Operation #2 re-assembly – Keating Of Chicago Flexible Tubing to Hard Piping 055173 User Manual

Page 2

FLEXIBLE TUBING to HARD PIPING INSTALLATION

INSTRUCTIONS - for MOTOR/PUMP PART# 055173

(CONTINUED)

p a g e 2

h a r d P i p i n g 0 57 1 2 2 . q x d

1 0 / 0 9

Operation #2 Re-Assembly

Your Kit Includes (items with * may not be included):

Item

Part #

Qty

Description

A

---------

-

------------------------

*B

056990

1

Pipe Nipple 3/8 NPT 1-1/2 SS-304

C

056907

1

Bracket Ass’y Haight Baker Pump

D

020101

8

Nut 5/16 Hex Head Serrated Flang

E

017142

4

Screw 5/16-18 x 3/4 Hex Head

F

015227

2

Nut 1/4” Acorn S/S

G

004611

4

Screw #10 x 3/8 Sheet Metal Pan HD.

*I

037672

A/R

Sealant Locktite 262 (.017 oz.)

J

056765

8

Washer Flat 7/16” ID x 1.00 OD x .078 THK.

K

017481

4

Screw 5/16 -18 x 1-3/4 Hex HD SS

L

X

1

Reinforcement Bracket

M

015158

2

Acorn Nut 5/16-18 SS

N

052733

2

Washer 11/32 ID x 3/4 OD

O

000290

2

Washer, Lock 5/16” Spilt

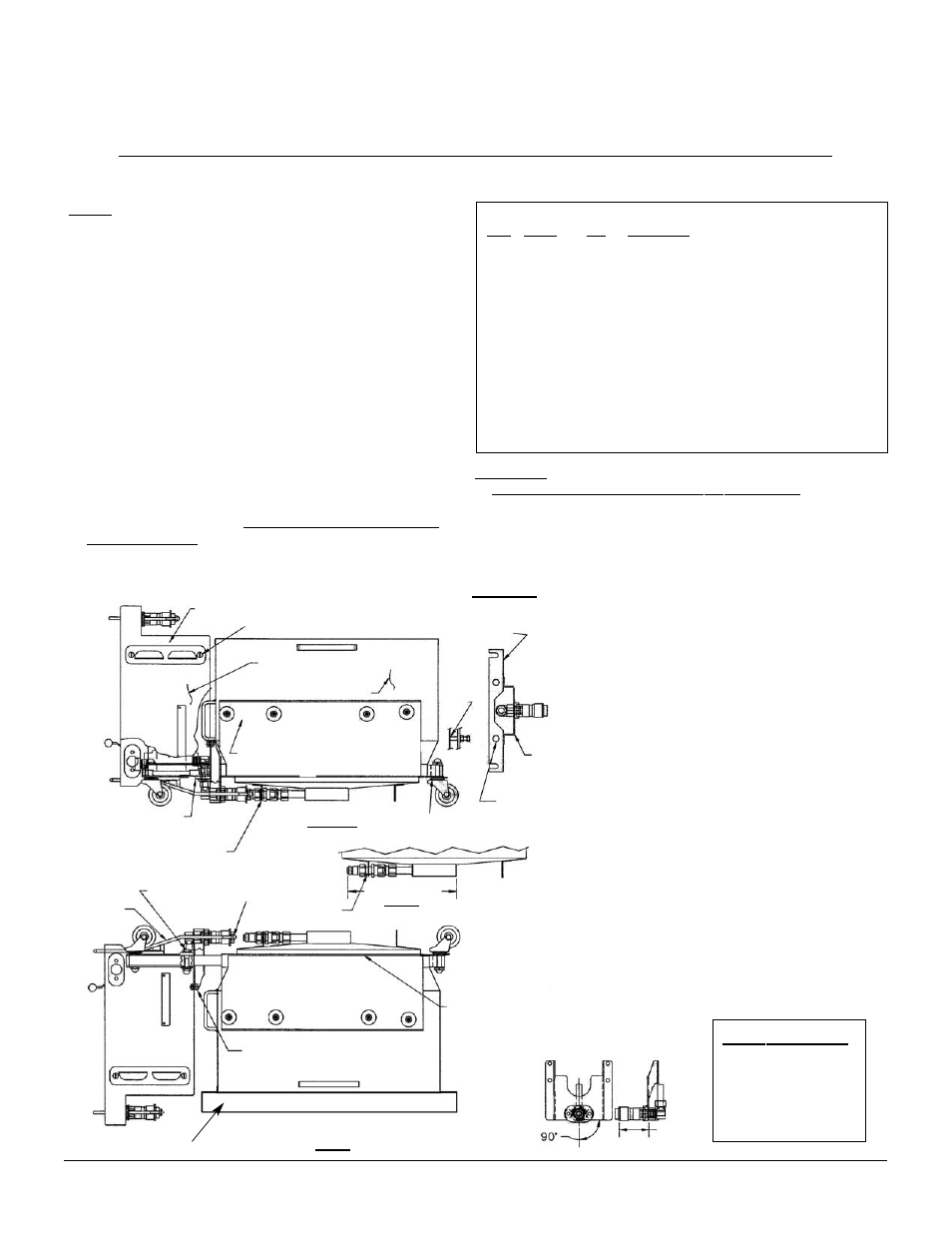

Pump Mount Cover

G See Note #4

Motor Mount Housing Assembly

Filter Tub Assembly

Filter Cart Frame Assembly

L

See Note #2

See Note #1

Filter Tub Connected

Side View

Bottom View

Mount Reinforcement

Bracket as Shown

Bolts

Must Be

Flush Not

Tight

C

K&D Bolts Only

for Models 20”

and 24” See

Note #2

J&I See

Note #5

Filter Tub

Pull Rod

See Note #3

K,M,N,O

F&I See

Note #3

B

D&E

Support Filter Tub As

Shown to Remove Any

Play Between Tub and

Filter Cart.

Item ‘C’ Detail

Filter Tub Disconnected

View B

See Note A

View A

Table or Bench

2-5/8”

Note A Dimensions

9-5/16” for 14” Filter

11-3/8” for 18” Filter

12-3/8” for 20” Filter

14-3/8” for 24” Filter

Notes:

1. Remove filter tub from motor/pump housing assembly and

set aside. On 18, 20 and 24 models only, remove pipe nipple

3/8” NPT x 1” and discard. Replace with pipe nipple 3/8”

NPT x 1-1/2” (item B). See view A for proper dimensions

from back of sump to front of quick connect. On 14” filter tub,

see view A for proper dimesions from back of sump to front

of quick disconnect. Place the filter tub into the filter cart

assembly. Release the filter tub away from the pump housing

as shown in side view. Turn the entire assembly upside down

as shown in view B. This step is critical to insure proper

alignment between the motor housing quick connect and the

filter tub quick connect. Use table or bench, making sure the

motor/pump housing is off of the table/bench.

CAUTION: IF FILTER ASSEMBLY IS PLACED UPSIDE DOWN

ON A TABLE OR BENCH, MAKE SURE UNIT IS SECURE, SO

AS NOT TO SLIDE OFF TABLE/BENCH.

2. Slide item C into position to connect the compression fitting

on the pump’s 90° fitting. DO NOT TIGHTEN COMPRES-

SION FITTING AT

THIS TIME. Attach item C, to the pump housing with items D and

E. DO NOT TIGHTEN COMPLETELY AT THIS TIME. Play must be

present for proper alignment of pump housing connect and filter

tub quick connect. Slide the filter tub assembly forwarduntil the

quick connects are engaged. Tighten items D and E completely.

Tighten compression on item C. Remove (2) bolts and washers “K”

and add reinforcement bracket “L.” Use longer (2) bolts provided

and discard old ones. For 20 and 24 models, add

items D and K to reinforcement bracket and

tighten until snug on motor mount housing

assembly (See Bottom View).

3. Attach filter tub pull rod handle using item

F and I.

4. Attach the pump mount covers using item G.

5. Inspect for spacers between casters and filter

cart assembly. If none are present, remove

casters and place item J (2) on the casters

threaded stem and reassemble using existing

fasteners and item I.

6. Carefully turn filter assembly to the upright

position. Release the filter tub pull rod and

check for proper disconnect. Reconnect the

filter tub to the motor mount housing using

handles. If the assemblies do not connect

properly, it will be necessary to verify notes

above were followed correctly.

7. Fill filter tub with oil per users manual, cycle oil

to check for leaks at fittings, correct if needed.

L