Application data, Dimensions – Siemens FP-11 User Manual

Page 3

system alarm functions programmed into the system

are activated. Each FP-11 detector can operate one

remote alarm indicator, one auxiliary relay, or one

audible base.

Detector sensitivity, calibration, and identification are

dynamically supervised by the control panel. Detector

sensitivity and pre-alarm levels are a function of the

application chosen at the control panel and are

controlled by the panel. If an alternate, non-FirePrint

mode is selected, then the sensitivity can be changed

from the control panel.

The DPU or FPI-32 Program/Test accessory is used to

program and verify the detector’s address. The

technician selects the accessory’s program mode to

enter the desired address. The DPU or FPI-32 auto-

matically sets and verifies the address and tests the

detector. It also allows the user to change the device

ID from that of an FP-11 to an older detector ID such as

an ILP-1, ILPT-1, ILP-2, ID-60P or ID-60PT to allow for

easy replacement of older detectors without the need

of reprogramming the control panel.

The FPI-32 operates on AC power or rechargeable

batteries, providing flexibility and convenience in

programming and testing equipment almost anywhere.

When in the test mode, the DPU or FPI-32 will perform

a series of diagnostic tests without altering the

address or other stored data, allowing technicians to

determine if the detector is operating properly.

The FP-11 fire detector may be installed on the same

initiating circuit with IL or ID series detectors (Photo-

electric, thermal, or ionization), MSI series manual

stations, TRI series interfaces, ICP output control

devices, or CZM series of addressable, conventional

zone modules.

All FP-11 detectors can be cleaned in the field, when

required, by simply removing the detector cover and

unsnapping the photo chamber. There is also the

option of cleaning the interior of the detector with a

clean, soft cloth or brush, or replacing the labyrinth and

bug screen included in the detector maintenance kit,

model DMK-11.

The FP-11 uses the low profile surface mounting base,

model DB-11. This base mounts on a 4-inch octagon,

square, or a single gang electrical box. The base

utilizes screw clamp contacts for electrical connections

and self-wiping contacts for increased reliability. The

base can be used with the optional LK-11 detector

locking kit which contains 50 detector locks and an

installation tool, to prevent unauthorized removal of

the detector head. The DB-11 base has integral decora-

tive plugs to cover the outer mounting screw holes.

The FP-11 is electrically compatible with existing MXL

detector accessories including relays, remote lamps,

duct housings, and audible bases. With duct housings,

a base adapter and new detector housing cover are

required (order AD-11UK upgrade kit). To use existing

DB-3S base or audible base, the FP-11 requires a DB-

ADPT base adapter.

All FP-11 detectors are approved for operation within

the UL specified temperature range of 32 to 100

degrees F (0 to 38 degrees C).

Application Data

Installation of the FP-11 series of fire detectors

requires a two-wire circuit of 18 AWG (minimum)

thermoplastic fixture wire enclosed in conduit, or 18

AWG limited energy, shielded cable without conduit,

if permitted by local codes. Field wiring should

conform to local and National Electric Codes and the

control panel wiring specifications.

“T-tapping” is permitted only for Style 4 (Class B)

wiring.

FP-11 fire detectors can be applied within the maxi-

mum 30 foot center spacing (900 sq. ft. areas) as

referenced in NFPA 72. This applications guideline is

based on ideal conditions, specifically, smooth ceiling

surfaces, minimal air movement, and no physical

obstructions between potential fire sources and the

detector. Do not mount detectors in close proximity

to ventilation or heating and air conditioning outlets.

Exposed joints or beamed ceilings may also affect safe

spacing limitations for detectors. Should questions

arise regarding detector placement, observe NFPA

72 guidelines.

Good fire protection system engineering and common

sense dictate how and when fire detectors are

installed and used. Contact your local Siemens

Building Technologies, Fire Safety Division authorized

sales outlet whenever you need assistance applying

FirePrint in unusual applications. Be sure to follow

NFPA guidelines, UL/ULC approved installation

instructions, which are included with every detector,

and local codes as for all fire protection equipment.

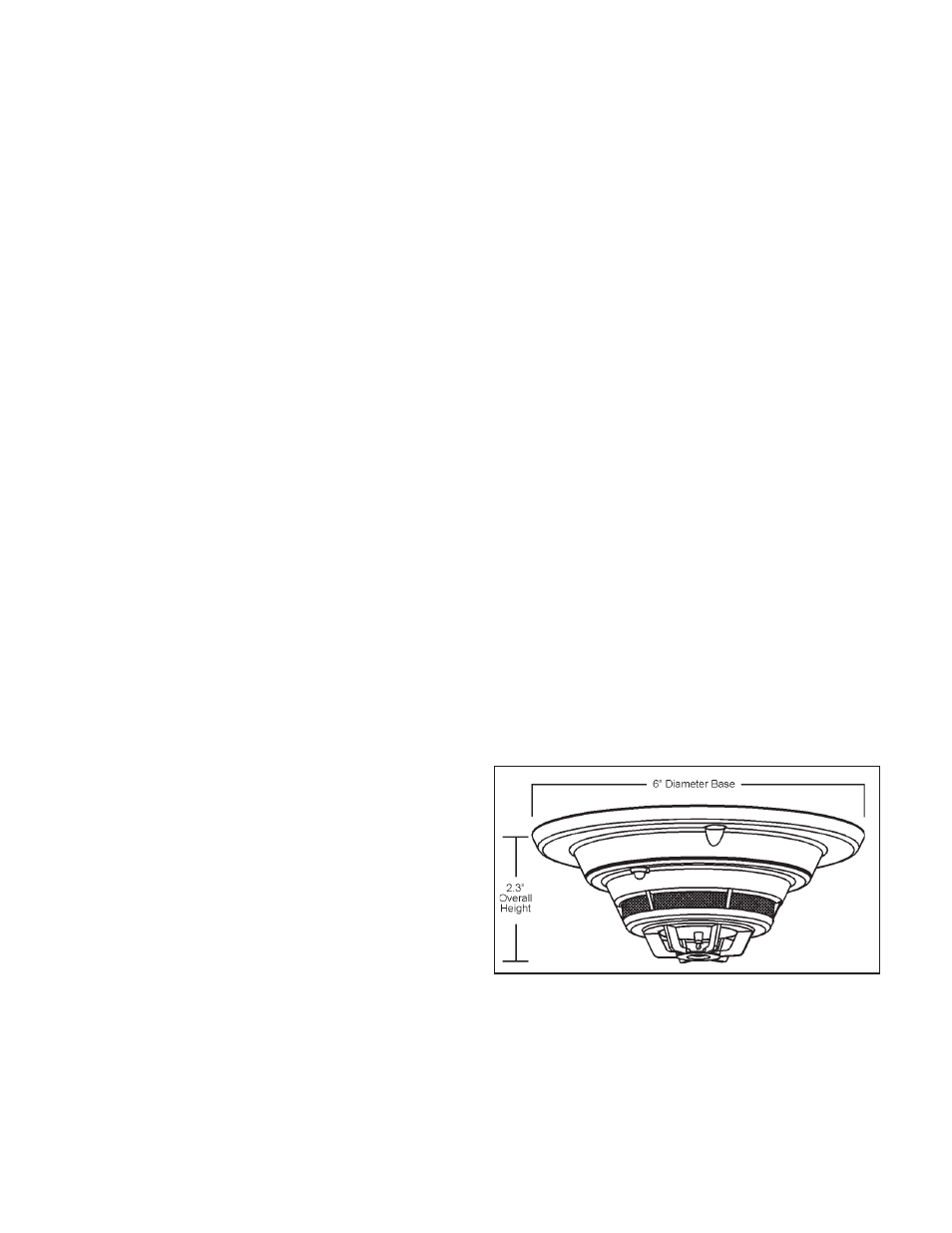

Dimensions