0 troubleshooting – Simpson PS3000 User Manual

Page 11

6.0

Troubleshooting

www.simpsoncleaning.com

page 11

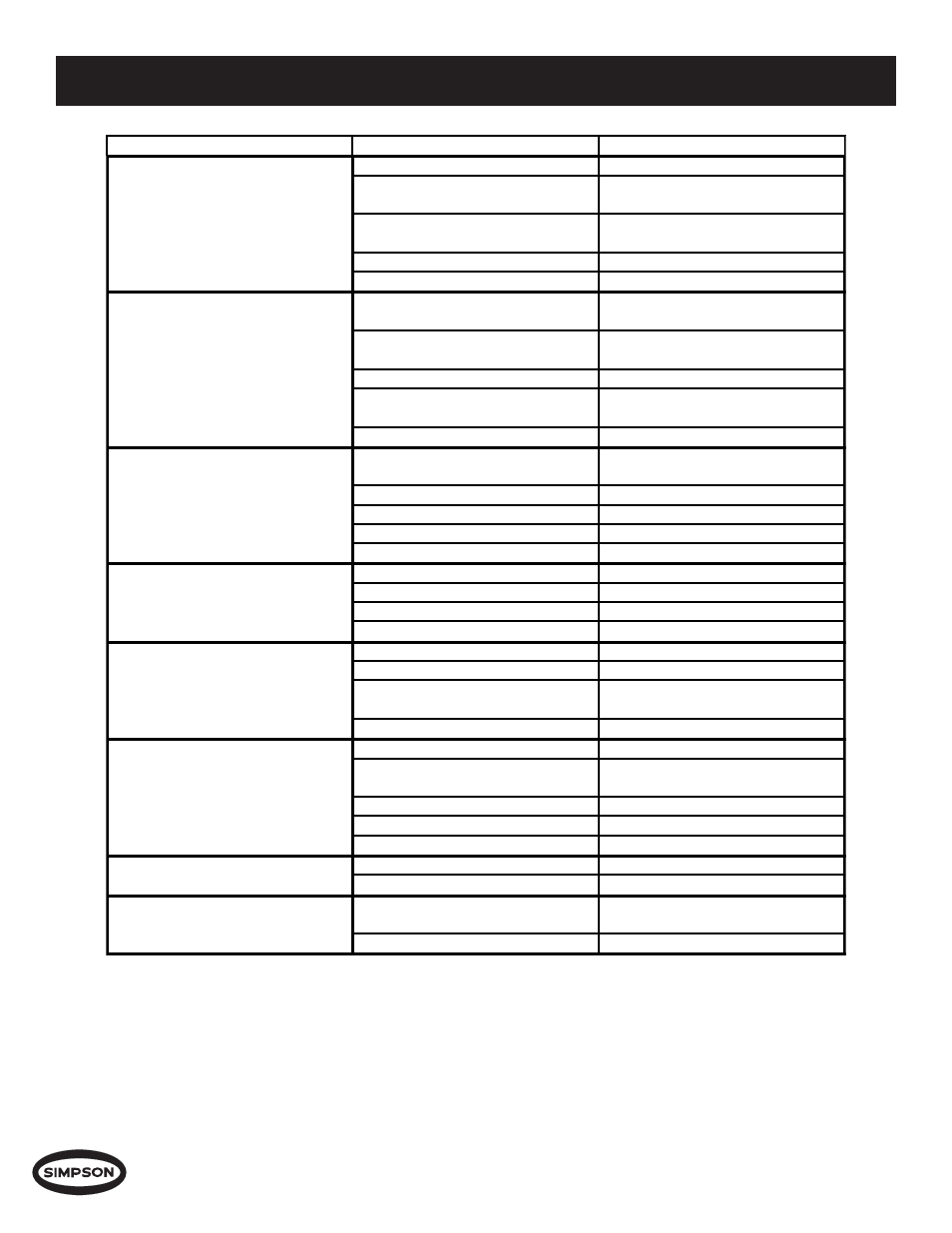

PROBLEM

PROBABLE CAUSE

SOLUTION

Broken Belts (if Applicable)

Replace Belts

Im proper Belt Tension (if

Applicable)

Adjust Belt Tension

No Pressure

Clogged Inlet W ater Filter

Clean or Replace W ater Inlet Filter

Clogged Nozzle

Clean Debris from Nozzle

W orn or Incorrect Nozzle

Replace Nozzle with Correct Size

Im proper Belt Tension (if

Applicable

Adjust Belt Tension

Low Pressure

Im proper Engine R.P.M .

Consult Service Center

Inadequate W ater Supply

Check W ater Supply and Clean

Inlet Filter

Inadequate W ater Supply

Check W ater Supply and Inlet

W ater Filter

Partially Clogged Nozzle

Clean or Replace Nozzle

Pulsation or Hoses Vibrating

Debris in Pum p Valves

Consult Service Center

Incorrect Nozzle Size

Install Correct Size Nozzle

W orn Plunger Seals

Consult Service Center

W ater Leaking Under Pum p

W orn or Dam aged Plungers

Consult Service Center

Pum p Running Dry

Check W ater Supply

W orn Pum p Seals

Consult Service Center

W ater in Pum p O il

W orn or Dam aged Plungers

Consult Service Center

Condensation in Pum p Crankcase

Change O il

O il Level Too High

Drain O il and Fill to Proper level

W rong O il Type

Drain O il and Fill with Correct O il

Sim pson 30 W T Non-Detergent

Pum p O il Leak

O perating on Unlevel Surface

M ove To Level Surface

Tire Pressure Too Low or Flat

Inflate Tire or Repair Leak

Recoil Starter Hard to Pull

Pressure Built up in System

Pull Trigger while Starting Unit

Engine Dies W hen Trigger is

Released

Unloader Valve is Broken or

M isadjusted

Consult Service Center