Maintenance – Shindaiwa SP300 User Manual

Page 6

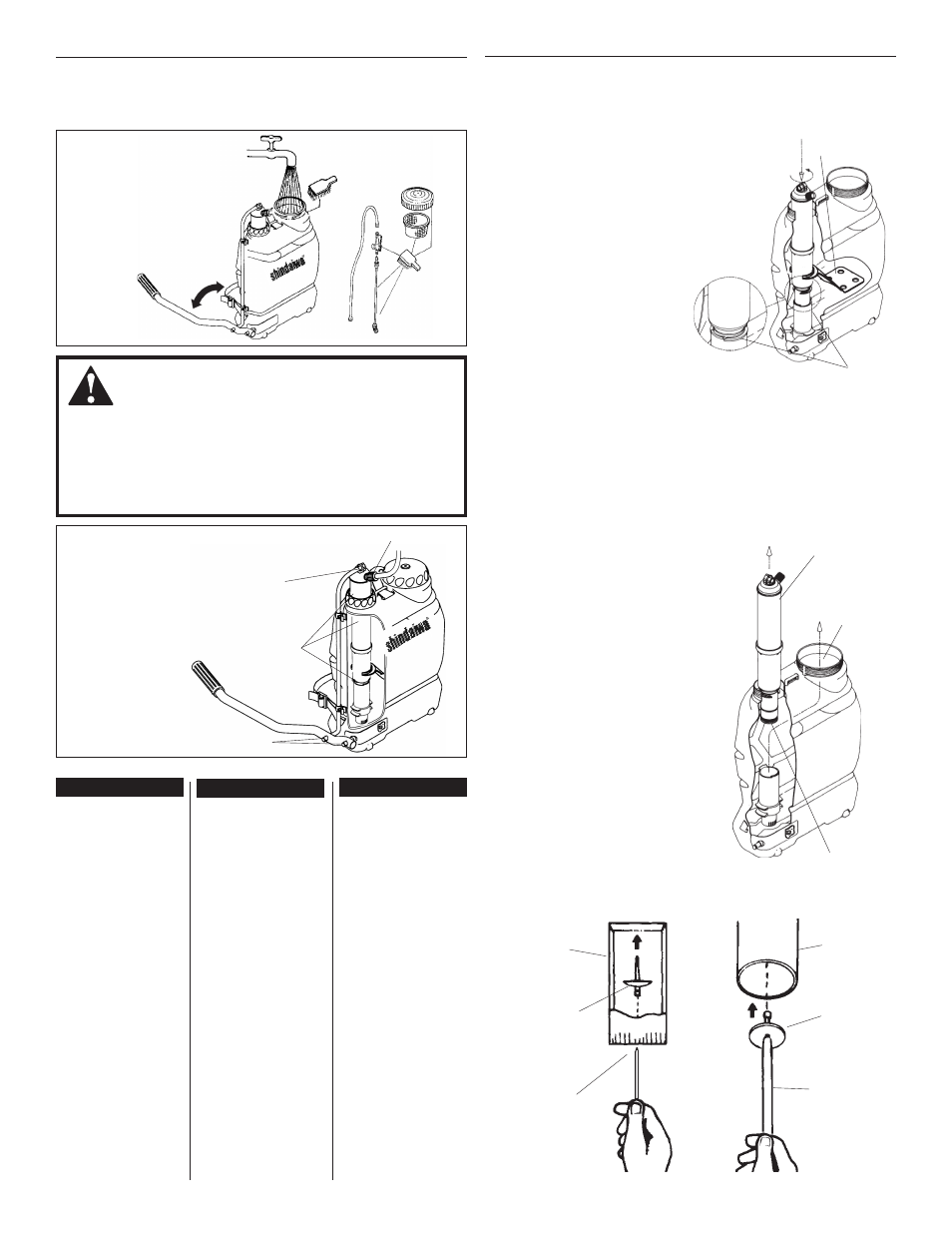

Pump the lever with

the trigger valve open

until the discharge

runs clear

WARNING!

Remove all chemicals and wash before storing the sprayer.

Chemical products have different reactions and can cause

damage to the sprayer components and the environment.

Unidentified chemicals left in the sprayer tank can pose

a serious health threat to anyone servicing the unit and

unaware of its presence!

Periodically clean and

lubricate the pump

chamber, piston cup and

actuating linkage with

a high quality lithium

grease.

Lubricate

(disassembly

required)

Cleaning the Sprayer

After finishing the spray application, empty the sprayer and wash

all equipment in an approved decontamination area.

Relieve all pressure from the pump prior to disassembly or storage.

Maintenance

Troubleshooting: Lack of Pressure

Pump Disassembly

CAUSE

REMEDY

Leakage through

the upper cylinder.

After pumping and

pressurizing the

chamber, the pump

lever drops rapidly

when released.

After pumping and

pressurizing the

chamber, the pump

lever rises slowly

when released.

Low pressure and

pump lever hard to

operate.

Worn or dried out

piston cups.

Cylinder diaphragm

valve not sealing

properly due to

wear or impurities.

Chamber diaphragm

valve not sealing

properly due to wear

or impurities.

Pump chamber

filled with liquid.

Lubricate or replace

the piston cups.

Clean or replace the

cylinder diaphragm

valve.

Clean or replace the

chamber diaphragm

valve.

Tighten screw cap

at top of chamber.

With an empty tank,

pump lever with trig-

ger valve open until

all liquid is purged

from pump.

SYMPTOM

1. Remove the pump-lever connecting rod from the pump

chamber.

2. Remove lid and slide agitator off pump chamber.

3. Loosen the packing ring nut that secures

the chamber to the tank, then push the

chamber into the cylinder all the way

and lock tabs together.

4. Turn the pump chamber 90° to

unlock the cylinder from the tank.

5. Separate the pump cylinder from the

pump chamber and pull the pump

chamber out of the tank.

Remove the cylinder through

the tank fill opening.

6. Remove the piston cup

fastener from the chamber

valve assy. using the 452284

maintenance tool. See page 6.

7. If required, remove cylinder diaphragm

valve with a small screw driver or similar

object as shown in figure below.

8. Clean or replace parts that are

excessively worn.

Assembly

1. Install the diaphragm valve in the

cylinder and secure it using the

installation tool. See figure below.

2. Assemble the piston cup fastener to

chamber assembly.

3. To ease assembly and help prevent

premature wear, lightly lubricate the

piston cup with lithium-base grease.

Insert the cylinder into the tank.

Push the pump chamber into the

cylinder and lock the tabs.

4. Using the pump chamber, place

the cylinder into its location in

the tank. Turn the pump chamber

90°until the cylinder locks in place.

5. Reassemble the pump-lever

connecting rod to the pump

chamber.

6. Tighten the packing ring nut that

secures the pump chamber to the tank.

Push the chamber

into the tank all the

way

Pump Chamber

Assembly

Remove cylinder

through the fill

opening

Grease here

during assembly

Lubricate

Lubricate

Diaphragm

Valve

Cylinder

Installation

Tool

Removal

Diaphragm

Valve

Cylinder

Agitator

Screw Cap