Tips for optimum results, Operations – Woodstock D2796 User Manual

Page 17

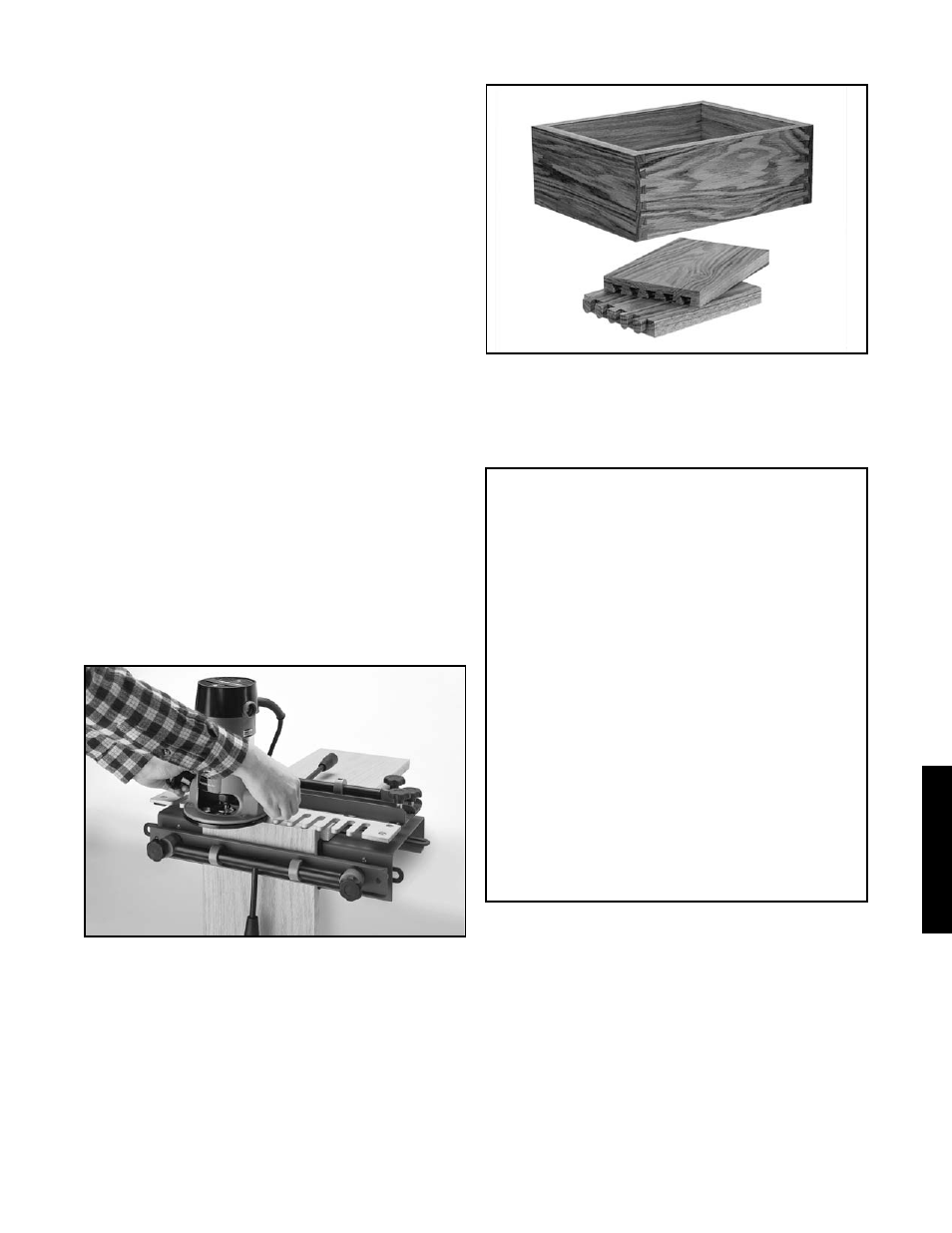

Figure 20 shows a finished drawer

and 2 sides ready to be joined.

Figure 19 shows the dovetail jig in use.

- 15 -

Woodstock Intl., Inc. D2796

OPERATIONS

TIPS FOR OPTIMUM RESULTS

Don’t clamp your work down too tight. Over-clamp-

ing tends to lift the wood on the front side of the jig.

Maintain steady, even pressure on the router when

cutting. Remove materials in several smaller passes,

rather than one large pass. This will lessen the

chances of damaging your project or your router bit.

Use pieces of scrap wood the same thickness as your

workpieces to provide an even base for the template

and clamping mechanisms. Place them at the oppo-

site end of the template and clamps before tightening

the jig.

Be sure the template is sitting flat across the length

of your workpiece before routing to ensure even cut

depth.

Turn the router on and gently ease the bit into the

work, letting the guide bushing gently contact the

template. Facing the dovetail jig, start at your left

side and work to the right, following each template

finger in and out. Ensure that the router base and

guide bushing stay in firm contact with the tem-

plate. See Figure 19.

Hint: If you are using material thicker than

7

/

8

", cut it

in two stages. First, remove the material IN FRONT OF

the fingers. Second, remove the material BETWEEN the

fingers. Use care when the router bit exits the work-

piece to reduce the risk of tear-out.

3.

Remove both pieces from the jig and join the

dovetails. See Figure 20.

4.

It may be necessary to tap the two pieces together

with a hammer and wood block. If alignment is so

poor that the two pieces will not fit together, line

up each piece as much as possible and determine

the direction and degree of fine adjustment.

If the two pieces do not fit, it is usually because they

were not milled square or the pieces were not flush with

each other in the jig.