Inspection of sheaves – Stellar Industries SI-60 User Manual

Page 20

14

Stellar Cable Hoist Owner’s Manual

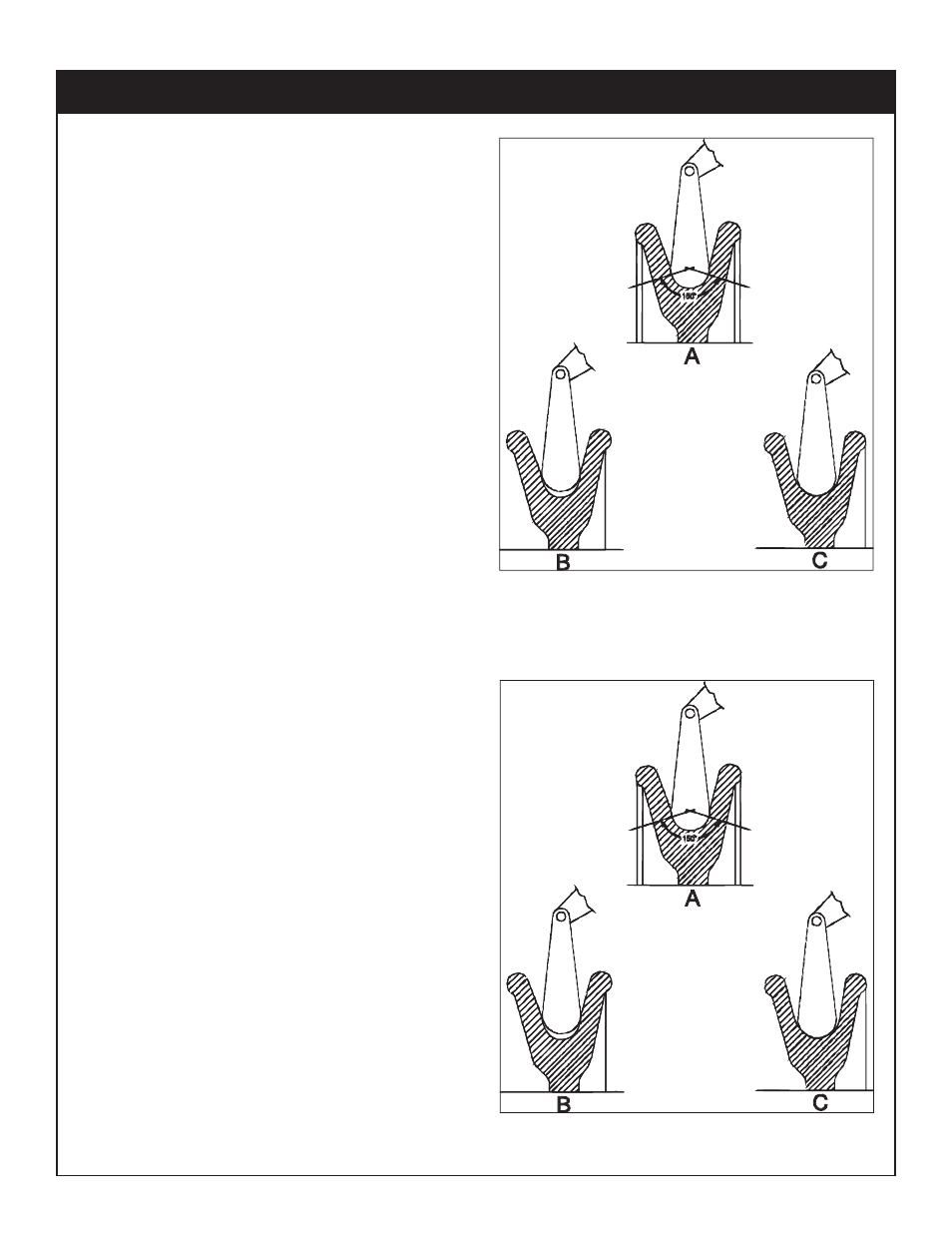

Inspection of Sheaves

Under normal conditions, machines should

receive periodic inspections, and their over-

all condition recorded. Such inspections

usually include the sheaves, and any other

parts that may come into contact with the

wire rope and subject it to wear. As an

additional precaution, rope related working

parts, particularly in the area described

below, should be re-inspected prior to the

installation of a new cable.

The very first item to be checked when

examining the sheaves is the condition of

the grooves. To check the size, contour and

amount of wear, a groove gage is used. As

shown in the illustration to the right of this

paragraph, the gage should contact the

groove for about 150º of arc.

Two types of groove gages are in general

use and it is important to not e which of these

is being used. The two differ by their respec-

tive percentage over nominal.

For new or re-machine grooves, the groove

gage is nominal plus the full oversize per-

centage. The gage carried by most wire

rope representatives today is used for worn

grooves and is made nominal plus 1/2 the

oversize percentage.

The latter gage is intended to act as a sort

of “no-go” gage. Any sheave with a groove

smaller than this must be replaced or, in all

likelihood, the existing rope will be dam-

aged.

Experience has clearly demonstrated that

the service life of the wire rope will be mate-

rially increased by strict adherence to these

standards.

Cross-sections illustrating three sheeve-groove conditions.

A is correct, B is too tight, and C is too loose.

Cross-sections illustrating three sheeve-groove conditions.

A is correct, B is too tight, and C is too loose.