Sdap nomad dryer with ap1 control, Maintenance, Cooling coils: cleaning and replacement procedures – Sterling SDAP User Manual

Page 3: Filters: recommendations for cleaning and

SDAP Nomad Dryer with AP1 Control

Reference Manual (PN: 882.00281.00) for

Complete Operation and Installation Instructions

(Available online at www.sterlco.com)

Sterling

Part No:

682.92636.03

2900 S. 160

th

Street • New Berlin, WI 53151 USA Bulletin No: DH1-315.02

Tel. 262.641.8610 • Fax 262.641.8653

Maintenance

Cooling Coils: Cleaning and Replacement Procedures

1. Shut down the dryer, tag out and lock out the controls if

necessary.

2. Shut the water off to the cooling coil.

3. Remove the four 10-32 bolts.

4. Gently slide the cooling coil out.

5. Visually inspect the coil for leaks, dirt, and any sign of

contaminants.

6. Blow the dust out, or if the coil is covered with plasticizer,

steam clean it.

7. Place the coil back in its housing. Make sure the gasket is

undamaged; replace if necessary.

8. Inset the four 10-32 bolts back in place.

9. Turn the water to the cooling coil back on.

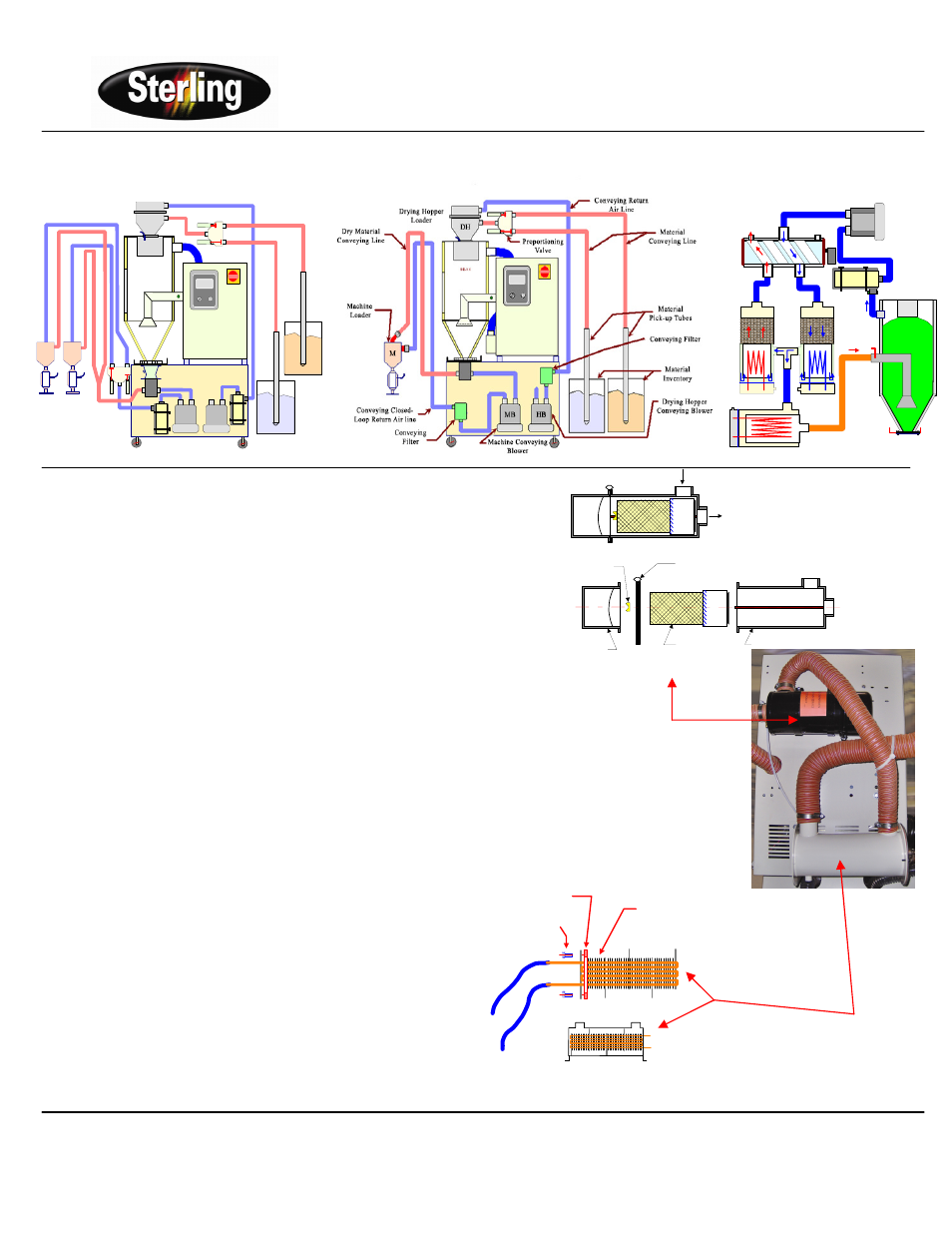

(Return Air Filter)

Filters: Recommendations for Cleaning and

Replacing

1. Turn off and/or lock out electrical power to the dryer.

2. Loosen the clamp, and remove the dust can.

3. Remove the thumb nut, on the center retaining rod, to remove the

filter cartridge.

4. Pull the filter cartridge out.

Vacuuming

•

Try vacuum-cleaning a soiled filter first. Vacuuming removes most

large particles and surface contaminants, and may suffice for the first

time you clean a filter.

•

Use a commercial-duty (recommended) or household vacuum

cleaner. Vacuum the filter from the air intake (dirty) side only.

Cleaning with Compressed Air

1. Blow clean, dry, compressed air up and down the pleats, blowing out

the filter from the inside out.

2. Remove loose dirt from the filter with compressed air or vacuum from

the outside.

3. Inspect the filter element. Briefly hold a light bulb behind the element

and look for any fatigued paper or residual dirt. Inspect for holes and

tears by looking though the filter toward a bright light. Check for

damaged gaskets or dented metal parts.

Note: Do not re-use a damaged filter!

Thumb Nut

Clamp

Dust Can

Filter

Cartridge

Filter Housing

Air In

Air Out

(Cooling Coil)

Undo (4) 10-32 Button

Head Screws using 1/8

Allen Wrench

Use compressed air or a steam

cleaner to blow the dust off or

clean any oily residue on the coil.

1" Wide x 1/8" Thick High

Temperature Gasket

Water flow requirement:

If used as an After-Cooler: 3 to 4 GPM @80°F.

If used as a Plasticizer Trap: 3 to 4 GPM @ 40°F to

45°F.

(Air Flow Schematic)

Process

Heater

Desiccant

Tanks

Filter

Blower

Valve

T’Couple

Location

Slide

Gate

ON

O

F

F

M1

DH

M1

HB

Hopper

Blower

MB

Machine

Blower

Drying Hopper

Loader

Machine 1

Loader

Machine 2

Loader

Convey to Drying Hopper With

Proportioning Valve & Two

Machines, Configuration “DP”

Convey to Drying Hopper With

Proportioning Valve & Two

Machines, Configuration “CP”