Caution, Vdanger, Tps3 09 installation instructions – Siemens Surge Protective Device TPS3 09 User Manual

Page 5

TPS3 09 Installation Instructions

Pre-Plan your installation. You need to accomplish the following:

• Meet all National and Local codes (NEC

®

Article 285 and UL

1449 address SPDs)

• Confirm System voltage to SPD voltage (120V SPD will fail

instantly on 240V, 277V, etc.)

• Mount SPD as close to panel or equipment as possible to keep

leads short (long leads hurt performance substantially)

• Ensure leads are as short and straight as possible, including

neutral and ground. If using a breaker, use a breaker position

that is close to the SPD and the panel’s neutral & ground

• If using a breaker, recommended breaker size is 30A due to

10 AWG conductor

• Make sure system is grounded per NEC

®

and clear of faults

before energizing SPD (inadvertent system problem may fail

SPD).

• Never Hi-Pot test Any SPD (will prematurely fail SPD)

• Do not install the TPS3 09 through the bottom of a NEMA

3R panel. Dripping water will prematurely fail the SPD.

1. Use voltmeter to check voltages and ensure correct SPD. See Data

Sheet for specs & wire-outs

2. Determine Mounting location – weather resistant equipment

may be required

3. If SPD has optional Dry Contact and Flush Mount Kit, pre-plan

their installation. See Figures 4&6. (If flush mounting, be careful

to not drop SPD into wall)

4. Remove power from panel/source. Confirm panel/source is

deenergized.

5. Identify breaker location and SPD location. Position SPD such that

LEDs are best visible.

6. Mount SPD – weather resistant applications require additional

sealing, o-rings, etc. (not included)

- Remove an appropriately sized knockout from panel.

- Connect conductors as appropriate – short and straight as possible

(Hi-Legs are Phase B)

- Note that the metallic connection hub is not grounded within the SPD

and proper grounding requires connection of the green conductor

ground.

7. Label or mark conductors as appropriate (neutral: white, ground:

green, energized: black, hi-leg: orange)

8. Make sure system is bonded per NEC

®

and is clear of hazards or

faults before energizing (N-G bonding not per NEC

®

will fail SPDs:

#1 cause of SPD failures)

9. Energize and confirm proper operation of green LED indicators

and/or options.

A

B

C

G

N

BREAKER

• Use closest breaker to SPD

• Locate SPD close to intended

breaker

• Keep Leads Short as Possible

• Avoid Sharp Bends

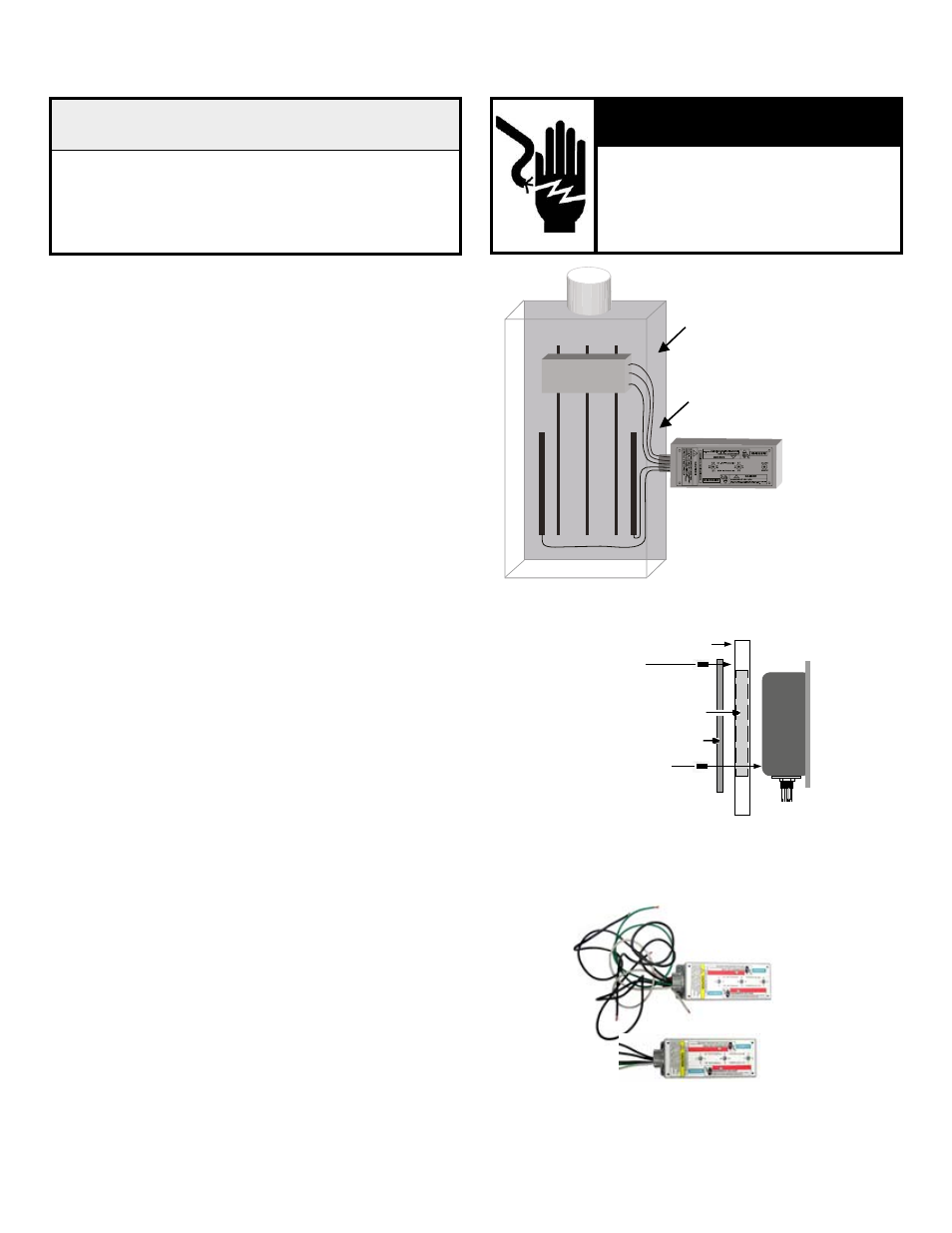

Figure 4: Typical Flush Mount Installation

Phase, Ground,

and Neutral Wires

SPD

Mounting Screws

(4 places, through mountingplate into mounting

surface, screws not provided)

Flush Mount Kit Screws

(8-32 x 5/8” Thread Cutting, 4 places, through

plate into SPD)

Mounting Surface

Removed Material

Flush Mount Plate

Figure 5: Lead Lengths

Leads: Short & Straight

Cut Excess; Do Not Coil or Loop

•

CUT OFF EXCESS

LENGTH

•

DO NOT LOOP OR

COIL

•

SHORT &

STRAIGHT

X

Not

Good

p

Good

CONDUCTING DIELECTRIC AND/OR

HI-POTENTIAL TESTING WILL CAUSE

INTERNAL DAMAGE TO TPS3 UNIT.

Do not perform dielectric or high potential

tests with the TPS3 unit installed.

CAUTION

V

Hazardous voltage.

Will cause death or serious injury.

Keep Out.

Qualified personnel only.

Disconnect and lock off all power before

working on this equipment.

V

DANGER