Maintenance schedule – Kohler Command CH620 User Manual

Page 9

9

• Replace fuel filter

1

(EFI engines).

Daily or Before

Starting Engine

Maintenance Required

Frequency

• Fill fuel tank.

• Check oil level.

• Check air cleaner for dirty

1

, loose, or damaged parts.

• Check air intake and cooling areas, clean as necessary

1

.

• Service precleaner element

1

.

Every 25 Hours

• Replace air cleaner element

1

.

• Change oil. (More frequently under severe conditions.)

• Remove cooling shrouds and clean cooling areas

1,3

.

• Check oil cooler fins, clean as necessary (if equipped).

• Check spark plug condition and gap.

• Change oil filter.

• Replace fuel filter (carbureted engines).

Annually or

Every 500 Hours

• Have bendix starter drive serviced

2,4

.

• Have solenoid shift starter disassembled and cleaned

2,4

.

Every 100 Hours

Every 200 Hours

Every 1500 Hours

1

Perform these maintenance procedures more frequently under extremely dusty, dirty conditions.

2

Have a Kohler Engine Service Dealer perform this service.

3

Cleanout Kits 25 755 20-S (black) or 25 755 21-S (gold) allow cooling areas to be cleaned without removing shrouds.

4

Only required for Denso starters. Not necessary on Delco starters.

• Have crankshaft spline lubricated

2

.

Every 500 Hours

Every 250 Hours

• Replace heavy-duty air cleaner element and check inner element

1

.

Check Oil Level

The importance of checking and maintaining the

proper oil level in the crankcase cannot be

overemphasized. Check oil BEFORE EACH USE as

follows:

1. Make sure the engine is stopped, level, and is cool

so the oil has had time to drain into the sump.

2. To keep dirt, debris, etc., out of the engine, clean

the area around the dipstick before removing it.

3. Remove the dipstick; wipe oil off. Reinsert the

dipstick into the tube and press all the way

down.

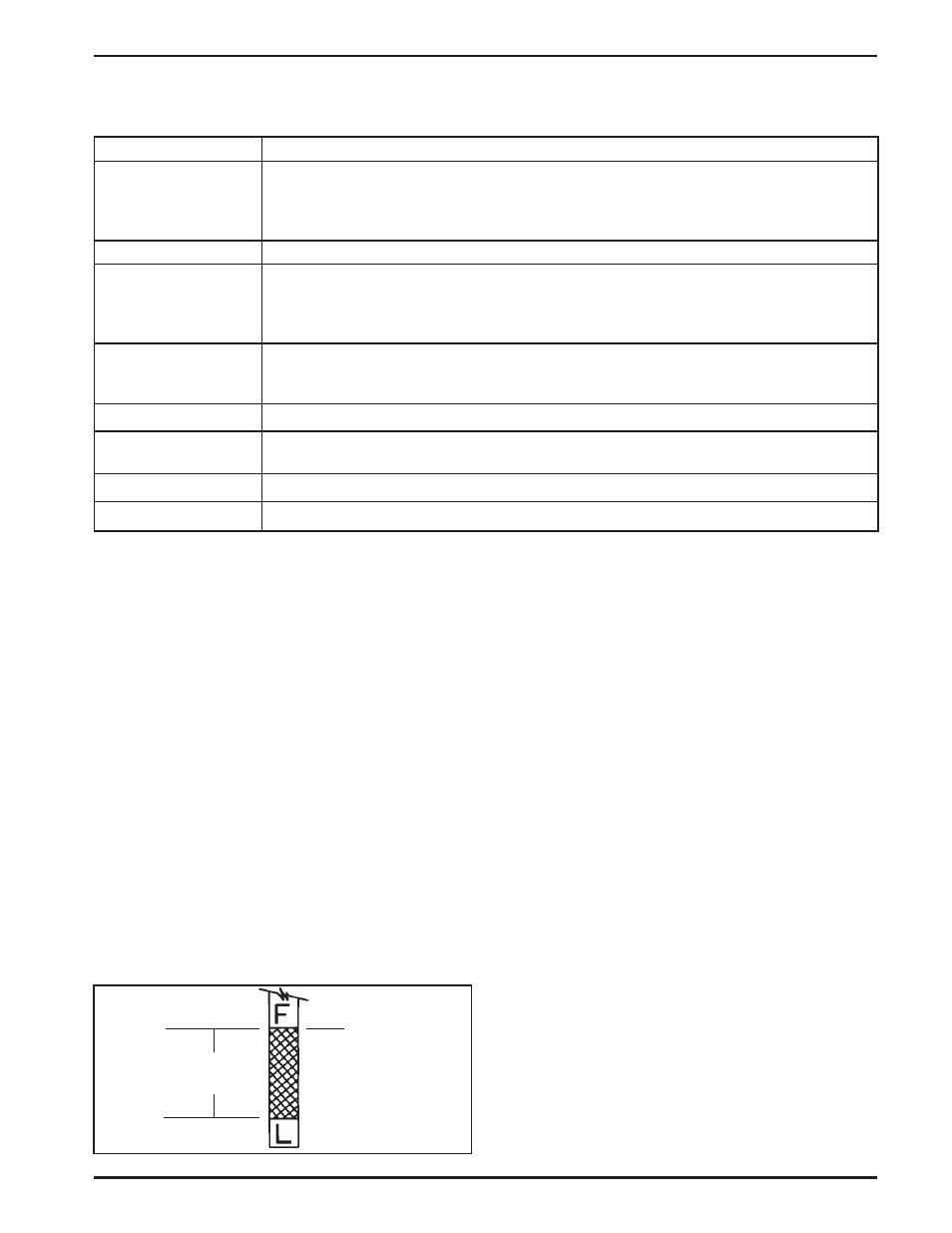

4. Remove the dipstick and check the oil level.

The oil level should be up to, but not over, the “F”

mark on the dipstick. See Figure 7.

5. If the level is low, add oil of the proper type, up to

the “F” mark on the dipstick. (Refer to Oil Type on

page 5.) Always check the level with the dipstick

before adding more oil.

NOTE: To prevent extensive engine wear or

damage, always maintain the proper oil

level in the crankcase. Never operate the

engine with the oil level below the “L”

mark or over the “F” mark on the

dipstick.

Oil Sentry™

Some engines are equipped with an optional Oil

Sentry™ oil pressure switch. If the oil pressure

decreases below an acceptable level, the Oil Sentry™

will either shut off the engine or activate a warning

signal, depending on the application.

NOTE: Make sure the oil level is checked BEFORE

EACH USE and is maintained up to the “F”

mark on the dipstick. This includes engines

equipped with Oil Sentry™.

“F” Mark

Operating

Range

Maintenance Schedule

These required maintenance procedures should be performed at the frequency stated in the table. They should

also be included as part of any seasonal tune-up.

Figure 7. Oil Level Dipstick.