Regular- maintenance, Lubrication checking tire pressure – Simplicity 1691411 User Manual

Page 13

Regular- Maintenance

LUBRICATION

CHECKING TIRE PRESSURE

A

CAUTION

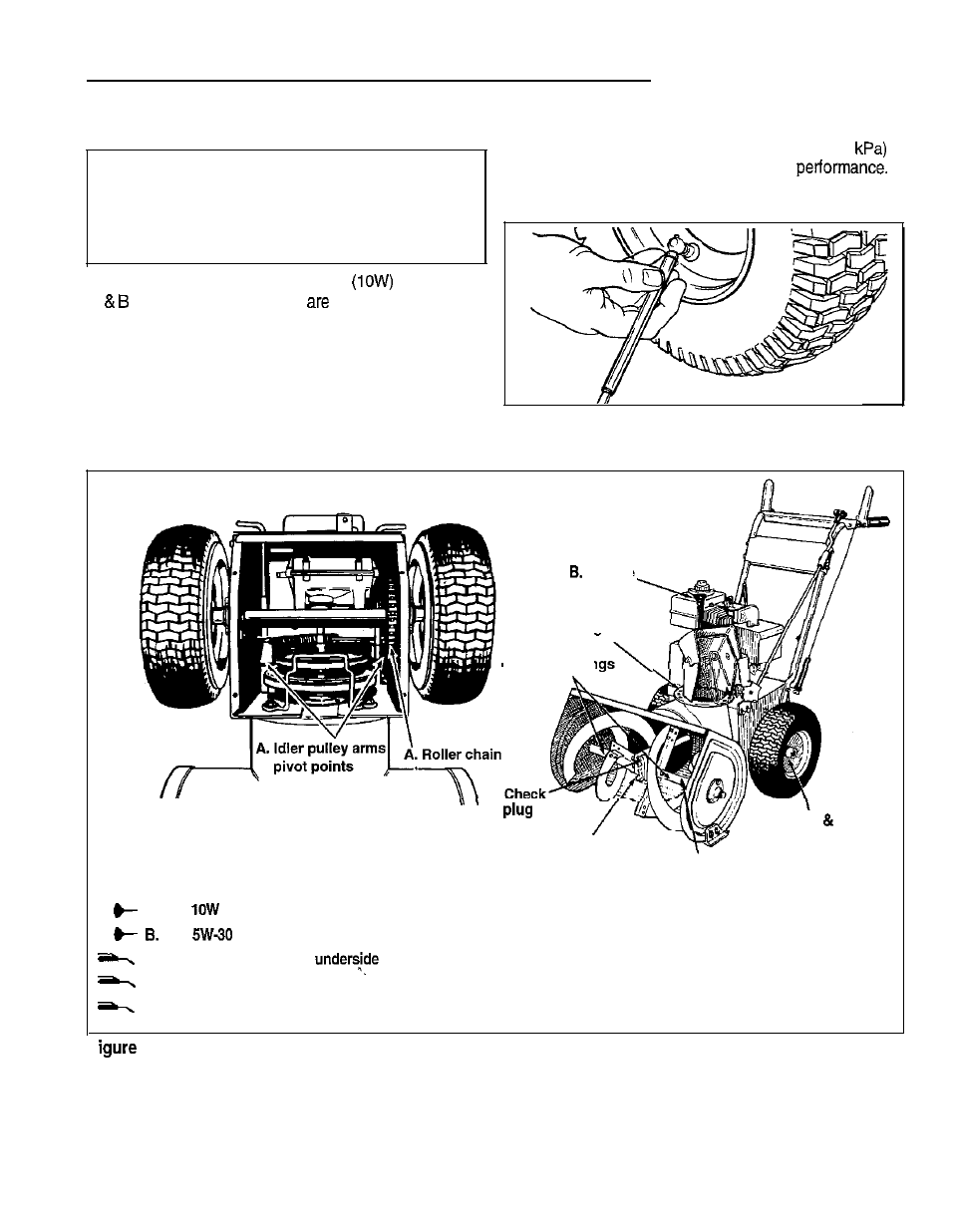

It is very important that grease fittings on auger

shaft (figure 6) are lubricated regularly. If auger

rusts to shaft, damage to worm gear may occur if

shear pins do not break.

With an oil can, apply medium weight

oil to points

A shown in figure 7. There

two grease fittings in

the auger shaft (figure 6). Wipe fittings clean and apply

two or three shots of grease. Also, use grease on other

points shown.

Generally, all moving metal parts should be oiled where

contact is made with other parts. Keep oil and grease off

belts and pulleys.

The air pressure in each tire should be 20 psi (136

and should be equal for both tires for best

Be sure to keep caps on valves to prevent entry of mois-

ture.

I

Figure 8. Checking Tire Pressure

Transmission

Engine

C. Discharge chute

E. Grease fittings

D. Wheeis axles

Auger gear case

Auger shaft

A. Use

oil every 10 hours of use and at beginning of each season.

Add

oil as required. Check engine every 5 hours of use and before each use.

C. Remove chute and coat

of flange with clinging type grease annually.

D. Remove wheels and coat axles with clinging type grease annually.

E. Add grease to two grease fittings annually.

7. Lubrication Points

9