English, Periodic maintenance – KTM 450 SX User Manual

Page 23

ENGLISH

22

PERIODIC MAINTENANCE

»

250 SX-F 2006

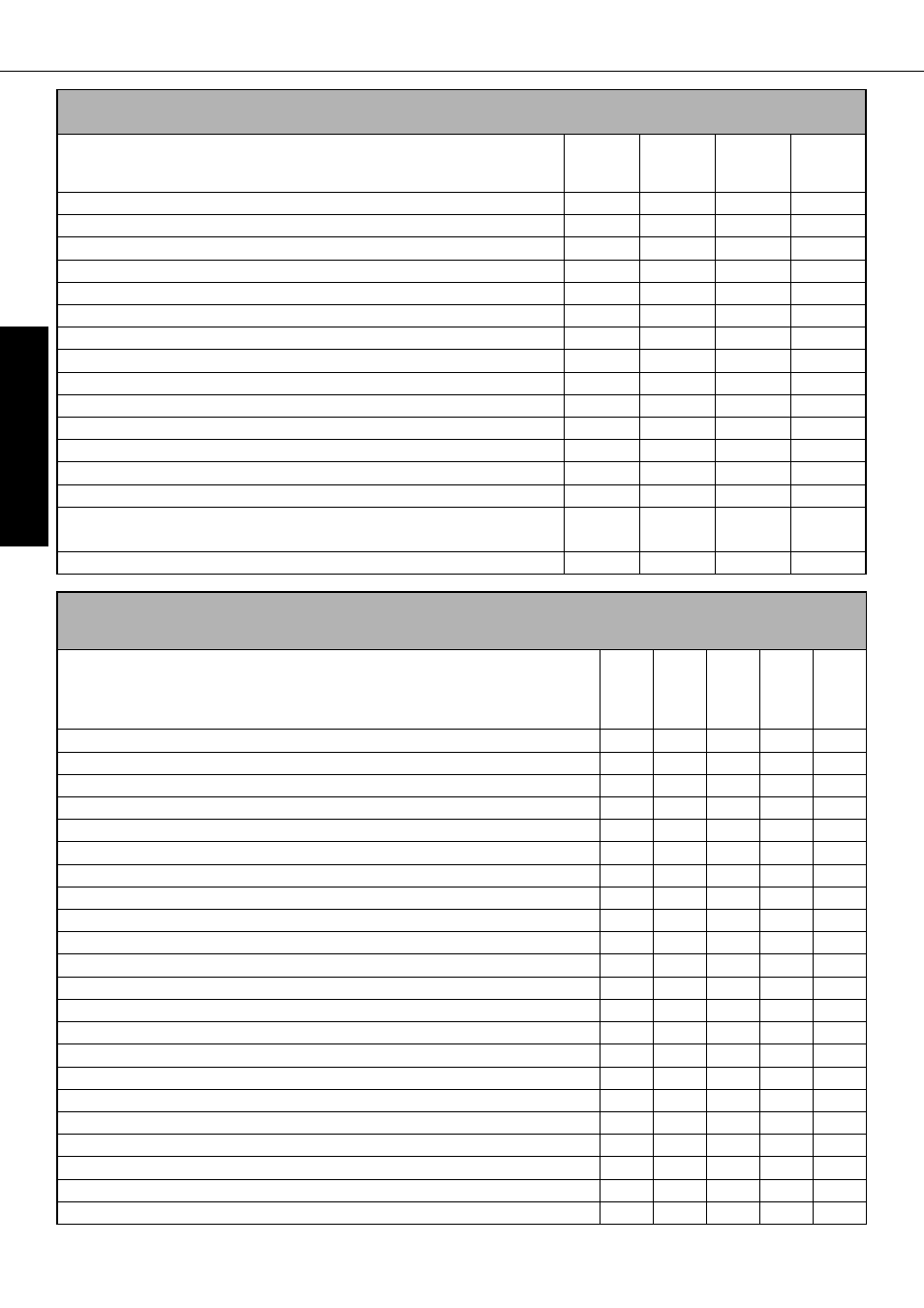

IMPORTANT CHECKS AND MAINTENANCE TO BE CARRIED OUT BY THE RIDER

Before

each

start

After

every

cleaning

For cross-

country

use

at least

once

a year

Check oil level

z

Check brake fluid level

z

Check brake pads for wear

z

Lubricate and adjust cables and nipples

z

Bleed fork legs regularly

z

Remove and clean fork dust bellows regularly

z

Clean and lubricate chain, check tension and adjust if necessary

z

z

Clean air filter and filter box

z

Check tires for pressure and wear

z

Check cooling fluid level

z

Check fuel lines for leaks

z

Drain and clean float chamber

z

z

Check all control elements for smooth operation

z

Check brake performance

z

z

Treat blank metal parts (with the exception of brake and exhaust system)

with wax-based anti corrosion agent

z

Check tightness of screws, nuts and hose clamps regularly

z

250 SX-F 2006

RECOMMENDED INSPECTIONS OR MAINTENANCE WORK BY THE AUTHORIZED KTM WORKSHOP FOR COMPETITIVE RACING

(ADDITIONAL ORDER FOR THE KTM WORKSHOP)

A 100 liter fuel consumption is equivalent to approx. 15 operating hours

every

10

hours

70

liter

every

20

hours

140

liter

every

40

hours

270

liter

every

60

hours

400

liter

every

80

hours

540

liter

Check the clutch disks for wear

z

z

z

z

Check the length of the clutch springs

z

z

z

z

Check the clutch drive for indentations

z

z

Check the outer clutch hub for indentations

z

z

Check the cylinder and piston for wear

z

z

Check the groove on the piston pin retainer for wear (visual check)

z

z

Check the camshaft for wear (visual check)

z

z

Check the spring cap for wear

z

z

Check the eccentricity of the valve disk

z

z

Check the valve guides for wear

z

z

Replace the valves

z

Replace the valve springs

z

z

Check the function of the chain tensioner

z

z

Check the eccentricity of the crankshaft journal

z

z

Replace the conrod bearings

z

z

Check piston pin bearing

z

z

Replace the crankshaft main bearings

z

Check the entire transmission including the roller and bearings for wear

z

z

Check the length of the bypass valve spring

z

z

Replace the glass-fiber yarn filling in the silencer

z

z

z

z

z

Replace the sealing cup for the foot brake cylinder

z

z

z

z

z

Replace the throttle slide, jet needle and main jet holder (every 200 hours)

NOTE:

If the inspection establishes that permissible tolerances are exceeded, the respective components must be replaced.