-

door

unit

Signatu-

reStat

t

Out-

door

unit

2 stage

AC

9*

6

8*

4

1 stage

AC

2

(twisted

3

8*

5

7*

3

2 stage

HP

(twisted

pair)

3

10*

8

9*

7

1 stage

HP

9*

7

8*

6

*Includes conductor for 2−stage heat